You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

DIY Stainless Steel Fermenters

- Thread starter Brewzologist

- Start date

Help Support Homebrew Talk - Beer, Wine, Mead, & Cider Brewing Discussion Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

shoreman

Well-Known Member

- Joined

- Feb 1, 2012

- Messages

- 1,346

- Reaction score

- 396

I've been interested in building one of these as well.

Those clips will work, this guy on youtube uses them:

http://youtu.be/YXKw6l0J0Sc

Pretty similar setup.

Also the SS conical company sells the rotating racking arm as an accessory so you could install that.

Update us when you put it through a couple of brews.

Those clips will work, this guy on youtube uses them:

http://youtu.be/YXKw6l0J0Sc

Pretty similar setup.

Also the SS conical company sells the rotating racking arm as an accessory so you could install that.

Update us when you put it through a couple of brews.

Bensiff

Well-Known Member

- Joined

- Mar 13, 2008

- Messages

- 4,835

- Reaction score

- 411

The big issue I had when looking into doing the same was finding latches that would work as you are not latching straight across as many are designed to do. I had a welder fabricate some latches and he came up with a rather nice design.

Minbari

Well-Known Member

- Joined

- Apr 29, 2014

- Messages

- 376

- Reaction score

- 61

What size is that? Looks great.

its a 4 gallon pot. of course you could do it with any size you like.

The big issue I had when looking into doing the same was finding latches that would work as you are not latching straight across as many are designed to do. I had a welder fabricate some latches and he came up with a rather nice design.

I am sure my solution is not perfect, but it seals really well and the double hindge pulls down the lid nicely. if you dont secure the latches, they pop back open. (gonna replace those little pieces of wire with pins that wont fall out)

Bensiff

Well-Known Member

- Joined

- Mar 13, 2008

- Messages

- 4,835

- Reaction score

- 411

I am sure my solution is not perfect, but it seals really well and the double hindge pulls down the lid nicely. if you dont secure the latches, they pop back open. (gonna replace those little pieces of wire with pins that wont fall out)

That is exactly what I was concerned about when I started researching those types of hinges. It didn't occur to me to use pins to force them to keep latched, good thought. My welder came up with a nice hinge design that is extremely beefy, I suppose they live up to the Stout Tanks namesake which they are welded to. I'm on my first experimental run, made a gasket with some vinyl tubing that holds pressure surprisingly well; but will move over to silicone next go around.

Thanks for this thread. I have had a SS pot fermenter for the past few years and can not get a seal. I wanted to see through so I made a Plexiglass lid and clamp it down with J bolts on the pot handles. After seeing this thread it is so obvious to me now. I will add some C-clamps around the edges and it will probably finally work!

The 9 gallon pot cost $59 and I had a SS 1/2" pipe nipple welded on for transfers. Couldn't be a better way to ferment, especially once I get it to seal. Fits inside a wine fridge, easy to clean and since it is 9 gallons, the kreusen never reaches the lid. I agree that the seal is not the end of the world, but having the airlock bubble would kind of make it official...

The 9 gallon pot cost $59 and I had a SS 1/2" pipe nipple welded on for transfers. Couldn't be a better way to ferment, especially once I get it to seal. Fits inside a wine fridge, easy to clean and since it is 9 gallons, the kreusen never reaches the lid. I agree that the seal is not the end of the world, but having the airlock bubble would kind of make it official...

milldoggy

Well-Known Member

Some good prices on eBay for pots,30 quart concord is only 40$. Makes for a cheap fermentor

reelmower

Well-Known Member

I'm interested in your silicone tubing gasket. Do you have to seal the ends of your tubing .. or does the pressure from the lid create the seal. Seems like 20 psi .. would leak out without sealed ends? I tried something similar with some beverage tubing .. which is rigid .. and I had to put a dab of keg lube on the ends of my gasket. 2-3 psi would blow the keg lube out. I couldn't get enough pressure on the lid with the beverage tubing gasket to hold any amount of pressure. My goal is to push my beer with CO2 .. and only need about 3 psi.

