/////////////////////////////////START/////////////////////////////////////////////////////

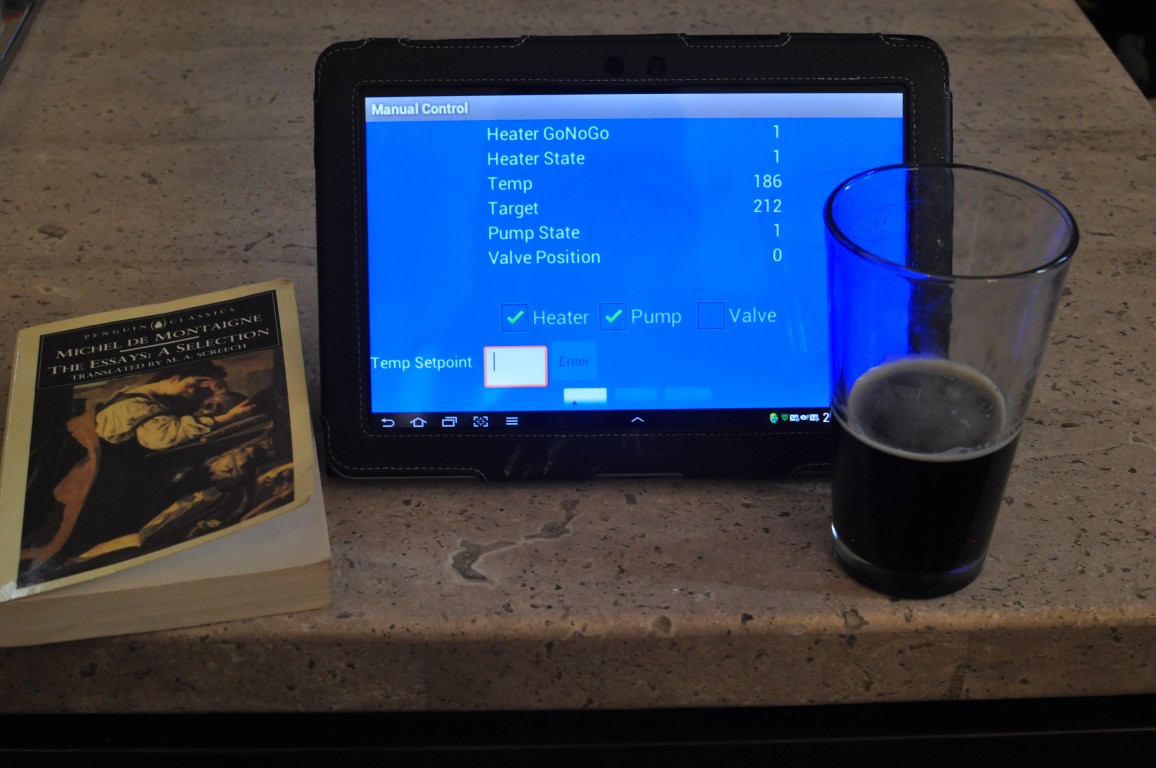

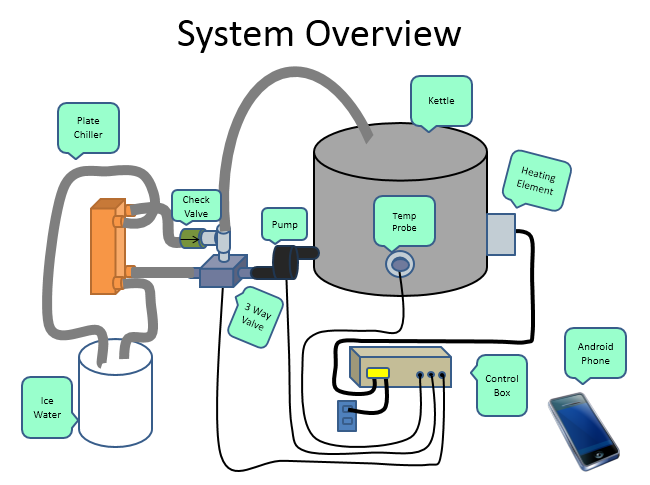

int PinTemp = 0; // LM34 temperature sensor

int PinHeater = 13; //SSR control for heating element

int PinPump = 8; //pump control

int PinValve = 10; //valve control

float timer = 0;

