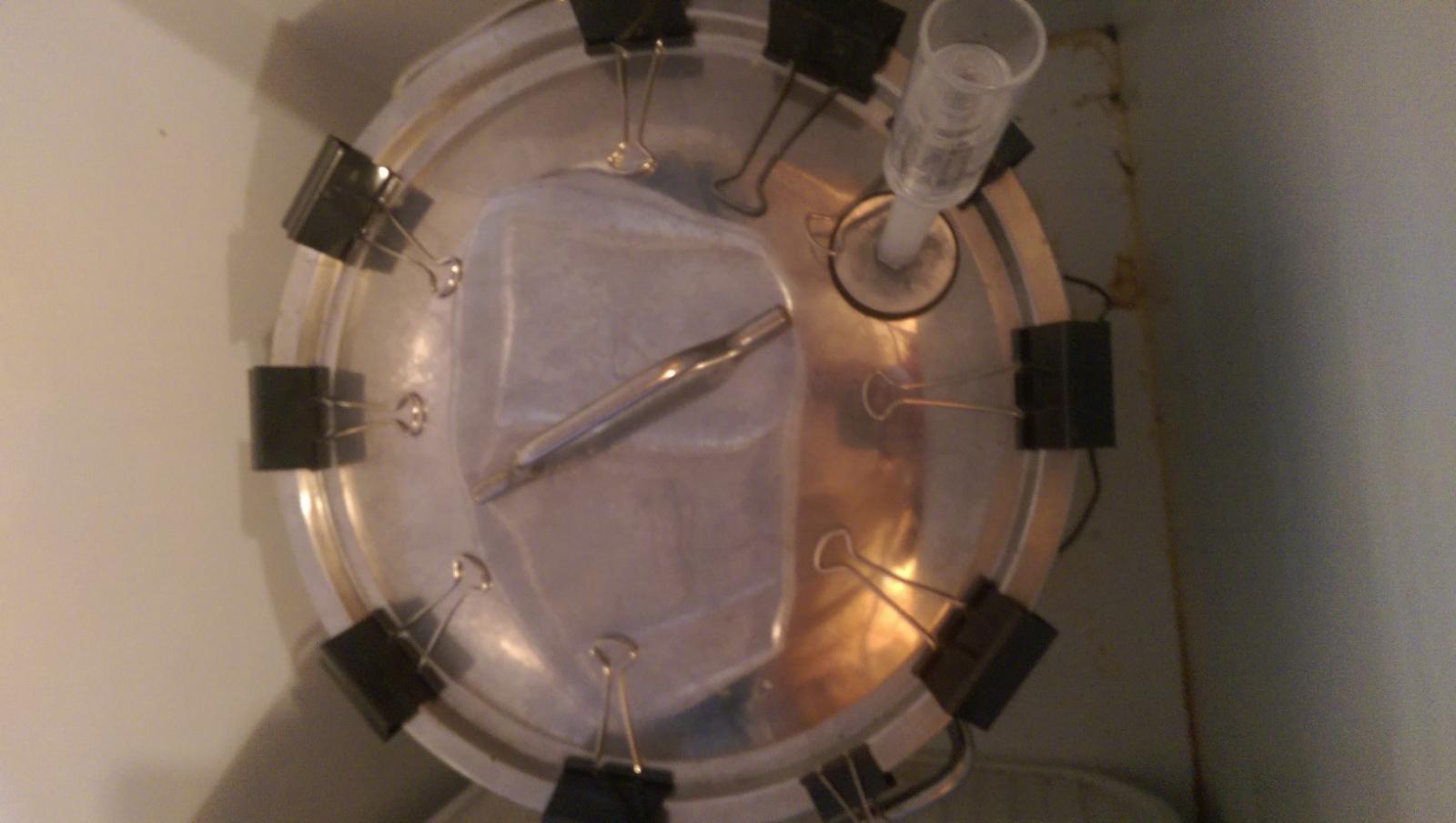

I built this fermenter but modified it some with the following parts:

