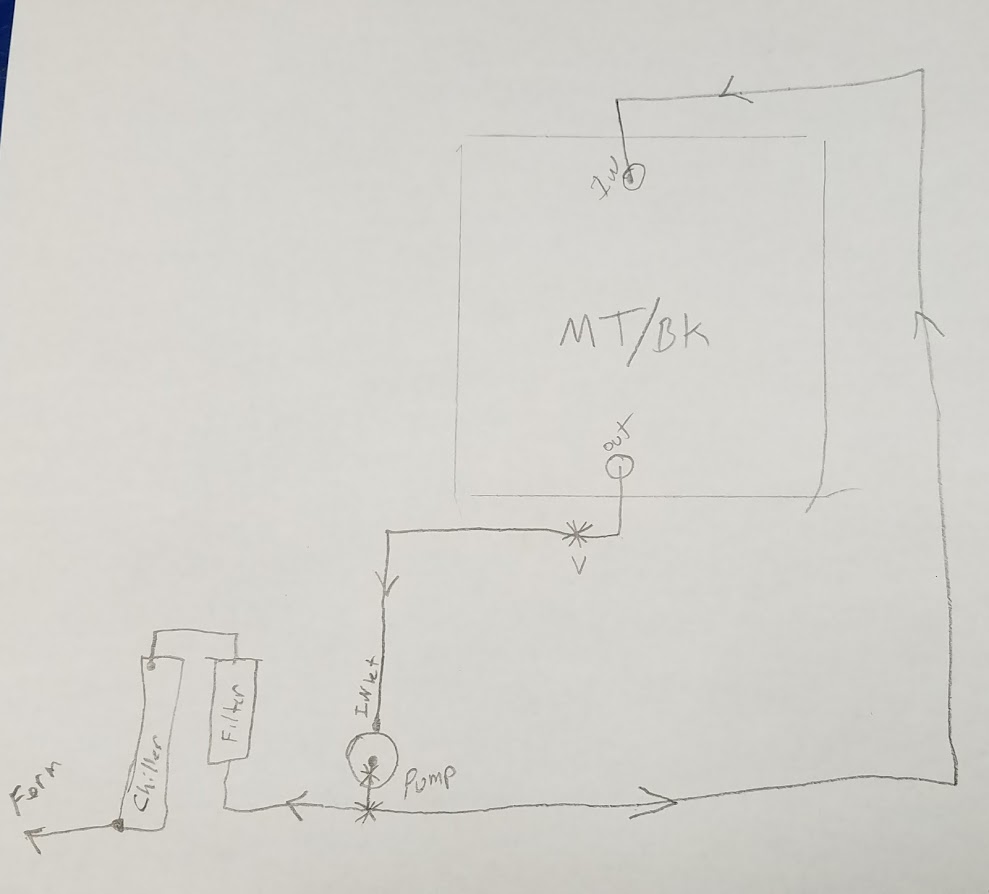

Im trying to setup my eBIAB rig, attached is pic below... sorry for crude drawing but i dont have neat skechup skills

my question is , I want to incorporate a 3 way valve at the outlet of the pump to switch easily between recirc and thru the chiller.

Which would work better? an L type? or T type?

I will still have a shut off at the kettle outlet. Can the L or T type be shut off totally? or is it always open to one port or the other?

thanks in advance...

my question is , I want to incorporate a 3 way valve at the outlet of the pump to switch easily between recirc and thru the chiller.

Which would work better? an L type? or T type?

I will still have a shut off at the kettle outlet. Can the L or T type be shut off totally? or is it always open to one port or the other?

thanks in advance...

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)