Imhoppy

Well-Known Member

- Joined

- Aug 7, 2019

- Messages

- 352

- Reaction score

- 788

Just tapped a full 5-gallon keg of Dry Irish Stout. But there is excessive foaming from the Intertap faucet (with a self-closing spring installed). Pressure is set at 12 psi and temperature at 42F. Note the other keg is pressurized from the same CO2 source, pours fine, and has a self-closing spring installed on an Intertap faucet). After letting things settle down after drawing a sample glass, the next day there is some gas visible in the liquid line.

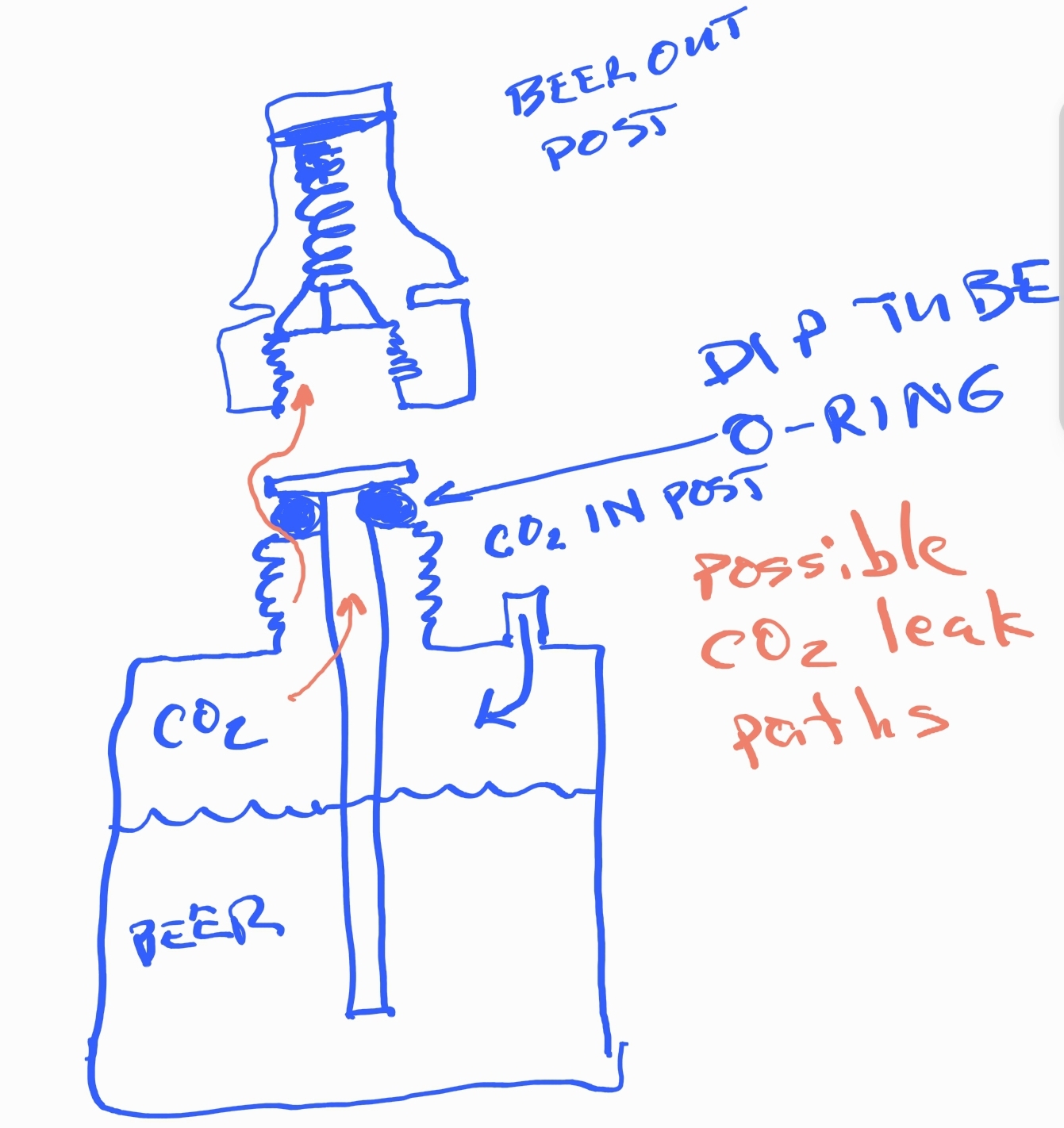

I have replaced the o-ring on the beer line outlet dip tube, thinking there might be gas leaking past a bad o-ring and into the liqiud line. But this has not solved the problem.

Never had this issue come up before, so I am at a loss as to why the foaming and gas bubbles appear in the liquid line. Maybe the dip tube has a pinhole leak above the liquid line? Seems unlikely, but I might try and replace the dip tube as my next course of action. I have used this keg numerous times without any problems before. Anyone have some other suggestions as to what the issue could be?

I have replaced the o-ring on the beer line outlet dip tube, thinking there might be gas leaking past a bad o-ring and into the liqiud line. But this has not solved the problem.

Never had this issue come up before, so I am at a loss as to why the foaming and gas bubbles appear in the liquid line. Maybe the dip tube has a pinhole leak above the liquid line? Seems unlikely, but I might try and replace the dip tube as my next course of action. I have used this keg numerous times without any problems before. Anyone have some other suggestions as to what the issue could be?

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)