I am planning to make the 999 barleywine and the recipe calls for 27lbs of grain. My typical efficiency for a 15lb grist is around 75%. So it seems like the expected efficiency for this BW is like 65%. I am imagining that if I knock down the amount of base malts, then my efficiency will go up. What is the point of creating a recipe with so much grains that it drops the efficiency when you can put less grains, get higher efficiency, and be able to still extract the same amount of sugars? What am I missing?

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Efficiency and grain size

- Thread starter urg8rb8

- Start date

Help Support Homebrew Talk:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

Very high OGs typically leave high residual sugars behind in the mash because unless you want to add an hour or two to the boil there's not enough sparging to extract it all.

For example, I did an 11 gallon batch of 1.105 stout last week. With 44 pounds of grain and just 1.25 quarts per pound I needed 12.75 gallons of strike water, which resulted in almost 8 gallons of first runnings. With a planned pre-boil volume of 13.5 gallons that didn't leave much for sparging - only ~5.75 gallons - and you're not going to pull the last runnings down much below 1.020 with that little sparging.

Otoh, for my more typical 65-70 point brews I can end up with the last runnings between 1.006 and 1.010. Much less sugar left behind...

Cheers!

For example, I did an 11 gallon batch of 1.105 stout last week. With 44 pounds of grain and just 1.25 quarts per pound I needed 12.75 gallons of strike water, which resulted in almost 8 gallons of first runnings. With a planned pre-boil volume of 13.5 gallons that didn't leave much for sparging - only ~5.75 gallons - and you're not going to pull the last runnings down much below 1.020 with that little sparging.

Otoh, for my more typical 65-70 point brews I can end up with the last runnings between 1.006 and 1.010. Much less sugar left behind...

Cheers!

Last edited:

