OK, got it. Seems to work OK. Don't you think you'll have to reload that can pretty often though?

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Dry Curing Sausage

- Thread starter passedpawn

- Start date

Help Support Homebrew Talk:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

rgauthier20420

Well-Known Member

- Joined

- Sep 20, 2012

- Messages

- 771

- Reaction score

- 70

I've read people that made a similar setup (using nicer containers for the pellets  ) that have smoker last 7-10 hours and some have it last 3-4 hours. From what I've read, it depends on how fast the air flows. I can get a small air control valve if I think it's going to fast and burns to quickly.

) that have smoker last 7-10 hours and some have it last 3-4 hours. From what I've read, it depends on how fast the air flows. I can get a small air control valve if I think it's going to fast and burns to quickly.

To be honest, either of these times are fine with me. But really, if I have to reload all I need to do is turn it upside down to empty and pop new pellets inside. It's that easy.

I'm getting some pellets this weekend, so maybe I'll do a test for 1 cup of pellets and see how long it smokes for.

For me, it's a successful build and I'm happy it only cost me $15 all in all

To be honest, either of these times are fine with me. But really, if I have to reload all I need to do is turn it upside down to empty and pop new pellets inside. It's that easy.

I'm getting some pellets this weekend, so maybe I'll do a test for 1 cup of pellets and see how long it smokes for.

For me, it's a successful build and I'm happy it only cost me $15 all in all

rgauthier20420

Well-Known Member

- Joined

- Sep 20, 2012

- Messages

- 771

- Reaction score

- 70

Sounds like you might be a bit of an OCD bastard like I.

Well sir it seems your right about me and OCD. After building the smoker, I'm already thinking of ways to redo it and make it a bit less ghetto. Damn you!

Nothin wrong with ghetto if it works. Well, so long as it doesnt blow up and maim someone.

10 days, no mold of any kind on the casing. Might still happen, but I was sure they'd be a mess and I'd be hitting them with vinegar by now. Maybe the CO2 from the fermenting beer in there is inhibiting the growth.

rgauthier20420

Well-Known Member

- Joined

- Sep 20, 2012

- Messages

- 771

- Reaction score

- 70

10 days, no mold of any kind on the casing. Might still happen, but I was sure they'd be a mess and I'd be hitting them with vinegar by now. Maybe the CO2 from the fermenting beer in there is inhibiting the growth.

Or you just did a good job in cleanliness

. I also think the completely enclosed environment helps inhibiting the mold growth, and of course the reduced temperatures. I didn't get any mold on mine to my surprise. Good to hear.

. I also think the completely enclosed environment helps inhibiting the mold growth, and of course the reduced temperatures. I didn't get any mold on mine to my surprise. Good to hear.How about some updated pictures? I'm sure they're looking completely different by now.

$10.99 ($31.16 / Ounce)

Hornindal Kveik Yeast for Homebrewing - Mead, Cider, Wine, Beer - 10g Packet - Saccharomyces Cerevisiae - Sold by Shadowhive.com

Shadowhive

$53.24

1pc Hose Barb/MFL 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304(Liquid Hose Barb)

yunchengshiyanhuqucuichendianzishangwuyouxiangongsi

$33.99 ($17.00 / Count)

$41.99 ($21.00 / Count)

2 Pack 1 Gallon Large Fermentation Jars with 3 Airlocks and 2 SCREW Lids(100% Airtight Heavy Duty Lid w Silicone) - Wide Mouth Glass Jars w Scale Mark - Pickle Jars for Sauerkraut, Sourdough Starter

Qianfenie Direct

$22.00 ($623.23 / Ounce)

AMZLMPKNTW Ball Lock Sample Faucet 30cm Reinforced Silicone Hose Secondary Fermentation Homebrew Kegging joyful

无为中南商贸有限公司

$7.79 ($7.79 / Count)

Craft A Brew - LalBrew Voss™ - Kveik Ale Yeast - For Craft Lagers - Ingredients for Home Brewing - Beer Making Supplies - (1 Pack)

