Silver_Is_Money

Larry Sayre, Developer of 'Mash Made Easy'

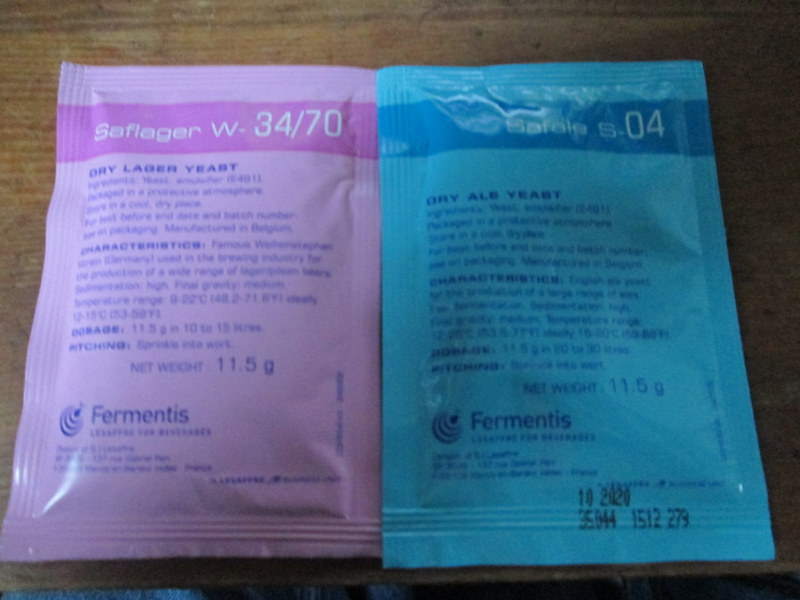

I listened to a podcast last night wherein a scientist working for Fermentis stated that their studies have found little to no difference between batches made with rehydrated yeast and identical batches made via pouring packs directly into the fermenter.

The article I linked below offers a brief summary of their findings:

https://fermentis.com/en/news-from-fermentis/technical-reviews/e2u-direct-pitching/

And here is a video discussing this, as well as advice to stop aerating (because it is detrimental) when using dry yeast:

The article I linked below offers a brief summary of their findings:

https://fermentis.com/en/news-from-fermentis/technical-reviews/e2u-direct-pitching/

And here is a video discussing this, as well as advice to stop aerating (because it is detrimental) when using dry yeast: