Are the taps running yet? If so, can we get a rundown on how they are set up?

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

DIY Walk In Cooler Build

- Thread starter Irrenarzt

- Start date

Help Support Homebrew Talk:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

The taps do work but I am not completely set up on the gas side manifold. Since I've been mainly drinking bottles, I've been slow at finishing up the gas plumbing. I will post up once I get that done.

Spookgolds

Well-Known Member

I just spent the last few hours reading all of this. Awesome. Wish I had room to put a walk in.

cpl-america

Well-Known Member

That's life in the southwest. It was a perfect day in the 60's today.

Ironically, here in the u.k. Where we had so much snow last year, it too has been a breezy 60. Not a flake All winter. ::knock on wood::

Sent from my GT-N5110 using Home Brew mobile app

TheDarkChemist

Well-Known Member

Considering doing something like this but smaller in a brewshed, curious what your total price came out to, apologies if I missed it, just read your whole thread

Awesomeness.

Awesomeness.

I never added up all the receipts but I'm going to say it was around 5K with everything but the beer inside. And there is a LOT of beer in there now.

I'm very close to having the gas lines all done. I plan to post up pics of the draft system once it's all working, which will be soon.

Edit: All 5 taps are now flowing. Ghettogyle Greg helped out with the gas lines. There is one more tweak, then I can take pics.

I'm very close to having the gas lines all done. I plan to post up pics of the draft system once it's all working, which will be soon.

Edit: All 5 taps are now flowing. Ghettogyle Greg helped out with the gas lines. There is one more tweak, then I can take pics.

$22.00 ($623.23 / Ounce)

AMZLMPKNTW Ball Lock Sample Faucet 30cm Reinforced Silicone Hose Secondary Fermentation Homebrew Kegging joyful

无为中南商贸有限公司

$10.99 ($31.16 / Ounce)

Hornindal Kveik Yeast for Homebrewing - Mead, Cider, Wine, Beer - 10g Packet - Saccharomyces Cerevisiae - Sold by Shadowhive.com

Shadowhive

$7.79 ($7.79 / Count)

Craft A Brew - LalBrew Voss™ - Kveik Ale Yeast - For Craft Lagers - Ingredients for Home Brewing - Beer Making Supplies - (1 Pack)

Craft a Brew

$53.24

1pc Hose Barb/MFL 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304(Gas MFL)

Guangshui Weilu You Trading Co., Ltd

$479.00

$559.00

EdgeStar KC1000SS Craft Brew Kegerator for 1/6 Barrel and Cornelius Kegs

Amazon.com

$28.98

Five Star - 6022b_ - Star San - 32 Ounce - High Foaming Sanitizer

Great Fermentations of Indiana

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)

$6.95 ($17.38 / Ounce)

$7.47 ($18.68 / Ounce)

Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]

Hobby Homebrew

$44.99

$49.95

Craft A Brew - Mead Making Kit – Reusable Make Your Own Mead Kit – Yields 1 Gallon of Mead

Craft a Brew

$58.16

HUIZHUGS Brewing Equipment Keg Ball Lock Faucet 30cm Reinforced Silicone Hose Secondary Fermentation Homebrew Kegging Brewing Equipment

xiangshuizhenzhanglingfengshop

$159.99 ($26.66 / Count)

3M High Flow Series System BREW120-MS, 5616001, For Brewed Coffee and Hot Tea, Valve-in-Head Design

SpaceCityProviders

$53.24

1pc Hose Barb/MFL 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304(Liquid Hose Barb)

yunchengshiyanhuqucuichendianzishangwuyouxiangongsi

$176.97

1pc Commercial Keg Manifold 2" Tri Clamp,Ball Lock Tapping Head,Pressure Gauge/Adjustable PRV for Kegging,Fermentation Control

hanhanbaihuoxiaoshoudian

$719.00

$799.00

EdgeStar KC2000TWIN Full Size Dual Tap Kegerator & Draft Beer Dispenser - Black

Amazon.com

$33.99 ($17.00 / Count)

$41.99 ($21.00 / Count)

2 Pack 1 Gallon Large Fermentation Jars with 3 Airlocks and 2 SCREW Lids(100% Airtight Heavy Duty Lid w Silicone) - Wide Mouth Glass Jars w Scale Mark - Pickle Jars for Sauerkraut, Sourdough Starter