Craft a Brew

$53.24

1pc Hose Barb/MFL 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304(Liquid Hose Barb)

Guangshui Weilu You Trading Co., Ltd

$20.94

$29.99

The Brew Your Own Big Book of Clone Recipes: Featuring 300 Homebrew Recipes from Your Favorite Breweries

Amazon.com

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)

$6.95 ($17.38 / Ounce)

$7.47 ($18.68 / Ounce)

Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]

Hobby Homebrew

$44.99

$49.95

Craft A Brew - Mead Making Kit – Reusable Make Your Own Mead Kit – Yields 1 Gallon of Mead

Craft a Brew

$176.97

1pc Commercial Keg Manifold 2" Tri Clamp,Ball Lock Tapping Head,Pressure Gauge/Adjustable PRV for Kegging,Fermentation Control

hanhanbaihuoxiaoshoudian

$58.16

HUIZHUGS Brewing Equipment Keg Ball Lock Faucet 30cm Reinforced Silicone Hose Secondary Fermentation Homebrew Kegging Brewing Equipment

xiangshuizhenzhanglingfengshop

Microscopist

Well-Known Member

- Joined

- Jun 6, 2014

- Messages

- 169

- Reaction score

- 33

Glad I'm not the only salami maker round here - my butcher constantly remarks at how surprised he is that I'm still alive.

I've stopped mincing my meat as my grinder doesn't give a coarse enough finish so I use a knife and fine chop with a few big chunks.

Last batch I experimented with adding gorgonzola to half of the mix, they bloomed blue after a month and then settled to powdery grey. Contrary to what I expected the cheese inoculated salamis ended up milder after six months hanging than the non cheesy. The deliberately molded bacon on the other hang was horribly earthy.

Made myself a smoker using an Ecosmoker burner ( runs on fine wooddust ) but so far it's only been used on fish and cheese. I give most things 24 hours in it.

Come winter when I get my next pig carcass I plan on training a time lapse camera on the hanging hams and salamis.

What's the purpose of freezing the meat beforehand?

I've stopped mincing my meat as my grinder doesn't give a coarse enough finish so I use a knife and fine chop with a few big chunks.

Last batch I experimented with adding gorgonzola to half of the mix, they bloomed blue after a month and then settled to powdery grey. Contrary to what I expected the cheese inoculated salamis ended up milder after six months hanging than the non cheesy. The deliberately molded bacon on the other hang was horribly earthy.

Made myself a smoker using an Ecosmoker burner ( runs on fine wooddust ) but so far it's only been used on fish and cheese. I give most things 24 hours in it.

Come winter when I get my next pig carcass I plan on training a time lapse camera on the hanging hams and salamis.

What's the purpose of freezing the meat beforehand?

rgauthier20420

Well-Known Member

- Joined

- Sep 20, 2012

- Messages

- 771

- Reaction score

- 70

Glad I'm not the only salami maker round here - my butcher constantly remarks at how surprised he is that I'm still alive.

I've stopped mincing my meat as my grinder doesn't give a coarse enough finish so I use a knife and fine chop with a few big chunks.

Last batch I experimented with adding gorgonzola to half of the mix, they bloomed blue after a month and then settled to powdery grey. Contrary to what I expected the cheese inoculated salamis ended up milder after six months hanging than the non cheesy. The deliberately molded bacon on the other hang was horribly earthy.

Made myself a smoker using an Ecosmoker burner ( runs on fine wooddust ) but so far it's only been used on fish and cheese. I give most things 24 hours in it.

Come winter when I get my next pig carcass I plan on training a time lapse camera on the hanging hams and salamis.

What's the purpose of freezing the meat beforehand?

It brings joy to my eyes to see more and more people posting about the cured/fermented meats. An interesting idea to put cheese inside of a salami. I wonder what would happen if some of the harder cheeses were used?

A slightly courser product isn't a bad thing at all. I've seen a recipe where you grind 1/2 the meat and then 1" cube the rest and stuff it with the fat like that. It's a beautiful finished product.