-44qt Bayou pot (allows 10-10.5 gal brews)

http://goo.gl/2epnWf

-Added a Italian Bottling Bucket spigot (bought at my local HBS for ~$2)

http://goo.gl/oELLYM

-Added a 6" SS 1/4" npt weldless thermowell from BrewHardware -

https://www.brewhardware.com/product_p/mwl14thermowell.htm

-Lined the edge of the pot with 1/2"ID silicone tubing ~4ft long. I think smaller 3/8"ID tubing would work fine too

-Glued the ends of the silicone together with Permatex RTX silicone sealant

http://goo.gl/qfmkDc

-In the lid, drilled a hole and added: 1/4 MFL x 1/8 MPT SS half union (

http://www.chicagobrewwerks.com/stainless-steel-half-union-1-4-mfl-x-1-8-mpt/dp/1555), 2" SS washer with 1/4" hole, 2" rubber washer (~1/16" thick), pot lid, rubber washer, 2" SS washer, 1/8" SS nut (all from Lowes)

-Use large binder clips from Staples to keep lid sealed

The Italian bottling bucket spigot was super cheap compared to buying another big 1/2" SS valve. It is easily removable, very replaceable. Another nice feature is the faucet out portion of it can swivel up or down, which allows you to move it out of the way when transporting the fermenter. It also keeps the spigot from touching the bottom of the fermentation chamber (chest freezer) floor.

The thermowell installed very easily and allows me to monitor temps with my STC-1000 controller.

For the sealing rim tubing, I cut a length wise split in the tubing and then fit it to the pot. For the first batch I made, the ends of the tubing were not glued together. When silicone tubing gets cold (ie in fermentation box), it shrinks. Well my first batch got infected because the ends of the tubing pulled apart about 1/2" and allowed dirty air into the brew. I end up gluing the tubing edges together using the RTV silicone adhesive. Do this by cutting a small portion (~3-4") of 1/2" OD vinyl tubing, fitting it inside the 1/2" ID silicone tubing, and zip-tying the silicone tubing around the vinyl tubing, leaving about 1/8" gap between the end edges of the silicone tubing. Inject the adhesive in the gap evenly, cover with saranwrap and leave to cure for a few days. Works great now!

In the lid I wanted a 1/4" MFL barb so that I could attached my CO2 hose, fill the head space with CO2 and push the beer oxygen-free into the secondary/keg/etc. I jerry-rigged a sealing attachment using parts from Lowes to seal the hole in the lid and securely attach the 1/4 MFL x 1/8 MPT SS half union (bought from local HBS for ~$3). This part is sold at your HBS with the Blichman beer gun accessories. You can find a copper/brass version at any home improvement store (which is fine, it's never soaking in the beer). The 1/4" barb also allows me to affix a blow-off tube to it, or as in the picture, a short length of tubing and an airlock. I am able to push the beer out and keep the lid sealed with about 2-5 PSI and that works fine. No need to pressurize to 20PSI.

Right now I'm using binder clips to keep the lid on and it works fine, except that they rust in wet areas.

Nobody has mentioned this in the thread above. Rust stains are gross when on your SS fermenter and next to your finished beer! At some point, I plan to rig up some sort of lid clips riveted to the side of the pot (as others in this thread have dabbled with).

Lastly, it is worth noting the Bayou pot is the thinnest, crappiest stainless steel pot I've ever seen. The handle welds show up as black dent/bumps inside the pot. The outside of the pot/lid show every little water spot. It dings and dents with almost no effort. Drilling the hole for the spigot using a step bit ended up warping the side of the pot. It works fine in this application as a fermenter, but I would NEVER use a Bayou pot for boil kettle/HLT/MLT. Anyone that does is either super cheap and/or lying through their teeth when they post to HBT about how great the pot is.

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)