Qianfenie Direct

$76.92 ($2,179.04 / Ounce)

Brewing accessories 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304 Brewing accessories(Gas Hose Barb)

chuhanhandianzishangwu

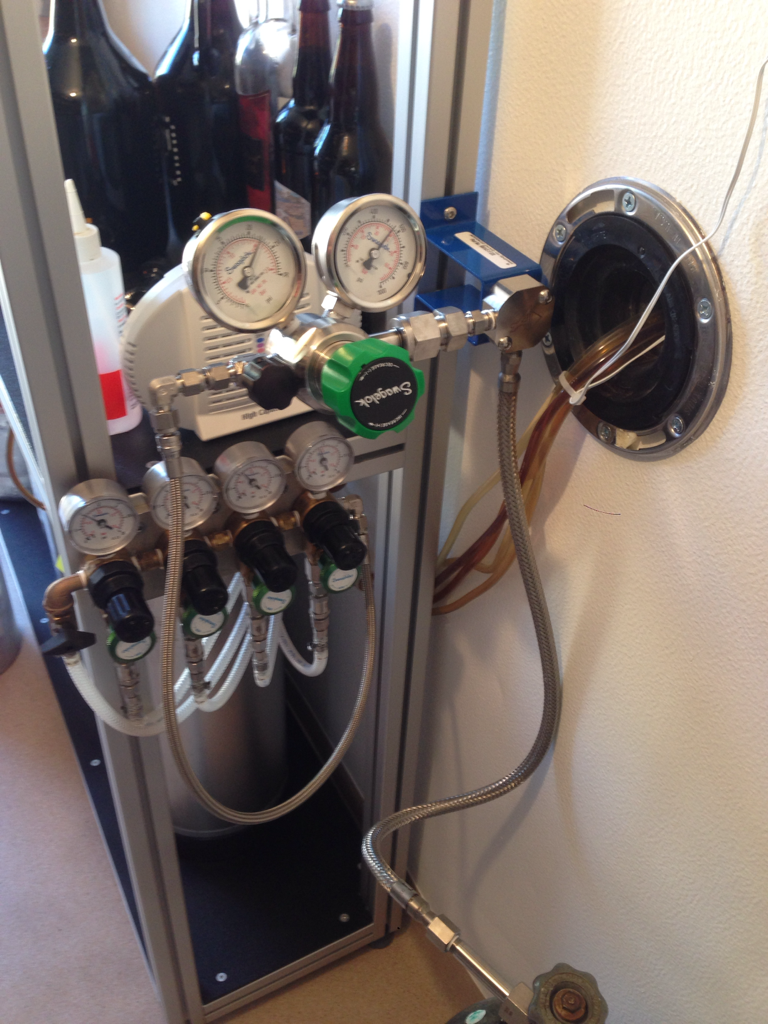

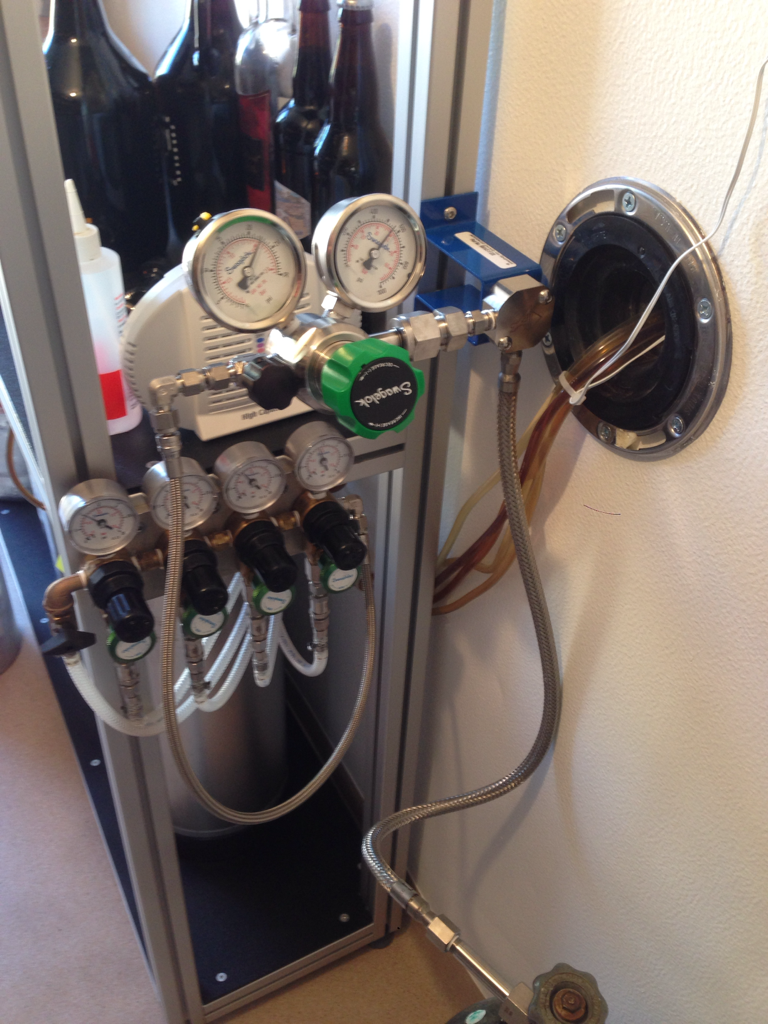

Quick and dirty post on the taps as they are all flowing.

Taps and 32" 1080i TV with Raspberry Pints listing the beers:

Pretty full up on bottles these days:

I mounted the regulator to the frame itself and pigtailed it to the tank so I can essentially hot swap tanks out...

Right now I have 4 homebrews in cornies and my Beer Camp beer in a half barrel. I was too lazy to move the half barrel to get the gas line behind it so I'm running a second tank of CO2 into the sanke key to push that beer. Lazy I know. I promise this isn't a permanent thing.

My apologies for the blurry pics. My phone seems to be getting old, or it could be me.

Taps and 32" 1080i TV with Raspberry Pints listing the beers:

Pretty full up on bottles these days:

I mounted the regulator to the frame itself and pigtailed it to the tank so I can essentially hot swap tanks out...

Right now I have 4 homebrews in cornies and my Beer Camp beer in a half barrel. I was too lazy to move the half barrel to get the gas line behind it so I'm running a second tank of CO2 into the sanke key to push that beer. Lazy I know. I promise this isn't a permanent thing.

My apologies for the blurry pics. My phone seems to be getting old, or it could be me.

innocentbp

Member

- Joined

- Feb 16, 2013

- Messages

- 16

- Reaction score

- 1

Amazing set up. I'm still drooling. By the way I'm Dan your beer camp #118 roommate.

Sent from my iPad using Home Brew

Sent from my iPad using Home Brew

Its good to see you using the Raspberry Pints from the DIY section. I am incredibly envious still. More so actually.

Any of you east coast dudes around CT get a chance to buy Dan a beer, do so and I will paypal you. That poor guy had to put up with my drunk ass snoring for 3 days....