A reason for freezing the meat prior to beginning the process would be to kill of any Trichinosis. It's more for game meats than commercial, but it's just a precautionary step some take.

I'm going to propose a salami share! I'm picking up the cuts for my next batch this weekend and will be starting it during the week. I'll begin a thread there instead of jacking this one

I read about killing parasites in the meat with freezing, but I think the recommendation is to freeze for weeks. I froze just to get a good grind. If the meat gets warm, the fat will "smear" and you won't have nice marbled mix; it will look more like it was emulsified. Bad.

Because of the friction of the grinder and it's screw, you're adding plenty of heat anyway. So I find I can grind both the fat and the pork, even when completely frozen.

Because of the friction of the grinder and it's screw, you're adding plenty of heat anyway. So I find I can grind both the fat and the pork, even when completely frozen.

I've stopped mincing my meat as my grinder doesn't give a coarse enough finish so I use a knife and fine chop with a few big chunks.

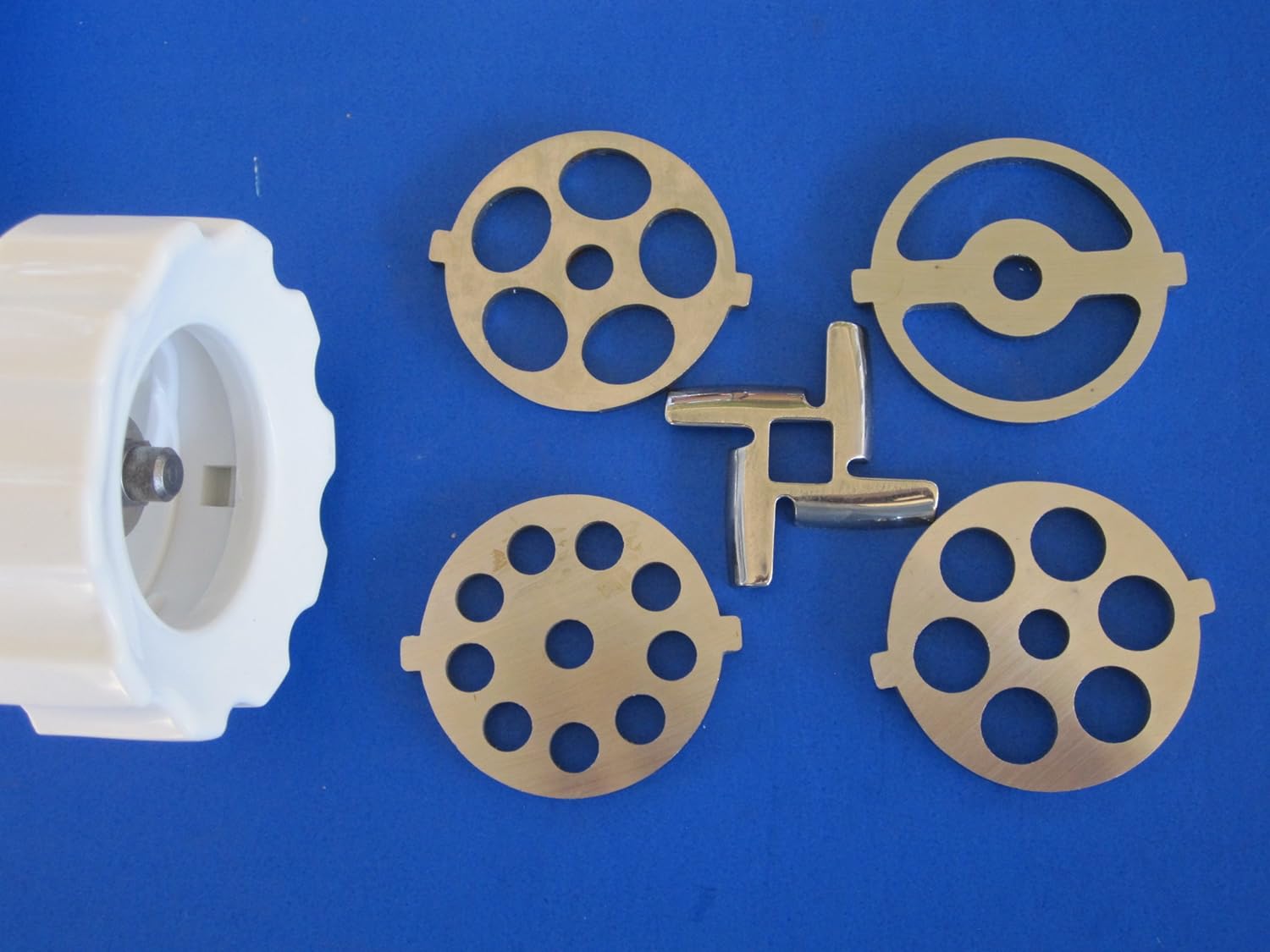

What do you think of these new dies for my Kitchenaid grinder attachment. Looks like you could get a much courser grinder with them.

johngaltsmotor

Well-Known Member

Grinding meat and fat completely frozen depends on your equipment. Mine stays cold enough that when you grind frozen, even with coarse plates (1/2") you end up shaving off meat and end up a lot finer than called for. I par-freeze the fat for 2 hours and the meat for an hour. Just like brewing: whatever works best for your equipment is what you need to do.

To kill thicinae it takes extreme cold for an extended period (IIRC <0F for 3 weeks). I tend to buy my pork butts as I have room in the deep freeze and let them sit for a month until I get time to turn them into sausage anyway so it doesn't matter if I make dry cured or smoked varieties.

To kill thicinae it takes extreme cold for an extended period (IIRC <0F for 3 weeks). I tend to buy my pork butts as I have room in the deep freeze and let them sit for a month until I get time to turn them into sausage anyway so it doesn't matter if I make dry cured or smoked varieties.

Couple of interesting links for the totally-obsessed.

