Hazy Cognition

Member

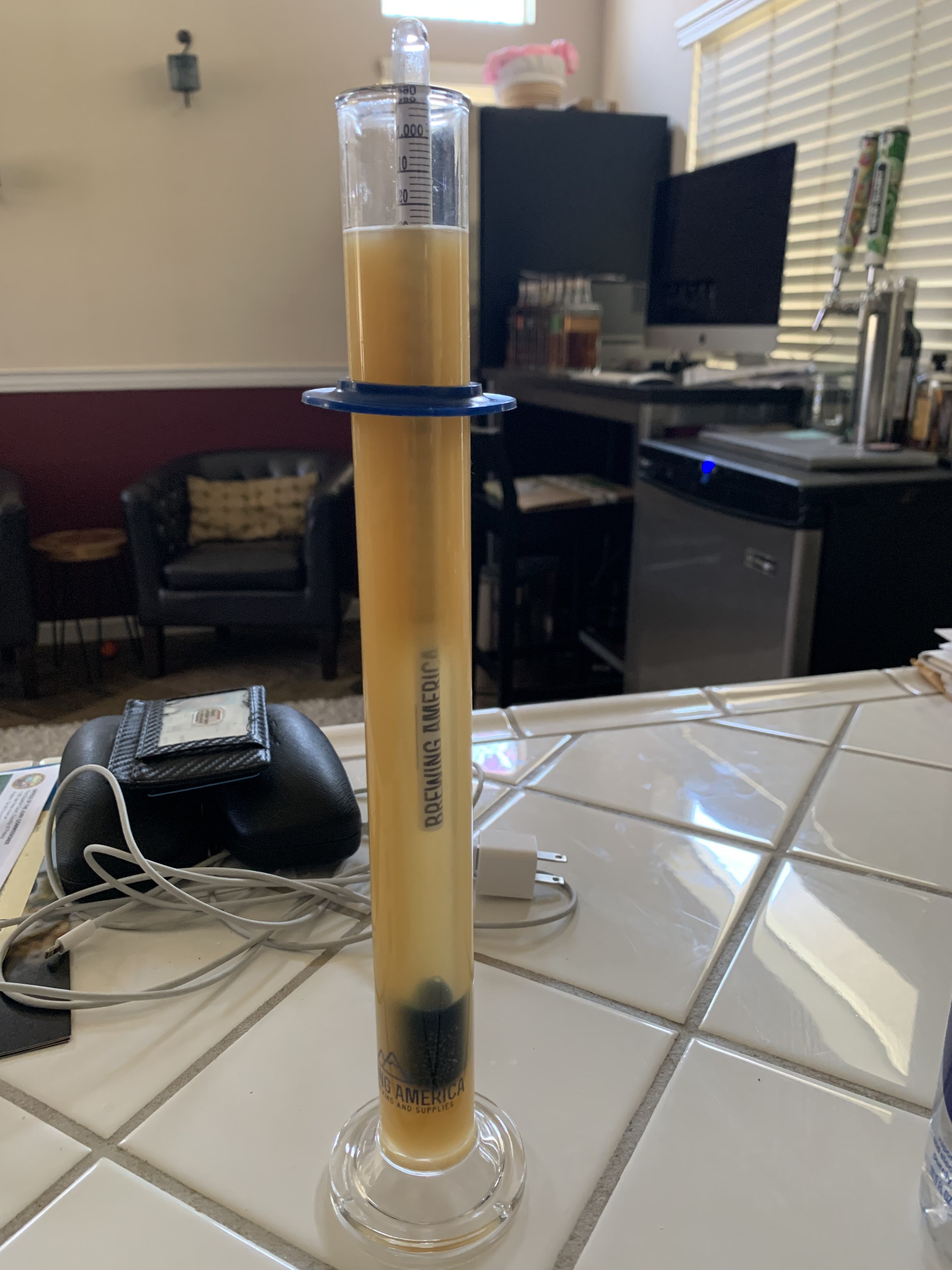

So I have been out of the homebrewing hobby for over a decade due to family obligations as my kids were growing/coaching etc. Anyhow, my son who is 26 has been asking me to get back to brewing and to show him how to brew. The problem is that we both really like NEIPAs a lot. Well I am sure you can imagine that being out of the game I never brewed NEIPAs so the learning along the way by reading the very informative threads here. Well, long story short, after pitching the A38 Juice yeast we managed to haul the converted 15.5 gallon beer company keg with a corny keg top and ball lock posts. I was placing the blow off tube into a large bottle of starsan solution and getting ready to hook up to the blowoff port. THIS is where I blew it. I read the post that said "out" and I placed the gas blow out connection here. Yikes! Well the next day I went to the chest freezer temp controled to check on the fermentation. Nothing. So I thought maybe I need to put in some CO2 and check for seals and hope there aren't any leaks. I grabbed the CO2 5lb tank - took off the blowoff connection from the "out". I then turned on the CO2 tank and purged the connector by pushing in the piston and let some CO2 blow out and to check the valve with the psi and dialed it to 2 to 3 psi. to check. I connected that to the "out" post. Before I knew it, gas was chugging below and with thumps. I know I screwed up. I purged it quik but felt I had just CO2'ed my oxygen wort. I waited until the next day in the hopes that it would recover. It did not. So....I did what I could only think at the time. I took my clean sanitized 5 gal corny key and began pushing the wort into the empty keg and splash/oxygenate it. Then, I closed that keg up and pushed it back into the fermentor and splashed more. I hit it with a new A38 Juice yeast pack and within the hour it was fermenting good! Fast forward to today 5 days post the debacle for a gravity check. Beer smelled good and clean with some hop aroma. Gravity was 1.028 (SG was 1.082). I noticed that the beer in the hydrometer was a bit dark, oxygenated? Damn....it taste good but need a ton of dry hop. So tomorrow after nood my son and I are ok with the gravity where it will land, and we will do a soft crash to 52 to 55 degrees and hop dry hop the heck out of this, I hear crushing the hop pellets and dump in so they don't sink. So...we may give that a go. After 4 days of this, we will cold crash to 34 degrees and transfer to keg to condition and dispense.

So...moral of this story, experience guy here who made a major rookie mistake and hopefully we can recover a messed up beer. Learning and learning, rusty as heck and hard to admit I screwed up. Never again will I make this mistake again.

If you have any questions post em and I will try and reply as soon as possible. Comment away too, I am always up for constructive feedback.

Cheers everyone. I'll post a pic of the hydrometer so you can see the color.

hazy Cognition at it's finest!

So...moral of this story, experience guy here who made a major rookie mistake and hopefully we can recover a messed up beer. Learning and learning, rusty as heck and hard to admit I screwed up. Never again will I make this mistake again.

If you have any questions post em and I will try and reply as soon as possible. Comment away too, I am always up for constructive feedback.

Cheers everyone. I'll post a pic of the hydrometer so you can see the color.

hazy Cognition at it's finest!

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/417FujUfrWL._SL500_.jpg)