alexc2013

Member

- Joined

- Dec 8, 2013

- Messages

- 13

- Reaction score

- 6

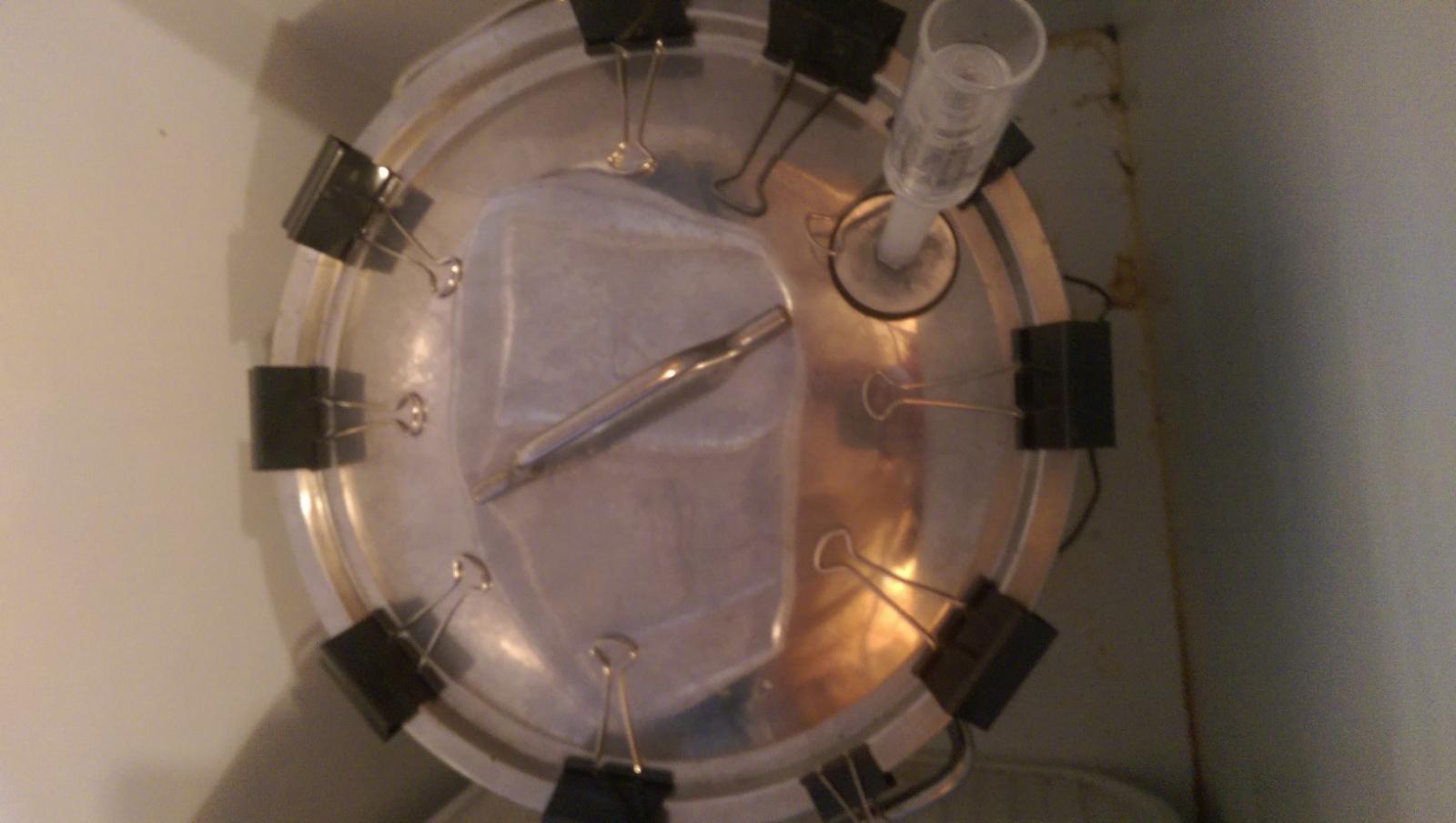

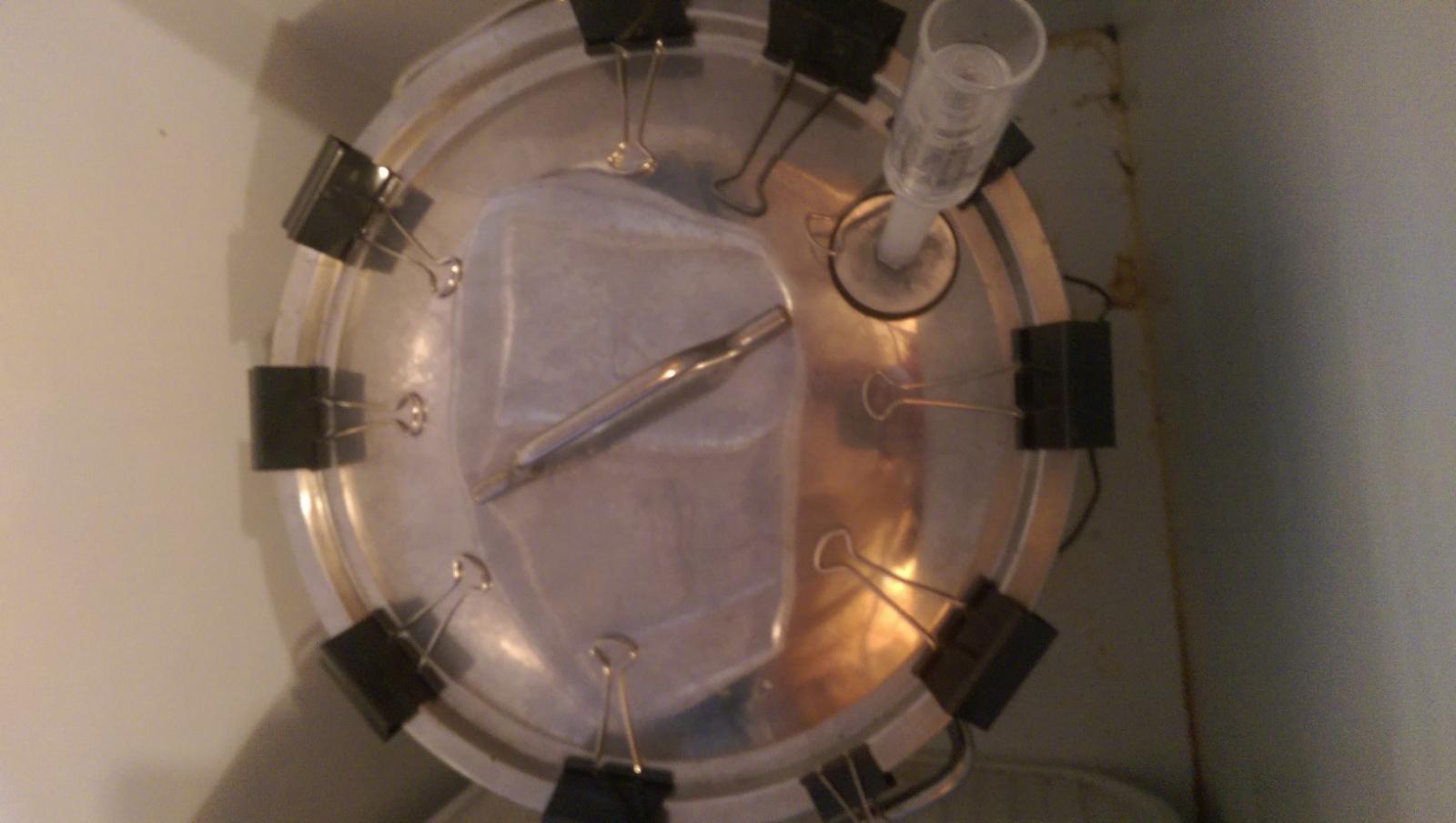

I built this fermenter but modified it some with the following parts:

-44qt Bayou pot (allows 10-10.5 gal brews) http://goo.gl/2epnWf

-Added a Italian Bottling Bucket spigot (bought at my local HBS for ~$2) http://goo.gl/oELLYM

-Added a 6" SS 1/4" npt weldless thermowell from BrewHardware - https://www.brewhardware.com/product_p/mwl14thermowell.htm

-Lined the edge of the pot with 1/2"ID silicone tubing ~4ft long. I think smaller 3/8"ID tubing would work fine too

-Glued the ends of the silicone together with Permatex RTX silicone sealant http://goo.gl/qfmkDc

-In the lid, drilled a hole and added: 1/4 MFL x 1/8 MPT SS half union (http://www.chicagobrewwerks.com/stainless-steel-half-union-1-4-mfl-x-1-8-mpt/dp/1555), 2" SS washer with 1/4" hole, 2" rubber washer (~1/16" thick), pot lid, rubber washer, 2" SS washer, 1/8" SS nut (all from Lowes)

-Use large binder clips from Staples to keep lid sealed

The Italian bottling bucket spigot was super cheap compared to buying another big 1/2" SS valve. It is easily removable, very replaceable. Another nice feature is the faucet out portion of it can swivel up or down, which allows you to move it out of the way when transporting the fermenter. It also keeps the spigot from touching the bottom of the fermentation chamber (chest freezer) floor.