BTW, I'm getting about 1% a day now in loss of weight. Math is easy now. I can almost taste it. I'll get a new pic this weekend of the snausages (focus!).

BTW, I'm getting about 1% a day now in loss of weight. Math is easy now. I can almost taste it. I'll get a new pic this weekend of the snausages (focus!).

They are done - 68% of original weight. You can see in the pic that there were some spots of white fuzz on them, which apparently is normal (my wife isn't buying that, though). I'm pulling them out of the fridge - and into my mouth. If you don't hear from me again, I very much enjoyed our time together. Cheers.

I smelled it before I ate it and was surprised that it smelled exactly like salami. I've already eaten most of the first link. It passes muster. When I make it again, I'll probably go drier, to 60%. It's not soft, but I'd like it to be firmer. Flavor is perfect.

Another note: don't let the links touch each other while drying. Where they were touching there was much more mold.

I put a few of the salami back into the curing chamber to let them dry out more. Just want to see what 50-60% of original weight is like.

rgauthier20420

Well-Known Member

- Joined

- Sep 20, 2012

- Messages

- 771

- Reaction score

- 70

They look great! Very nice color and it doesn't look like you've got any dry rims issues. Very nice separation of the meat and fat. Need my address to send some?

They look great! Very nice color and it doesn't look like you've got any dry rims issues. Very nice separation of the meat and fat. Need my address to send some?

If you're serious, PM me. I'll be vacuum-packing these guys tonight, I could send one to you for quality inspection.

rgauthier20420

Well-Known Member

- Joined

- Sep 20, 2012

- Messages

- 771

- Reaction score

- 70

If you're serious, PM me. I'll be vacuum-packing these guys tonight, I could send one to you for quality inspection.

PM sent

Now that you've proved this successful with your current equipment....what's next?

PM sent

Now that you've proved this successful with your current equipment....what's next?

I have a hog middle that I'd like to stuff and make a true 3" salami. I'm going to be brewing a new lager next weekend, so I'll probably go ahead and make another salami. I can't dry anything that takes more than about a month since I use my fermenting chamber for drying, and the I have to synchronize my drying with a fermenting lager.