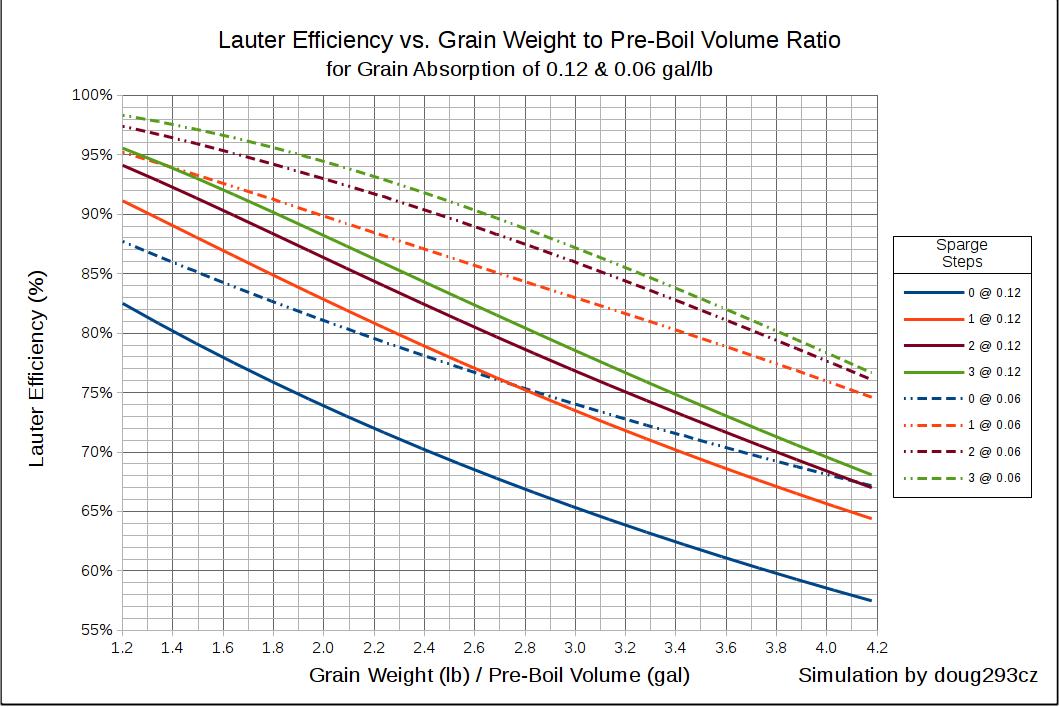

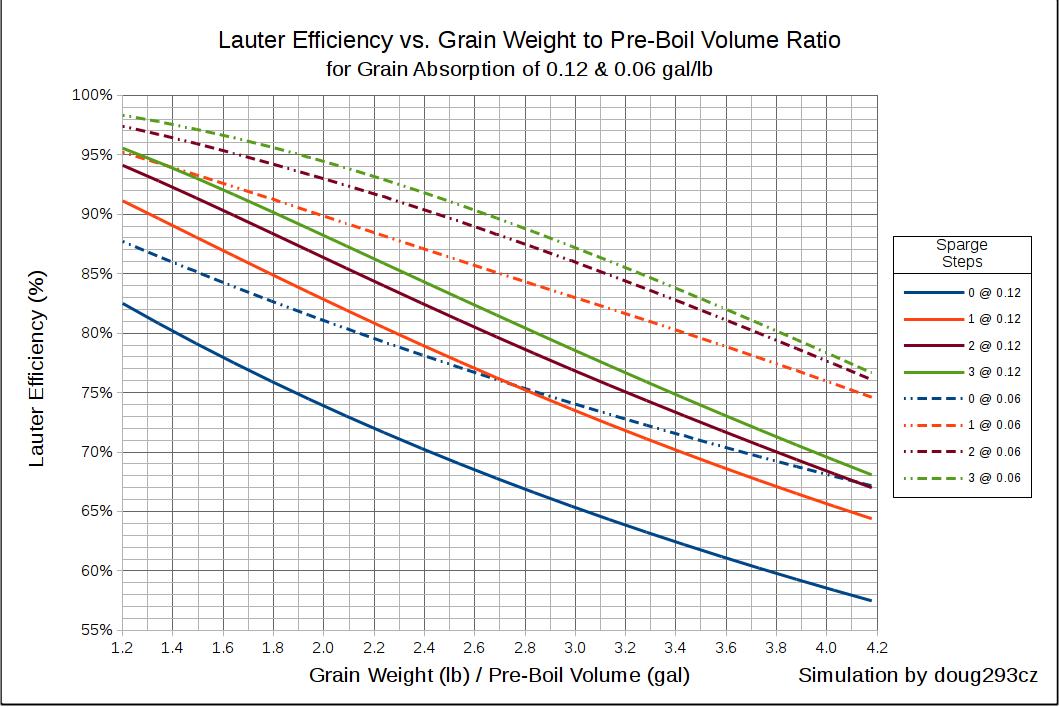

Efficiency drops off with increasing size grain bills since the larger amount of grain absorbs a larger fraction of the total wort created in the mash. Turns out for a given process (number of sparge steps, pre-boil volume, grain absorption rate, conversion efficiency) the lauter efficiency is a function of grain weight divided by pre-boil volume. A 6 gal pre-boil volume made from 12 lb of grain (ratio = 2) will have the same lauter efficiency as a 12 gal pre-boil volume made with 24 lb of grain.

The lauter efficiency can be calculated for batch and no-sparge processes as a function of number of sparges, weight/volume ratio, and grain absorption rate. The following chart shows how lauter efficiency looks for 0, 1, 2 & 3 sparges at two different grain absorption rates - 0.12 gal/lb (typical for an MLT) and 0.06 gal/lb (typical with hard squeezed BIAB.)

Let's do a simple example. Let's say you used 15 lb of grain and had 7.5 gal pre-boil volume. The grain weight to pre-boil volume ratio is 2.0. now if you used 27 lb with the same 7.5 gal pre-boil, the ratio would be 3.6. Looking at the charts, going from a ratio of 2.0 to 3.6 reduces the lauter efficiency by about 13 percentage points, independent of sparge count, for typical MLT absorption rates.

So if you were getting 75% mash efficiency with 15 lb grain bills, you'd get about 62% with a 27 lb grain bill.

Given the details of a particular process if is possible to predict the lauter efficiency for different grain bill weights and pre-boil volumes. The spreadsheet available here will do those calculations.