Thanks for the good words Dan (and Jon)...

Thanks for the good words Dan (and Jon)...

rockinmarty

Big Member

love your co2 braided lines!!! where did you get them? I would love more details on your carbonation rig. Are the secondary regs homemade?

I get it all for cost. My cousin is a higher up for them and has set me up with a corporate account. Nothing to fear...

love your co2 braided lines!!! where did you get them? I would love more details on your carbonation rig. Are the secondary regs homemade?

The braid was from another project, Swagelok 1/4" tube adapters with SS braid over PTFE. Any local Swagelok place will have it or you can check eBay as it'll be cheaper there. The problem with Swagelok is they have their own tube fitting/tube adapters that are not compatible with others. That said, they have plenty of NPT and AN (what the homebrewers tend to call flare) adaptation so you can work it all together.

My manifold was from my old chest freezer that I carbonated in before I moved kegs to the keezer (which had a serving manifold that was one pressure only). I built it from a mix of Swagelok parts, air compressor regulators, and an old multichannel manifold that broke awhile back. I mounted everything to an aluminum plate and there you go.

I get it all for cost. My cousin is a higher up for them and has set me up with a corporate account. Nothing to fear...

You lucky sonuvab---

I am Irish so we are big into luck.

And trust me, the Swage stuff is still far from cheap, even at cost. But I don't have a wife nagging at me to buy her Coach purses so I can spend my money in a more appropriate manner...

Brewing beer is the priority at my house.

And trust me, the Swage stuff is still far from cheap, even at cost. But I don't have a wife nagging at me to buy her Coach purses so I can spend my money in a more appropriate manner...

Brewing beer is the priority at my house.