I might make a chorizo instead, not really sure yet. But it will be something stuffed in the 3" casing.

vagabondat02

Well-Known Member

Looking good! The mold you had growing looks like one of the healthy, tasty ones. As long as it doesn't get too fuzzy, or start turning blue or green, it will only improve the flavor of your salami. If it does start going crazy on you, just wash off the casing and wipe it down with diluted vinegar. Congratulations, and welcome to the wild, wonderful world of fermented meat!

dinnerstick

Well-Known Member

Hi salami freaks. I just made my first batch yesterday. Simple recipe; pork shoulder, fatback, spices, salt, cure #2, and a standard culture mix. Adapted from modernist cuisine. Half the batch got garlic, black pepper, toasted ground fennel seeds, the second half got garlic, szechwan peppers, coriander seed, pimenton (smoked paprika), chili flakes; powdered. Medium hog casing. We fried up the bits of leftover filling that didn't make it into the casing as little patties, they were both unbelievably good.

Now. It's my first go at this. I understand the theory behind fermentation time, drying time, temperature, relative humidity, but I can't spare a fridge as a humidity chamber. I have had them them hanging in my basement overnight, currently at 19 degrees C and around 62% RH. The recipe says to start them warm (18-20C) to ferment, before drying cooler (~12C) at ~75% RH. I'm simply curious as to other people's experiences with similar size sausages and drying without a dedicated chamber. I will move them to a cooler part of the cellar, not sure about the humidity there. But am I going to dry the outside way too fast and leave the insides manky? Should I try to get a simple humidity tent going? Any experiences or ideas appreciated. I should say, I suddenly feel like a novice brewer who is only realizing that yeast health and ferm temp are the important variables, even though I read it in a book before starting in...

Also, I don't have a lot of free space! Thanks!

Now. It's my first go at this. I understand the theory behind fermentation time, drying time, temperature, relative humidity, but I can't spare a fridge as a humidity chamber. I have had them them hanging in my basement overnight, currently at 19 degrees C and around 62% RH. The recipe says to start them warm (18-20C) to ferment, before drying cooler (~12C) at ~75% RH. I'm simply curious as to other people's experiences with similar size sausages and drying without a dedicated chamber. I will move them to a cooler part of the cellar, not sure about the humidity there. But am I going to dry the outside way too fast and leave the insides manky? Should I try to get a simple humidity tent going? Any experiences or ideas appreciated. I should say, I suddenly feel like a novice brewer who is only realizing that yeast health and ferm temp are the important variables, even though I read it in a book before starting in...

Also, I don't have a lot of free space! Thanks!

Hi salami freaks. I just made my first batch yesterday. Simple recipe; pork shoulder, fatback, spices, salt, cure #2, and a standard culture mix. Adapted from modernist cuisine. Half the batch got garlic, black pepper, toasted ground fennel seeds, the second half got garlic, szechwan peppers, coriander seed, pimenton (smoked paprika), chili flakes; powdered. Medium hog casing. We fried up the bits of leftover filling that didn't make it into the casing as little patties, they were both unbelievably good.

Now. It's my first go at this. I understand the theory behind fermentation time, drying time, temperature, relative humidity, but I can't spare a fridge as a humidity chamber. I have had them them hanging in my basement overnight, currently at 19 degrees C and around 62% RH. The recipe says to start them warm (18-20C) to ferment, before drying cooler (~12C) at ~75% RH. I'm simply curious as to other people's experiences with similar size sausages and drying without a dedicated chamber. I will move them to a cooler part of the cellar, not sure about the humidity there. But am I going to dry the outside way too fast and leave the insides manky? Should I try to get a simple humidity tent going? Any experiences or ideas appreciated. I should say, I suddenly feel like a novice brewer who is only realizing that yeast health and ferm temp are the important variables, even though I read it in a book before starting in...

Also, I don't have a lot of free space! Thanks!

