I'm just starting to understand my newly assembled Clawhammer 10 gallon electric BIAB system, and could use some insight. It's unclear to me when (and how long) I should run the pump during the mash &/or the boil for an all-grain brew. The pump is set up to pump the wort from the bottom of the Clawhammer kettle to the top connection on the lid, which is a spray valve inside the lid. Should the pump run all the time during the mash? Or only at certain times? What about during the boil? I'm guessing that since this is a BIAB-type system, I should be using the full amount of water pre-mash? The system didn't really come with enough specific information about this, so I hope to get some learning in...!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Do I run pump during mash/boil using Clawhammer BIAB system?

- Thread starter diverjim

- Start date

Help Support Homebrew Talk:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

Happy Tails Brewing

Active Member

If I had your system I would do full volume. Turn the pump on as you heat to strike temp. Then turn off and stir in your grains. Give the grains 5 – 10 Min and then turn the pump on for the rest of the mash. Once mash is complete Turn off the pump and lift the basket. Pump will be off for the boil. If you plan to use your pump to transfer to your fermentation vessel, I would turn on the pump for the last 10 – 15 min of your boil to sanitize everything.

Many brewers use Clawhammers’ system. Clawhammer themselves have an extensive YouTube channel, and you will be able to find several other brewers on YouTube using the system.

Watch a couple videos and enjoy, I understand it’s a great system.

Many brewers use Clawhammers’ system. Clawhammer themselves have an extensive YouTube channel, and you will be able to find several other brewers on YouTube using the system.

Watch a couple videos and enjoy, I understand it’s a great system.

Recirculate during the mash, not during the boil.

To be extremely blunt about it, spraying the recirculating mash liquor through a nozzle is a bad design from an oxygen exposure perspective. That would be the first modification I'd be making to that system so the recirc more gently delivers the liquid to the surface of the mash.

To be extremely blunt about it, spraying the recirculating mash liquor through a nozzle is a bad design from an oxygen exposure perspective. That would be the first modification I'd be making to that system so the recirc more gently delivers the liquid to the surface of the mash.

Thanks for the insights! I have watched a number of videos on YT about using the Clawhammer system, but none of them have gone into enough detail about specific timings. I do use the pump to transfer the wort into the fermenter, mostly because I don't know how else I would get the bulk of the remaining wort from within the hoses/pump/plate chiller into the fermenter. It seems sort of tricky to get all that liquid out of the system without running the pump dry.If I had your system I would do full volume. Turn the pump on as you heat to strike temp. Then turn off and stir in your grains. Give the grains 5 – 10 Min and then turn the pump on for the rest of the mash. Once mash is complete Turn off the pump and lift the basket. Pump will be off for the boil. If you plan to use your pump to transfer to your fermentation vessel, I would turn on the pump for the last 10 – 15 min of your boil to sanitize everything.

Many brewers use Clawhammers’ system. Clawhammer themselves have an extensive YouTube channel, and you will be able to find several other brewers on YouTube using the system.

Watch a couple videos and enjoy, I understand it’s a great system.

I'm not knowledgeable enough about oxygen exposure prior to the boil to know what the effects are. What would you suggest as a replacement to the sprayer valve that would be better?Recirculate during the mash, not during the boil.

To be extremely blunt about it, spraying the recirculating mash liquor through a nozzle is a bad design from an oxygen exposure perspective. That would be the first modification I'd be making to that system so the recirc more gently delivers the liquid to the surface of the mash.

Thanks for your help!

Snuffy

He ain't scared.

- Joined

- Nov 5, 2019

- Messages

- 1,937

- Reaction score

- 3,099

I've seen the threads about protecting the mash from oxygen. Folks actually devising caps for the mash to keep out air. And then you have the instruction to aerate or actually inject oxygen into the wort before pitching - particularly for hi-grav brews w/ wet yeast. If the yeast need oxygen to begin with, what purpose would it serve to avoid it before the boil? And doesn't the boil remove oxygen as well? I've asked similar questions of the LODO folks before and they can be kind of touchy on the subject.Recirculate during the mash, not during the boil.

To be extremely blunt about it, spraying the recirculating mash liquor through a nozzle is a bad design from an oxygen exposure perspective. That would be the first modification I'd be making to that system so the recirc more gently delivers the liquid to the surface of the mash.