- Joined

- Mar 18, 2012

- Messages

- 2,418

- Reaction score

- 3,060

Thanks for the update with pictures. I've been following and impressed since day one and can officially hate you now.

SavoryChef

Well-Known Member

That's a lot of Jester King!! Vie en Rose is awesome

A fair amount of the Vie en Rose is due to a fellow HBT member here from Austin and he deserves a big shout out for going out of his way to collect bottles for me. I forgot his username but a big thanks to Chris from Buda for hooking it up.

My sister and I are holding a 50th wedding anniversary party in a couple weeks for my folks and we will be having the toast with 24 bottles of Vie en Rose, 3 of those being batch 1's. It took a lot of trading and kickass guys like Chris to make this happen so cheers Chris! I appreciate your efforts!

Props go out to all the Jester King people like Jeff, Michael, Averie and Nick as they are doing great things there. They deserve all the success in the world. They have built something special for sure.

My sister and I are holding a 50th wedding anniversary party in a couple weeks for my folks and we will be having the toast with 24 bottles of Vie en Rose, 3 of those being batch 1's. It took a lot of trading and kickass guys like Chris to make this happen so cheers Chris! I appreciate your efforts!

Props go out to all the Jester King people like Jeff, Michael, Averie and Nick as they are doing great things there. They deserve all the success in the world. They have built something special for sure.

SavoryChef

Well-Known Member

I have only had a couple JK and a couple more waiting patiently to be drank. They are putting out some great beers and I love their concept

It was my pleasure, John. It was certainly nice to have you in town even for such a short visit. Hope the 50th party goes well.My sister and I are holding a 50th wedding anniversary party in a couple weeks for my folks and we will be having the toast with 24 bottles of Vie en Rose, 3 of those being batch 1's. It took a lot of trading and kickass guys like Chris to make this happen so cheers Chris! I appreciate your efforts!

Chris

Calfj60

Well-Known Member

This is an absolutely amazing thread! I have enjoyed reading the whole thread from start to finish. Thank you so much for going to all the trouble to document the build,I know it slows down forward progress.

Chris is a stud everybody. A true gentlemen. Buy him a beer if you come across him and I'll pay you back if you do.

It was raining a bit here so I noticed the humidity shoot up in the cooler. Subsequently, it wasn't getting down to the set point of 37 so I investigated a bit and found some ice building up on the lower part of the AC unit. I went through the manual and changed some settings on the coolbot (heater delay, the cooling factor moved to 2 from 0) and now it's running without ice.

I dropped one of the Eva-Dry units I have in there and all the beads spilled out everywhere, causing a huge mess. I highly recommend taping the door shut where you add new beads so this does not happen. Even though I vacuumed for over an hour, I will be finding these damn beads for the next 5 years I bet. They are sneaky little bastiges those beads.

It was raining a bit here so I noticed the humidity shoot up in the cooler. Subsequently, it wasn't getting down to the set point of 37 so I investigated a bit and found some ice building up on the lower part of the AC unit. I went through the manual and changed some settings on the coolbot (heater delay, the cooling factor moved to 2 from 0) and now it's running without ice.

I dropped one of the Eva-Dry units I have in there and all the beads spilled out everywhere, causing a huge mess. I highly recommend taping the door shut where you add new beads so this does not happen. Even though I vacuumed for over an hour, I will be finding these damn beads for the next 5 years I bet. They are sneaky little bastiges those beads.

JackAssBrewer

Member

Holy thread batman! It only took a day of reading on my work computer, don't bug me I'm busy here! Krazy Kick Arse build! Big time kodos! Gotta love the DIYers

Very nice! Thanks for the follow up pics!

I'm glad people are finding the thread useful. It was a fun project and it has really helped out with bottle storage and with having a centralized location for cold crashing/kegging/serving beer. If I have a leftover pizza box, it fits right in there. I could theoretically buy more food in bulk and store it there fairly easily.

It's nice having everything in one place and my costs are lower than I expected. I've been paying less than 100 per month for my electric bill. Might go up once monsoon season hits and we get some humidity. Dog days of summer are still yet to hit. No more icing since I changed the settings on the coolbot as well.

It's nice having everything in one place and my costs are lower than I expected. I've been paying less than 100 per month for my electric bill. Might go up once monsoon season hits and we get some humidity. Dog days of summer are still yet to hit. No more icing since I changed the settings on the coolbot as well.