Sounds like you know EXACTLY what the dangers are. Low RH and the inside will stay spongy / nasty. To keep the RH up, hang them in a large plastic box or bag.

You definitely want the warm start to get the fermentation up and the pH down.

Keep an eye on mold growth. Brush with vinegar. Some mold will eat away at the casing: you don't want that.

Weigh one of your links, and keep weighing it over time to know how much drying you've accomplished.

I meant to make a bunch over the winter but got busy. Good luck with yours. Let's see some pics soon.

dinnerstick

Well-Known Member

Sounds like you know EXACTLY what the dangers are. Low RH and the inside will stay spongy / nasty. To keep the RH up, hang them in a large plastic box or bag.

You definitely want the warm start to get the fermentation up and the pH down.

Keep an eye on mold growth. Brush with vinegar. Some mold will eat away at the casing: you don't want that.

Weigh one of your links, and keep weighing it over time to know how much drying you've accomplished.

I meant to make a bunch over the winter but got busy. Good luck with yours. Let's see some pics soon.

Thanks for the tips. I'll try to knock up a humidity tent without resorting to hanging them in my currently empty plastic conical....!

I am indeed monitoring the weight. I'm sure i'll post back pretty soon. Here they are after half a day hanging. The dark ones are fennel, red ones are the bonkers other ones.

dinnerstick

Well-Known Member

I made a little low tech (no tech?) humidity chamber from an old plastic crate. It's a pan of water, a thermometer and my old dial hygrometer. The front is just a plastic bag cut open and draped over loosely. The RH shot up from 63 to ~77% immediately (despite what the dial says in the pic). I'll keep an eye on it like this for a day or so and ventilate periodically. Meanwhile the salami got a bit of white mold, and I brushed them with vinegar. As i brushed, the mold really looked like the white mold coating on various salami/fuet. I don't know if that mold was in the mixed culture I used, but I was eating a white coated fuet at the same time and intentionally not washing my hands...?

(and for those not familiar that's a plastic single-use keykeg next to the box, we get our beer in them where I contract brew. Weird things, it's a bag of beer inside a plastic shell.)

(and for those not familiar that's a plastic single-use keykeg next to the box, we get our beer in them where I contract brew. Weird things, it's a bag of beer inside a plastic shell.)

dinnerstick

Well-Known Member

1 week update: Holding around 80% RH and 19 deg C, they are looking good. Haven't weighed them again but they are shrinking slowly. They have sporadic white mold, powdery and fluffy. If this the good stuff?? No black or green mold to be seen. The smell is gooooood!

Looking good! Yea, that looks like the good mold. Man I wish I had some of my own right now. Maybe later this week.

dinnerstick

Well-Known Member

update: 3 weeks in. the sausages have lost on average 34% of their 'original' (which was 1 day after hanging) weight, with some variation from one to the other. also the white mold is variable, but definitely does not like to grow over the fatty bits. they look good, they feel good, and they smell great. no sign of anything growing on them other than the white stuff, which, when you get it on your hand, smells like the white mold on salami. my partner in crime is building a little computer controlled temp/humidity chamber with an arduino, so we can finish them at low temp, but the parts are taking a long tie to arrive, so they are sitting at 75% RH and ~19c.

Last edited:

dinnerstick

Well-Known Member

first taste! and it was good. both are not quite spot on with the texture, the meat needs to be in bigger chunks and the fat smaller, but for a first go i ain't complaining! both moist in the middle, but not soggy or mushy, pleasant texture, could be a bit drier but probably not attainable without a drying cabinet build.... the fennel/pepper one is firmer than the chili/szechuwan/pimenton/coriander one. the latter is spicy but more chili than szechuwan, and really tasty. garlic is mellow, spice builds but is in check. the fennel one is amazing. punchy anise flavor backed up by the black pepper. wow, planning next batch.

Similar threads

- Replies

- 0

- Views

- 221

- Replies

- 7

- Views

- 2K

- Replies

- 57

- Views

- 4K