String decimal = ""; //string for placing decimals

int state; //used for setting heater, pump, and valve states from app

char ascii; //used to convert ascii byte to decimal

char ack; //used for communication acknowledgment with android app

int target; //varaible for target temp

int gonogo; //general variable for no and no go situations

float signal;

float millivolts;

int temp;

int heater;

int pump;

int valve;

/////////////////////////////////SETUP/////////////////////////////////////////////////////

void setup() // put your setup code here, to run once:

{

//Set pin modes

pinMode (PinTemp, INPUT); //set temperature sensor pin as input

pinMode (PinHeater, OUTPUT); //set heater pin as output

pinMode (PinPump, OUTPUT); //sets pump pin as output

pinMode (PinValve, OUTPUT); //sets valve pin as output

digitalWrite (PinHeater, LOW); //heat init to off

digitalWrite (PinPump, HIGH); //pump init to off

digitalWrite (PinValve, HIGH); //vavle init to pos A

gonogo = 0; //disables heater at begining

Serial1.begin(9600);// opens serial port, sets data rate to 9600 bps

}

////////////////////////////////////LOOP///////////////////////////////////////////////////////

void loop() // put your main code here, to run repeatedly:

{

Handshake(); //waits for clocktimer in app to send a handshake byte

Variables(); //collects variables that have been written to serial from app

Status();//run status subrotine to report variables back to app

if (gonogo == 1) //When gonogo is set to 1, control heating element based on target temp and actual temp

{

if (temp < target) //if the temperature is less than target, then

{

digitalWrite (PinHeater, HIGH); //turn the heating element on, otherwise

heater = 1;

}

else

{

digitalWrite (PinHeater, LOW); //turn it off

heater = 0;

}

}

else {

digitalWrite (PinHeater, LOW); //if nogono is 0 then disable heater

heater = 0;

}

}

///////////////////////////HANDSHAKE SUBROUTINE//////////////////////////////////////////////////////////////////////

void Handshake()

{

ack = Serial1.read(); //reads any available byte from serial

while (ack != 'A') //loops until handshake byte is recieved from app

{ack = Serial1.read();}

Serial1.print('B'); //returns handshake byte to app

ack = 'B'; //sets ack to force program to wait for next handshake byte from app

}

///////////////////////////////VARIABLES SUBROUTINE//////////////////////////////////////////////////////////////////////

void Variables() //sets & toggles variables

{

while (Serial1.available() == 0) //loops until variables from app are available

{delay(500);}

state = Serial1.read(); //stores heater, pump, and valve states from app

if (state == 1) //checks if heater is on or off

{

gonogo = 1; //sets gonogo to 1 so heater will turn on using temp control algorithym

}

else

{

gonogo = 0; //sets gonogo to 0 so heater won't turn on, regardless of temp control algorithym

}

state = Serial1.read(); //stores heater, pump, and valve states from app

if (state == 1) //checks if pump is on or off

{

digitalWrite(PinPump,LOW); //turn pump on

pump = 1;

}

else {digitalWrite(PinPump, HIGH);

pump = 0;} //turn pump off

state = Serial1.read(); //stores heater, pump, and valve states from app

if (state == 1) //checks if valve is pos A or B

{

digitalWrite(PinValve, LOW); //turn valve pos A

valve = 1;

}

else {digitalWrite(PinValve, HIGH);

valve = 0;} //turn valve pos B

while (Serial1.available() > 0) //collects all bytes for target temp and inserts into sring

{

ascii = Serial1.read();

ascii=ascii-0;

decimal += ascii;

}

target = decimal.toInt();// sets target to value that user entered in serial

decimal = ""; //clears string for future use

}

/////////////////////////////////////STATUS SUBROUTINE//////////////////////////////////////////

void Status() //reports the status of each variable back to app

{

Serial1.print(gonogo); //gonogo status

Serial1.print('C'); //delimeter

Serial1.print(heater);

Serial1.print('C'); //delimeter

Serial1.print(target); //print target temp

Serial1.print('C');

//Convert to deg F and display in serial

signal = analogRead(PinTemp); //read signal on AO1 and store as "signal"

millivolts = (signal/1024.0)*5000; //signal is divided by 1024 (resolution) and multiplied by 5000mV to get voltage

temp = millivolts/10; //converts voltage to temperature since there is 10mV per deg F

Serial1.print(temp); //print actual temp

Serial1.print('C');

Serial1.print(pump);

Serial1.print('C'); //delimeter

Serial1.print(valve);

Serial1.print('C'); //delimeter

}

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)