You guys probably won't believe this, but I was given a 900 bottle capacity wine walk in yesterday by a really nice rich guy who was moving out and needed it gone ASAP. I just checked it out online and the thing is over 5K new with the options he had bought it with (everything but the spilt panels). And that's before shipping. He used it for a 700+ bottle collection for a few years and it's in pretty nice condition.

http://www.vintagecellars.com/walk-ins/vintage-series-wine-room-900/

I think I can manage to fit this in my back bedroom and this will bring my capacity to over 1K bottles between the two units. The downside is this is only good for about 52 degrees F, so you can use it to lager ferment in, cool side fermentation temperature control for ales, and cellar bottles more or less. I doubt I would have ever bought one of these, but for free it's a fun thing to think about. I may just end up selling it as I really want to build a yeast lab in the 3rd bedroom, and this would get in the way of that...

http://www.vintagecellars.com/walk-ins/vintage-series-wine-room-900/

I think I can manage to fit this in my back bedroom and this will bring my capacity to over 1K bottles between the two units. The downside is this is only good for about 52 degrees F, so you can use it to lager ferment in, cool side fermentation temperature control for ales, and cellar bottles more or less. I doubt I would have ever bought one of these, but for free it's a fun thing to think about. I may just end up selling it as I really want to build a yeast lab in the 3rd bedroom, and this would get in the way of that...

Sounds like a great way to bulk condition/age sours.

It would also be fantastic for doing barrel age stuff.

I think you need to start shopping for wood barrels to age stuff in.

Sent from my wooden walkie talkie using Home Brew mobile

It would also be fantastic for doing barrel age stuff.

I think you need to start shopping for wood barrels to age stuff in.

Sent from my wooden walkie talkie using Home Brew mobile

I have 4 barrels at this time. A 10 gallon rum from Farmhouse Supply that has a wee heavy aging in it, as well as 3 different 5 gallon Balcones ones. In fact, I want to do a BA Abraxas clone, so this is good timing.

Glad to contribute to your "productivity" at work. Good times.

Recently, I've been seeing a lot of humidity both in and out of the cooler, as we have had over 2" of rain since the beginning of July. It is our monsoon season now so this is not unusual. Luckily the last coolbot settings adjustment I made a couple months ago have been working perfectly. No icing at all and she's holding steady at 37 F. My last electric bill was only 80 bucks, even with the AC in my room on full time. It seems like this is pretty normal and my bill was down to the low 60's over the winter.

Everything is working perfectly. I am in a quandary though as I've been brewing mostly with brett lately and all my current beers that need to be packaged except 2 are farmhouse/sours. Traditionally, I've bottled all my farmhouses, and kegged all my clean beers. When I say farmhouse, I almost always brew a mixed fermentation with brett, lacto and sacch. Saisons to me are usually clean beers with only sacch used. But I'm thinking it would be fun to have a couple brett lines that are always dedicated to funky beers. With 5 lines, I don't see this as being a big issue but I wouldn't be able to go back once I committed to this, unless I choose to replace the lines.

I'd like to hear what people have done when they are pouring both mixed and clean fermentations...

Recently, I've been seeing a lot of humidity both in and out of the cooler, as we have had over 2" of rain since the beginning of July. It is our monsoon season now so this is not unusual. Luckily the last coolbot settings adjustment I made a couple months ago have been working perfectly. No icing at all and she's holding steady at 37 F. My last electric bill was only 80 bucks, even with the AC in my room on full time. It seems like this is pretty normal and my bill was down to the low 60's over the winter.

Everything is working perfectly. I am in a quandary though as I've been brewing mostly with brett lately and all my current beers that need to be packaged except 2 are farmhouse/sours. Traditionally, I've bottled all my farmhouses, and kegged all my clean beers. When I say farmhouse, I almost always brew a mixed fermentation with brett, lacto and sacch. Saisons to me are usually clean beers with only sacch used. But I'm thinking it would be fun to have a couple brett lines that are always dedicated to funky beers. With 5 lines, I don't see this as being a big issue but I wouldn't be able to go back once I committed to this, unless I choose to replace the lines.

I'd like to hear what people have done when they are pouring both mixed and clean fermentations...

Since I had no replies on how to deal with sours/brett beers on draft, I decided to reach out to Oldsock, who is the man when it comes to all things sour.