$176.97

1pc Commercial Keg Manifold 2" Tri Clamp,Ball Lock Tapping Head,Pressure Gauge/Adjustable PRV for Kegging,Fermentation Control

hanhanbaihuoxiaoshoudian

$20.94

$29.99

The Brew Your Own Big Book of Clone Recipes: Featuring 300 Homebrew Recipes from Your Favorite Breweries

Amazon.com

$33.99 ($17.00 / Count)

$41.99 ($21.00 / Count)

2 Pack 1 Gallon Large Fermentation Jars with 3 Airlocks and 2 SCREW Lids(100% Airtight Heavy Duty Lid w Silicone) - Wide Mouth Glass Jars w Scale Mark - Pickle Jars for Sauerkraut, Sourdough Starter

Qianfenie Direct

$10.99 ($31.16 / Ounce)

Hornindal Kveik Yeast for Homebrewing - Mead, Cider, Wine, Beer - 10g Packet - Saccharomyces Cerevisiae - Sold by Shadowhive.com

Shadowhive

$7.79 ($7.79 / Count)

Craft A Brew - LalBrew Voss™ - Kveik Ale Yeast - For Craft Lagers - Ingredients for Home Brewing - Beer Making Supplies - (1 Pack)

Craft a Brew

$58.16

HUIZHUGS Brewing Equipment Keg Ball Lock Faucet 30cm Reinforced Silicone Hose Secondary Fermentation Homebrew Kegging Brewing Equipment

xiangshuizhenzhanglingfengshop

$22.00 ($623.23 / Ounce)

AMZLMPKNTW Ball Lock Sample Faucet 30cm Reinforced Silicone Hose Secondary Fermentation Homebrew Kegging joyful

无为中南商贸有限公司

$53.24

1pc Hose Barb/MFL 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304(Gas MFL)

yunchengshiyanhuqucuichendianzishangwuyouxiangongsi

$39.22 ($39.22 / Count)

Brewer's Best Home Brew Beer Ingredient Kit - 5 Gallon (Mexican Cerveza)

Amazon.com

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)

$6.95 ($17.38 / Ounce)

$7.47 ($18.68 / Ounce)

Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]

Hobby Homebrew

$53.24

1pc Hose Barb/MFL 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304(Gas MFL)

Guangshui Weilu You Trading Co., Ltd

Happy Tails Brewing

Active Member

It pretty easy. Run the pump as you heat the water before adding grains. This will mix the water to ensure the temp the prob is reading is the temp of all the water. Next add your grains and give a good stir. This will ensure all the grains are wet and you don't have clumps. Then run the pump during mash. This will help with efficiency and keeping your temp on target. I normally do a 60 min mash some do 30 and others do 90. It’s about time spent against sugar extraction. I do take a gravity reading every 15 min. I see a big jump in 15 another sizable at 30 and just a little at 45, and next to nothing at 60. If I see a bigger jump at 60, I have extended to 75 to ensure my conversion was done. Once you are happy your mash is done pull your basket, let it drain and start heating up to a boil. The basket can hang as long as you want, but I would remove it before you get too close to a boil, you want the top clear in case things come close to boiling over. Again I boil for 60 min, but other do 30, 90, or 120. It's just how much time you want to spend, and how much hop and mallard reaction you want. 60 and 60 is old school and a safe place to start. Given what you said about transferring to your fermenter and using a plate chiller, I would run the pump and the chiller for the last 10 – 15 min of the boil this will heat and kill anything that might be hiding in these. Once your boil is complete you can turn the water on to the chiller, and when you are happy with the output temp from the chiller transfer to your fermenter.Thanks for the insights! I have watched a number of videos on YT about using the Clawhammer system, but none of them have gone into enough detail about specific timings. I do use the pump to transfer the wort into the fermenter, mostly because I don't know how else I would get the bulk of the remaining wort from within the hoses/pump/plate chiller into the fermenter. It seems sort of tricky to get all that liquid out of the system without running the pump dry.

As for oxygen exposure I would run as is to get a feel for the system and then figure out what you want to do. I know Bobby sells locline that will allow you to set and any level. I currently use a hose with a float to be at the top of my wort. You can see how the beer turns out, and upgrade as you go, but Bobby will have better advice then me. Bobby knows what he is doing, so his advice has worthwhile to keep in mind.

I brew on a different system, but the steps are the same. Everything above is what I do except for I sparge, but I wouldn't do that with what you have unless you cannot fit the full volume in the kettle to start.

You should have no issues making good beer. You may make a few mistakes along the way we all have and still do, but have a couple of brews you will know how, and what you want to do to enjoy the process.

You should

In general, chemical reactions happen faster at higher temperatures than lower temperatures, and oxidation is a chemical reaction. Typically, reactions in organic chemistry happen about twice as fast for each 10°C (18°F) of increased temperature. Thus oxidation at 70°C (mash temp) will happen about 2^5 = 32 times faster than at 20°C (pitch temp). So, 1 minute at mash temps will give you about the same level of oxidation as 30 minutes at pitch temps.