Brew on

The lauter efficiency can be calculated for batch and no-sparge processes as a function of number of sparges, weight/volume ratio, and grain absorption rate. The following chart shows how lauter efficiency looks for 0, 1, 2 & 3 sparges at two different grain absorption rates - 0.12 gal/lb (typical for an MLT) and 0.06 gal/lb (typical with hard squeezed BIAB.)

Let's do a simple example. Let's say you used 15 lb of grain and had 7.5 gal pre-boil volume. The grain weight to pre-boil volume ratio is 2.0. now if you used 27 lb with the same 7.5 gal pre-boil, the ratio would be 3.6. Looking at the charts, going from a ratio of 2.0 to 3.6 reduces the lauter efficiency by about 13 percentage points, independent of sparge count, for typical MLT absorption rates.

So if you were getting 75% mash efficiency with 15 lb grain bills, you'd get about 62% with a 27 lb grain bill.

Given the details of a particular process if is possible to predict the lauter efficiency for different grain bill weights and pre-boil volumes. The spreadsheet available here will do those calculations.

Brew on

Damn.... I just got a hard-on lolEfficiency drops off with increasing size grain bills since the larger amount of grain absorbs a larger fraction of the total wort created in the mash. Turns out for a given process (number of sparge steps, pre-boil volume, grain absorption rate, conversion efficiency) the lauter efficiency is a function of grain weight divided by pre-boil volume. A 6 gal pre-boil volume made from 12 lb of grain (ratio = 2) will have the same lauter efficiency as a 12 gal pre-boil volume made with 24 lb of grain.

The lauter efficiency can be calculated for batch and no-sparge processes as a function of number of sparges, weight/volume ratio, and grain absorption rate. The following chart shows how lauter efficiency looks for 0, 1, 2 & 3 sparges at two different grain absorption rates - 0.12 gal/lb (typical for an MLT) and 0.06 gal/lb (typical with hard squeezed BIAB.)

View attachment 589416

Let's do a simple example. Let's say you used 15 lb of grain and had 7.5 gal pre-boil volume. The grain weight to pre-boil volume ratio is 2.0. now if you used 27 lb with the same 7.5 gal pre-boil, the ratio would be 3.6. Looking at the charts, going from a ratio of 2.0 to 3.6 reduces the lauter efficiency by about 13 percentage points, independent of sparge count, for typical MLT absorption rates.

So if you were getting 75% mash efficiency with 15 lb grain bills, you'd get about 62% with a 27 lb grain bill.

Given the details of a particular process if is possible to predict the lauter efficiency for different grain bill weights and pre-boil volumes. The spreadsheet available here will do those calculations.

Brew on

This is why I love brewing! I love engineering, cooking, and beer. And this hobby puts it all together for me!

Efficiency drops off with increasing size grain bills since the larger amount of grain absorbs a larger fraction of the total wort created in the mash. Turns out for a given process (number of sparge steps, pre-boil volume, grain absorption rate, conversion efficiency) the lauter efficiency is a function of grain weight divided by pre-boil volume. A 6 gal pre-boil volume made from 12 lb of grain (ratio = 2) will have the same lauter efficiency as a 12 gal pre-boil volume made with 24 lb of grain.

The lauter efficiency can be calculated for batch and no-sparge processes as a function of number of sparges, weight/volume ratio, and grain absorption rate. The following chart shows how lauter efficiency looks for 0, 1, 2 & 3 sparges at two different grain absorption rates - 0.12 gal/lb (typical for an MLT) and 0.06 gal/lb (typical with hard squeezed BIAB.)

View attachment 589416

Let's do a simple example. Let's say you used 15 lb of grain and had 7.5 gal pre-boil volume. The grain weight to pre-boil volume ratio is 2.0. now if you used 27 lb with the same 7.5 gal pre-boil, the ratio would be 3.6. Looking at the charts, going from a ratio of 2.0 to 3.6 reduces the lauter efficiency by about 13 percentage points, independent of sparge count, for typical MLT absorption rates.