He confirmed that basically you have to dedicate lines just to those beers and I have since done so, running through a keg of a brett saison and a keg of a raspberry wild ale that came out really excellent (think Atrial, but not quite as much raspberry). Both kegs poured perfectly and without issues. I've been busy with a bunch of work stuff but soon I'll be over that project and hopefully I'll have some time to brew a few more batches.

He confirmed that basically you have to dedicate lines just to those beers and I have since done so, running through a keg of a brett saison and a keg of a raspberry wild ale that came out really excellent (think Atrial, but not quite as much raspberry). Both kegs poured perfectly and without issues. I've been busy with a bunch of work stuff but soon I'll be over that project and hopefully I'll have some time to brew a few more batches.

Thank you to this thread for giving me the courage and resources to build my cold room.

It is much smaller scale but perfect for my needs and space. I took an existing interior garage wall and built a 3 X 5 X 7 cold room. It is cooled by an 8000 BTU air conditioner.

I use a Rancor controller and heat cable to maintain the temperature. I've been able to chill to 28 but maintain a temperature between 39 and 45. I could use a tighter range but why.

I owe great thanks to Coolbot website for the instructions to build an inexpensive room. I used the design from the Univ of Kentucky. My total cost of the room was around $1200. A buddy and I did the entire construction. Luckily he knew what he was doing.

I used 3" ABS drain pipe for my tap manifold.

It is much smaller scale but perfect for my needs and space. I took an existing interior garage wall and built a 3 X 5 X 7 cold room. It is cooled by an 8000 BTU air conditioner.

I use a Rancor controller and heat cable to maintain the temperature. I've been able to chill to 28 but maintain a temperature between 39 and 45. I could use a tighter range but why.

I owe great thanks to Coolbot website for the instructions to build an inexpensive room. I used the design from the Univ of Kentucky. My total cost of the room was around $1200. A buddy and I did the entire construction. Luckily he knew what he was doing.

I used 3" ABS drain pipe for my tap manifold.

Well done menisale! I'm happy to see this thread inspired someone else to kick some ass!

It has been a while since I have posted on this thread, but I figured I should post up as I have a couple of safety/function related upgrades I am making. I also wanted to report that the cooler is running perfectly and I haven't had any issues. In short, this thing is pretty incredible. After having it for almost 2 years now, I doubt I would want to go back to a keezer or multiple refrigerators. My electric bill is very reasonable and I think I am actually saving money over having all the chest freezers before. I dread having to move (no plans to do so, but I hope I don't ever have to). If you can afford it, I highly recommend doing this.

So one detail I was worried about was the gas cylinder I use for the draft system was not secured in any way. So recently I machined a plate to mount to my draft frame that I can secure a gas cylinder mount to:

So one detail I was worried about was the gas cylinder I use for the draft system was not secured in any way. So recently I machined a plate to mount to my draft frame that I can secure a gas cylinder mount to:

I have a couple questions about your build, as I am currently in the planning phase of my own.

First are your still happy with the energy usage?

Second, did you have any info on the r-value of the cooler panels that you used? I have a lead on some decently priced used panels, but I haven't been able to find any info yet.

First are your still happy with the energy usage?

Second, did you have any info on the r-value of the cooler panels that you used? I have a lead on some decently priced used panels, but I haven't been able to find any info yet.

I am very happy. I had a 52 dollar electric bill last month. Granted it was cooler than normal as we have had a lot of rain this year. But I don't see it getting over 75 bucks very often, and this includes my whole house, with a window AC unit in my bedroom. I am running a regular fridge, a chest freezer and a fermentation fridge as well (usually set at 66).

Walk in cooler panels have an industry standard R value of 26. I imagine this will degrade over time but that's a good number to start.

Walk in cooler panels have an industry standard R value of 26. I imagine this will degrade over time but that's a good number to start.

I am very happy. I had a 52 dollar electric bill last month. Granted it was cooler than normal as we have had a lot of rain this year. But I don't see it getting over 75 bucks very often, and this includes my whole house, with a window AC unit in my bedroom. I am running a regular fridge, a chest freezer and a fermentation fridge as well (usually set at 66).

Walk in cooler panels have an industry standard R value of 26. I imagine this will degrade over time but that's a good number to start.

What's your rate?

Similar threads

- Replies

- 3

- Views

- 804

- Replies

- 7

- Views

- 847