IIRC, the LoDO brewers recommend pitching an active starter prior to oxygenating the wort, so that the yeast can begin immediately consuming the O2 so they get what they need for propagation, and the DO in the wort drops more quickly than if you oxygenate first, or pitch yeast that are going to lag for a while before propagating.

Brew on

I've seen the threads about protecting the mash from oxygen. Folks actually devising caps for the mash to keep out air. And then you have the instruction to aerate or actually inject oxygen into the wort before pitching - particularly for hi-grav brews w/ wet yeast. If the yeast need oxygen to begin with, what purpose would it serve to avoid it before the boil? And doesn't the boil remove oxygen as well? I've asked similar questions of the LODO folks before and they can be kind of touchy on the subject.

In general, chemical reactions happen faster at higher temperatures than lower temperatures, and oxidation is a chemical reaction. Typically, reactions in organic chemistry happen about twice as fast for each 10°C (18°F) of increased temperature. Thus oxidation at 70°C (mash temp) will happen about 2^5 = 32 times faster than at 20°C (pitch temp). So, 1 minute at mash temps will give you about the same level of oxidation as 30 minutes at pitch temps.

IIRC, the LoDO brewers recommend pitching an active starter prior to oxygenating the wort, so that the yeast can begin immediately consuming the O2 so they get what they need for propagation, and the DO in the wort drops more quickly than if you oxygenate first, or pitch yeast that are going to lag for a while before propagating.

Brew on

Snuffy

He ain't scared.

- Joined

- Nov 5, 2019

- Messages

- 1,937

- Reaction score

- 3,099

That makes perfect sense. So your pre-boil oxygen avoidance gives you time to delay the introduction of oxygen until the yeast are ready to mop it up. Which leaves less time for the reactions to oxidize later. Thanks for that.You should

In general, chemical reactions happen faster at higher temperatures than lower temperatures, and oxidation is a chemical reaction. Typically, reactions in organic chemistry happen about twice as fast for each 10°C (18°F) of increased temperature. Thus oxidation at 70°C (mash temp) will happen about 2^5 = 32 times faster than at 20°C (pitch temp). So, 1 minute at mash temps will give you about the same level of oxidation as 30 minutes at pitch temps.

IIRC, the LoDO brewers recommend pitching an active starter prior to oxygenating the wort, so that the yeast can begin immediately consuming the O2 so they get what they need for propagation, and the DO in the wort drops more quickly than if you oxygenate first, or pitch yeast that are going to lag for a while before propagating.

Brew on

That makes perfect sense. So your pre-boil oxygen avoidance gives you time to delay the introduction of oxygen until the yeast are ready to mop it up. Which leaves less time for the reactions to oxidize later. Thanks for that.

It's been explained well already, but just to be extra verbose; oxygen isn't inert anywhere at any time. It's extremely electron hungry, aka reactive with every other element. People tend to shrug off oxygen damage to their beer at all different phases due to the one short period of time where it provides yeast benefit (at actual pitching time). The oxygen doesn't float around intact waiting for the yeast to eventually use it. In fact, we'd prefer the yeast not need it so we could keep oxygen away from the beer 100% of the time rather than 99% but we can't fight biology.

That makes perfect sense. So your pre-boil oxygen avoidance gives you time to delay the introduction of oxygen until the yeast are ready to mop it up.

Kind of. The problem with pre-boil oxygen is that it does absolutely nothing beneficial, in fact, all it can do is oxidize the wort. That's why LODO brewers add ascorbic acid to the mash, to provide extra substrate for ascorbate oxidase to scavenge oxygen by combining it with ascorbate. The second your wort comes to a boil, any dissolved oxygen is driven off within 5 minutes anyway. LODO brewers use this principle to their advantage, pre-boiling and chilling the water prior to mashing in, to remove oxygen.

It's been explained well already, but just to be extra verbose; oxygen isn't inert anywhere at any time. It's extremely electron hungry

Technically oxygen is nucleophilic, not electrophilic. Oxidation doesn't just refer to the act of oxygen itself reacting with things but any chemical reaction where electrons are transferred (lost) by an oxidizing agent (like oxygen).

There are a few ways, very economical to moderately so..I'm not knowledgeable enough about oxygen exposure prior to the boil to know what the effects are. What would you suggest as a replacement to the sprayer valve that would be better?

Thanks for your help!