The thermowell installed very easily and allows me to monitor temps with my STC-1000 controller.

For the sealing rim tubing, I cut a length wise split in the tubing and then fit it to the pot. For the first batch I made, the ends of the tubing were not glued together. When silicone tubing gets cold (ie in fermentation box), it shrinks. Well my first batch got infected because the ends of the tubing pulled apart about 1/2" and allowed dirty air into the brew. I end up gluing the tubing edges together using the RTV silicone adhesive. Do this by cutting a small portion (~3-4") of 1/2" OD vinyl tubing, fitting it inside the 1/2" ID silicone tubing, and zip-tying the silicone tubing around the vinyl tubing, leaving about 1/8" gap between the end edges of the silicone tubing. Inject the adhesive in the gap evenly, cover with saranwrap and leave to cure for a few days. Works great now!

In the lid I wanted a 1/4" MFL barb so that I could attached my CO2 hose, fill the head space with CO2 and push the beer oxygen-free into the secondary/keg/etc. I jerry-rigged a sealing attachment using parts from Lowes to seal the hole in the lid and securely attach the 1/4 MFL x 1/8 MPT SS half union (bought from local HBS for ~$3). This part is sold at your HBS with the Blichman beer gun accessories. You can find a copper/brass version at any home improvement store (which is fine, it's never soaking in the beer). The 1/4" barb also allows me to affix a blow-off tube to it, or as in the picture, a short length of tubing and an airlock. I am able to push the beer out and keep the lid sealed with about 2-5 PSI and that works fine. No need to pressurize to 20PSI.

Right now I'm using binder clips to keep the lid on and it works fine, except that they rust in wet areas. Nobody has mentioned this in the thread above. Rust stains are gross when on your SS fermenter and next to your finished beer! At some point, I plan to rig up some sort of lid clips riveted to the side of the pot (as others in this thread have dabbled with).

Lastly, it is worth noting the Bayou pot is the thinnest, crappiest stainless steel pot I've ever seen. The handle welds show up as black dent/bumps inside the pot. The outside of the pot/lid show every little water spot. It dings and dents with almost no effort. Drilling the hole for the spigot using a step bit ended up warping the side of the pot. It works fine in this application as a fermenter, but I would NEVER use a Bayou pot for boil kettle/HLT/MLT. Anyone that does is either super cheap and/or lying through their teeth when they post to HBT about how great the pot is.

-44qt Bayou pot (allows 10-10.5 gal brews) http://goo.gl/2epnWf

-Added a Italian Bottling Bucket spigot (bought at my local HBS for ~$2) http://goo.gl/oELLYM

-Added a 6" SS 1/4" npt weldless thermowell from BrewHardware - https://www.brewhardware.com/product_p/mwl14thermowell.htm

-Lined the edge of the pot with 1/2"ID silicone tubing ~4ft long. I think smaller 3/8"ID tubing would work fine too

-Glued the ends of the silicone together with Permatex RTX silicone sealant http://goo.gl/qfmkDc

-In the lid, drilled a hole and added: 1/4 MFL x 1/8 MPT SS half union (http://www.chicagobrewwerks.com/stainless-steel-half-union-1-4-mfl-x-1-8-mpt/dp/1555), 2" SS washer with 1/4" hole, 2" rubber washer (~1/16" thick), pot lid, rubber washer, 2" SS washer, 1/8" SS nut (all from Lowes)

-Use large binder clips from Staples to keep lid sealed

The Italian bottling bucket spigot was super cheap compared to buying another big 1/2" SS valve. It is easily removable, very replaceable. Another nice feature is the faucet out portion of it can swivel up or down, which allows you to move it out of the way when transporting the fermenter. It also keeps the spigot from touching the bottom of the fermentation chamber (chest freezer) floor.

The thermowell installed very easily and allows me to monitor temps with my STC-1000 controller.