So if you were getting 75% mash efficiency with 15 lb grain bills, you'd get about 62% with a 27 lb grain bill.

Given the details of a particular process if is possible to predict the lauter efficiency for different grain bill weights and pre-boil volumes. The spreadsheet available here will do those calculations.

Brew on

So basically what this chart is telling me is that my efficiency sucks. I do a mash and a single sparge. So theoretically that brew with the 14# of grain should have given me much higher efficiency than 75%.

That's possible. The spreadsheet tells you what you should get for lauter efficiency. You can then work backward (the spreadsheet will do this using goal seek) from your pre- or post-boil SG to get your conversion efficiency. Mash efficiency is conversion efficiency times lauter efficiency. So, it looks like your conversion efficiency is low, since it's easy to do a close to optimal batch sparge. The usual culprit with low conversion efficiency is a mash time too short to completely convert the grain at its crushed size. The easiest way to increase conversion efficiency is to crush finer, rather than mash longer (since with longer mashes, the enzyme activity is diminishing.)So basically what this chart is telling me is that my efficiency sucks. I do a mash and a single sparge. So theoretically that brew with the 14# of grain should have given me much higher efficiency than 75%.

Brew on

$7.79 ($7.79 / Count)

Craft A Brew - LalBrew Voss™ - Kveik Ale Yeast - For Craft Lagers - Ingredients for Home Brewing - Beer Making Supplies - (1 Pack)

Craft a Brew

$33.99 ($17.00 / Count)

$41.99 ($21.00 / Count)

2 Pack 1 Gallon Large Fermentation Jars with 3 Airlocks and 2 SCREW Lids(100% Airtight Heavy Duty Lid w Silicone) - Wide Mouth Glass Jars w Scale Mark - Pickle Jars for Sauerkraut, Sourdough Starter

Qianfenie Direct

$33.95

Five Star - 6022b_ - Star San - 32 Ounce - High Foaming Sanitizer

Bridgeview Beer and Wine Supply

$22.00 ($623.23 / Ounce)

AMZLMPKNTW Ball Lock Sample Faucet 30cm Reinforced Silicone Hose Secondary Fermentation Homebrew Kegging joyful

无为中南商贸有限公司

$39.22 ($39.22 / Count)

Brewer's Best Home Brew Beer Ingredient Kit - 5 Gallon (Mexican Cerveza)

Amazon.com

$53.24

1pc Hose Barb/MFL 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304(Gas MFL)

Guangshui Weilu You Trading Co., Ltd

$53.24

1pc Hose Barb/MFL 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304(Liquid Hose Barb)

yunchengshiyanhuqucuichendianzishangwuyouxiangongsi

$20.94

$29.99

The Brew Your Own Big Book of Clone Recipes: Featuring 300 Homebrew Recipes from Your Favorite Breweries

Amazon.com

$176.97

1pc Commercial Keg Manifold 2" Tri Clamp,Ball Lock Tapping Head,Pressure Gauge/Adjustable PRV for Kegging,Fermentation Control

hanhanbaihuoxiaoshoudian

$58.16

HUIZHUGS Brewing Equipment Keg Ball Lock Faucet 30cm Reinforced Silicone Hose Secondary Fermentation Homebrew Kegging Brewing Equipment

xiangshuizhenzhanglingfengshop

$10.99 ($31.16 / Ounce)

Hornindal Kveik Yeast for Homebrewing - Mead, Cider, Wine, Beer - 10g Packet - Saccharomyces Cerevisiae - Sold by Shadowhive.com

Shadowhive

Do a parti-gyle, using the later runnings for a much smaller beer. Basically, that beer is free.

Note:

Just use a little bit of your first runnings in the small beer too, so it won't taste thin. Using 20% of your small beer's total gravity (points) from first runnings is a good start.

Note:

Just use a little bit of your first runnings in the small beer too, so it won't taste thin. Using 20% of your small beer's total gravity (points) from first runnings is a good start.