You could remove the sprayer fitting and just feed a piece of silicone hose down to the surface of the mash and put a barbed elbow fitting at the bottom so the recirculating liquid doesn't drill down into the mash. Set the height just by how far down you insert the silicone tubing through the hole. Almost free, 99% improvement in oxygen avoidance.

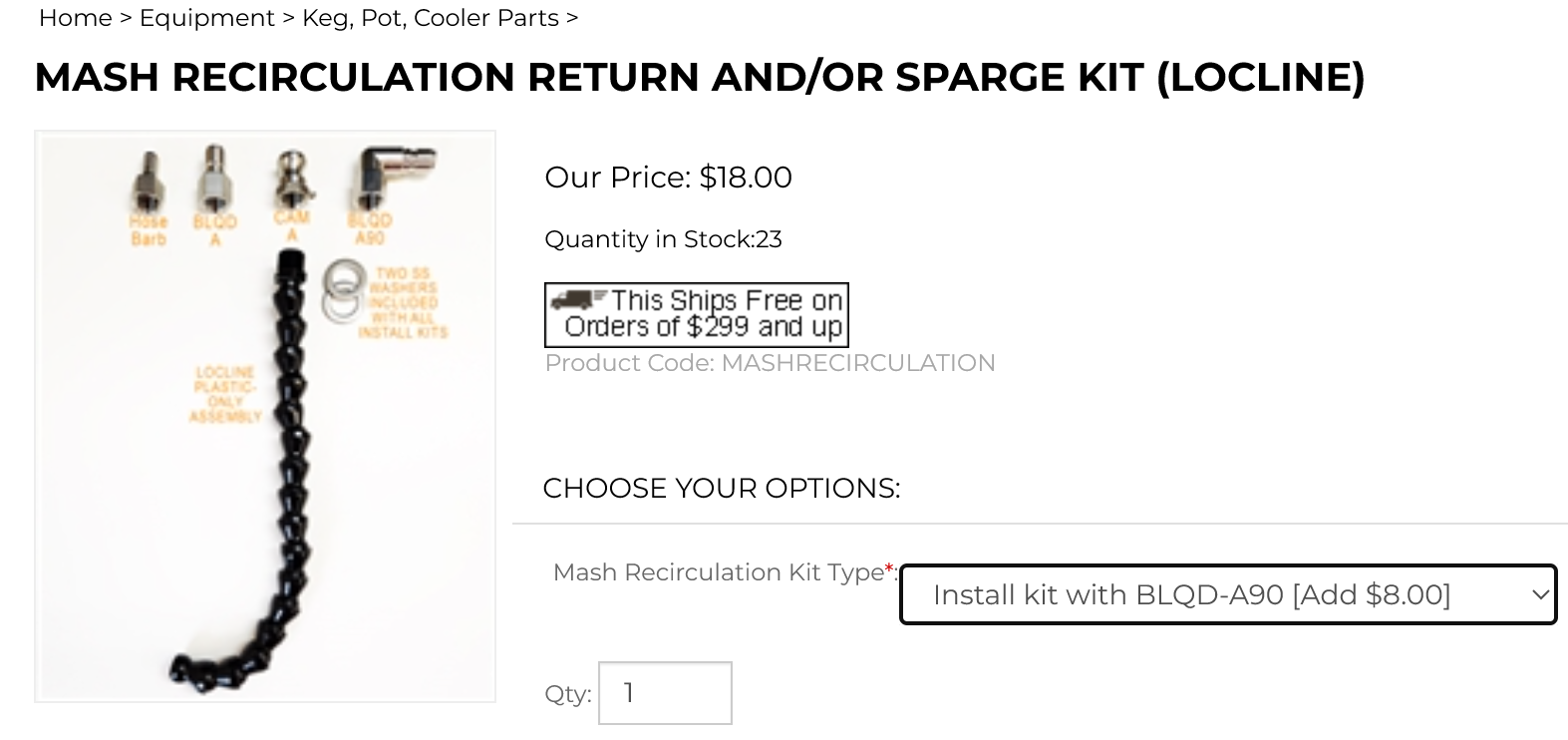

The slightly slicker way is locline which is like a bendy straw that stays put where you put it. Height adjust to the grain bill and position the outflow however you want (just above the grain in a way that makes the liquid swirl around the kettle).

The option that has the BLQD-A90 installs like this with the lid being between the two SS washers and then your hose doesn't need to make a major bend and kink.

Similar threads

- Replies

- 27

- Views

- 3K

- Replies

- 22

- Views

- 2K

Colorado

Nano Homebrew System (10-15 Gallons)

- Replies

- 0

- Views

- 2K

- Replies

- 24

- Views

- 3K