Brian Parfitt

Well-Known Member

- Joined

- Apr 17, 2020

- Messages

- 45

- Reaction score

- 4

Hello all,

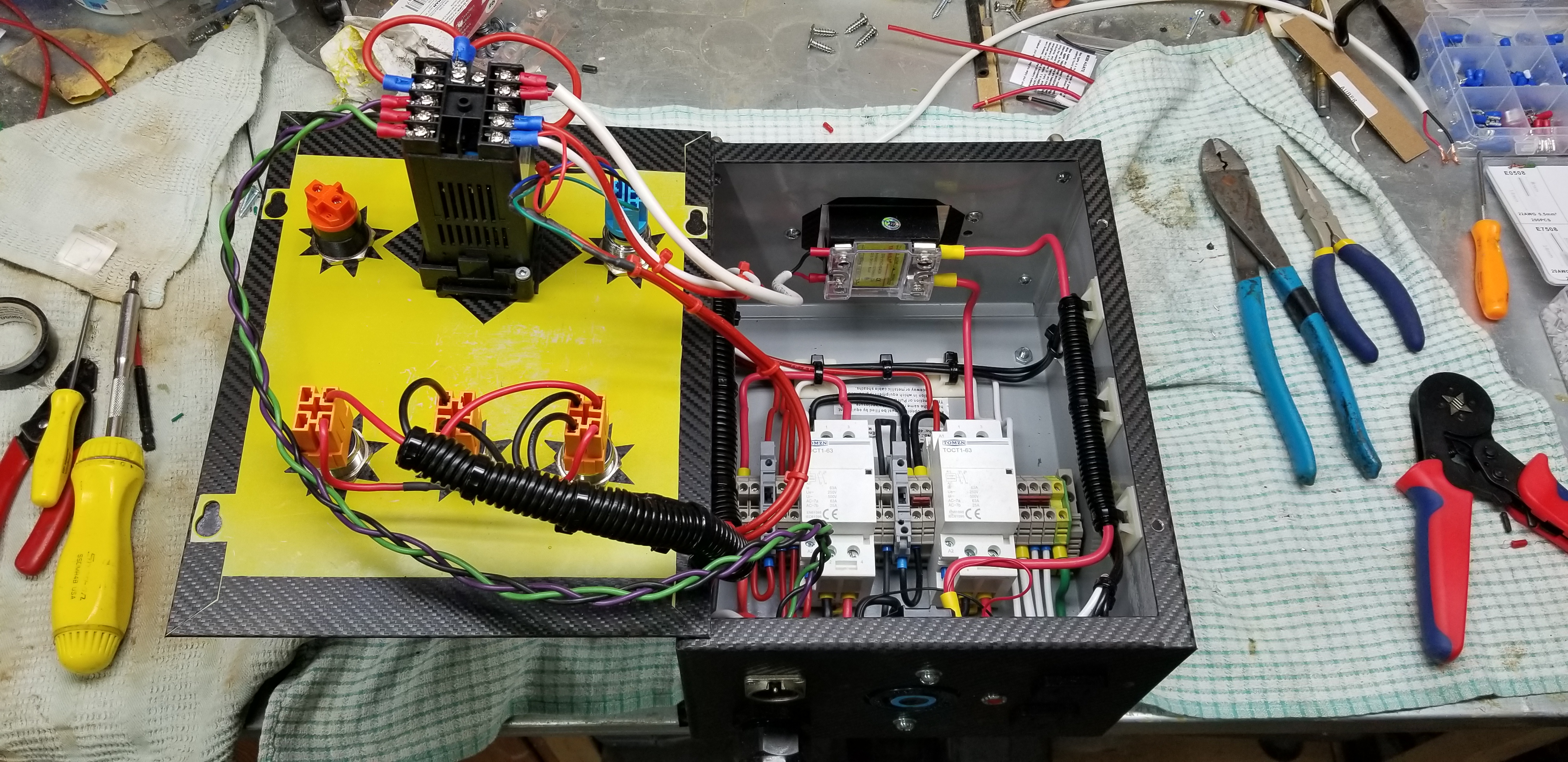

I'm starting a conversion to electric brewing and am basing my build on craftbeerpi and a diy panel. I'm looking for some 'packaging' or finishing help with the electrical inside the panel. While I have a lot of experience with breadboard prototyping and hobby builds, I'd like this project to have a more 'finished' look to it. i.e. not wire spaghetti.

I plan on using this box to house the electronics:

Bud Industries Enclosure

My plan is to use some DIN mount components (contactors, SSRs, terminal strips) to keep things tidy. Do I just screw the rail into the back of the plastic box, or do people typically use a backing plate?

Would folks be willing to share photos of completed control panel innards utilizing DIN rail mounts along with some details on how things were mounted/organized in the panel?

Again, my goal here is to up my game around how the project looks when it is finished.

Thanks in advance.

Brian

I'm starting a conversion to electric brewing and am basing my build on craftbeerpi and a diy panel. I'm looking for some 'packaging' or finishing help with the electrical inside the panel. While I have a lot of experience with breadboard prototyping and hobby builds, I'd like this project to have a more 'finished' look to it. i.e. not wire spaghetti.

I plan on using this box to house the electronics:

Bud Industries Enclosure

My plan is to use some DIN mount components (contactors, SSRs, terminal strips) to keep things tidy. Do I just screw the rail into the back of the plastic box, or do people typically use a backing plate?

Would folks be willing to share photos of completed control panel innards utilizing DIN rail mounts along with some details on how things were mounted/organized in the panel?

Again, my goal here is to up my game around how the project looks when it is finished.

Thanks in advance.

Brian

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)