Thanks! I'll adjust my corona mill to crush finer. I'm also going to have to attach a drill to that mill for those 27 pounds!That's possible. The spreadsheet tells you what you should get for lauter efficiency. You can then work backward (the spreadsheet will do this using goal seek) from your pre- or post-boil SG to get your conversion efficiency. Mash efficiency is conversion efficiency times lauter efficiency. So, it looks like your conversion efficiency is low, since it's easy to do a close to optimal batch sparge. The usual culprit with low conversion efficiency is a mash time too short to completely convert the grain at its crushed size. The easiest way to increase conversion efficiency is to crush finer, rather than mash longer (since with longer mashes, the enzyme activity is diminishing.)

Brew on

I've never made one before so I'll have to look up how to do it.Do a parti-gyle, using the later runnings for a much smaller beer. Basically, that beer is free.

Note:

Just use a little bit of your first runnings in the small beer too, so it won't taste thin. Using 20% of your total small beer's gravity (points) from first runnings is a good start.

I've found that these bigger beers finish kinda higher all by them selves so I tend to mash no higher then 152*. I also look at the ADF of the yeast and the lower that number the lower the temp of the mash or possibly a step mash. The ADF range is there because higher OG's cause stress and higher FG's as a result. I don't enjoy under attenuated beers so If this was my first big beer i would mash lower.

Would mashing this at 148F be too low?I've found that these bigger beers finish kinda higher all by them selves so I tend to mash no higher then 152*. I also look at the ADF of the yeast and the lower that number the lower the temp of the mash or possibly a step mash. The ADF range is there because higher OG's cause stress and higher FG's as a result. I don't enjoy under attenuated beers so If this was my first big beer i would mash lower.

Smellyglove

Well-Known Member

- Joined

- May 17, 2013

- Messages

- 2,807

- Reaction score

- 807

If you have the capacity to do so. You can look at your extract numbers from a "normal" OG beer, then use the same ratio of sparge and mash water in the big beer. This will give you a ballpark extract efficiency of the lower OG beer. You'd need to boil it accordingly longer though, with the effects of that.

For instace, if your "normal" beer calls for 50/50 mash/sparge water, duplicate the ratio in the big beer. This means you will use more sparge water than originally calculated.

For instace, if your "normal" beer calls for 50/50 mash/sparge water, duplicate the ratio in the big beer. This means you will use more sparge water than originally calculated.

You can certainly use more water to keep the grain weight to pre-boil volume ratio the same, to keep your lauter and mash efficiencies the same as for smaller beers. Let's see what that means as far as additional required boil-off:If you have the capacity to do so. You can look at your extract numbers from a "normal" OG beer, then use the same ratio of sparge and mash water in the big beer. This will give you a ballpark extract efficiency of the lower OG beer. You'd need to boil it accordingly longer though, with the effects of that.

For instace, if your "normal" beer calls for 50/50 mash/sparge water, duplicate the ratio in the big beer. This means you will use more sparge water than originally calculated.

For a 15 lb grain bill, 0.12 gal/lb grain absorption, 6.5 gal pre-boil, 5.5 gal post-boil, and single batch sparge if you get 100% conversion efficiency, then you get the following results:

Pre-boil SG: 1.065

Lauter Efficiency: 79.6%

Mash Efficiency: 79.6%

OG: 1.077

To get the same lauter and mash efficiencies with 27 lb of grain, you will need a pre-boil volume of 11.7 gal. Then to get the same 5.5 gal post-boil volume, you would need to boil-off 6.2 gal of water, vs. 1 gal boil-off for the 15 lb grain bill case. If you did that, your numbers would look like this:Lauter Efficiency: 79.6%

Mash Efficiency: 79.6%

OG: 1.077

Pre-boil SG: 1.065

Lauter Efficiency: 79.6%

Mash Efficiency: 79.6%

OG: 1.138

The above results came from the spreadsheet I linked in an earlier post.Lauter Efficiency: 79.6%

Mash Efficiency: 79.6%

OG: 1.138

Brew on

Similar threads

- Replies

- 24

- Views

- 3K

- Replies

- 3

- Views

- 949

- Replies

- 72

- Views

- 4K

Latest posts

-

-

-

-

-

-

-

Spike Conical Heater fails again--second in 3 years--ideas?

- Latest: Indian_villager

-

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)