For the sealing rim tubing, I cut a length wise split in the tubing and then fit it to the pot. For the first batch I made, the ends of the tubing were not glued together. When silicone tubing gets cold (ie in fermentation box), it shrinks. Well my first batch got infected because the ends of the tubing pulled apart about 1/2" and allowed dirty air into the brew. I end up gluing the tubing edges together using the RTV silicone adhesive. Do this by cutting a small portion (~3-4") of 1/2" OD vinyl tubing, fitting it inside the 1/2" ID silicone tubing, and zip-tying the silicone tubing around the vinyl tubing, leaving about 1/8" gap between the end edges of the silicone tubing. Inject the adhesive in the gap evenly, cover with saranwrap and leave to cure for a few days. Works great now!

In the lid I wanted a 1/4" MFL barb so that I could attached my CO2 hose, fill the head space with CO2 and push the beer oxygen-free into the secondary/keg/etc. I jerry-rigged a sealing attachment using parts from Lowes to seal the hole in the lid and securely attach the 1/4 MFL x 1/8 MPT SS half union (bought from local HBS for ~$3). This part is sold at your HBS with the Blichman beer gun accessories. You can find a copper/brass version at any home improvement store (which is fine, it's never soaking in the beer). The 1/4" barb also allows me to affix a blow-off tube to it, or as in the picture, a short length of tubing and an airlock. I am able to push the beer out and keep the lid sealed with about 2-5 PSI and that works fine. No need to pressurize to 20PSI.

Right now I'm using binder clips to keep the lid on and it works fine, except that they rust in wet areas. Nobody has mentioned this in the thread above. Rust stains are gross when on your SS fermenter and next to your finished beer! At some point, I plan to rig up some sort of lid clips riveted to the side of the pot (as others in this thread have dabbled with).

Lastly, it is worth noting the Bayou pot is the thinnest, crappiest stainless steel pot I've ever seen. The handle welds show up as black dent/bumps inside the pot. The outside of the pot/lid show every little water spot. It dings and dents with almost no effort. Drilling the hole for the spigot using a step bit ended up warping the side of the pot. It works fine in this application as a fermenter, but I would NEVER use a Bayou pot for boil kettle/HLT/MLT. Anyone that does is either super cheap and/or lying through their teeth when they post to HBT about how great the pot is.

Your post was educational and informative... Yes, until the point where you felt the need to pointlessly bad mouth many Brewers for their equipment preference. Apparently I am very cheap and regularly lie through my teeth when I recommend the bayou pot that I use and find works very well.

Although my opinion is probably invalid since I've actually used it as a brew kettle...

Although my opinion is probably invalid since I've actually used it as a brew kettle...

beersk

Well-Known Member

- Joined

- Mar 22, 2013

- Messages

- 1,850

- Reaction score

- 1,025

No problems with Bayou Classic kettles here either. I think they're great.

Great idea and great thread, OP! I've been looking at way to ferment in a kettle as well. Maybe you could just put some weight on the lid instead of using clamps. That's what I've always imagined doing anyway, the silicone ring for the seal is the key component!

Wilserbrewer, I see what you're saying, but I brew lagers as well and want my fermenters to be able to seal.

Great idea and great thread, OP! I've been looking at way to ferment in a kettle as well. Maybe you could just put some weight on the lid instead of using clamps. That's what I've always imagined doing anyway, the silicone ring for the seal is the key component!

Wilserbrewer, I see what you're saying, but I brew lagers as well and want my fermenters to be able to seal.

alexc2013

Member

- Joined

- Dec 8, 2013

- Messages

- 13

- Reaction score

- 6

Your post was educational and informative... Yes, until the point where you felt the need to pointlessly bad mouth many Brewers for their equipment preference. Apparently I am very cheap and regularly lie through my teeth when I recommend the bayou pot that I use and find works very well.

Although my opinion is probably invalid since I've actually used it as a brew kettle...

I'm clearly cheap too. I've jerry-rigged just about every aspect of my brewing setup and have had successes and failures. I've realized that there is a lot of brilliant ideas on HBT and there's also a lot of chest-thumping bull**** ideas that only serve lead others astray. I've also used friends' Bayou pots as brew kettles and HLTs, and they all have the same problems with the flimsy, easily dent-able pots. If you have converted a Bayou pot into this thread's referenced fermenter, fine please share your opinion. Otherwise, spare everyone else the hot air.

Bensiff

Well-Known Member

- Joined

- Mar 13, 2008

- Messages

- 4,835

- Reaction score

- 411

Once again it must be noted that you get what you pay for. Want a cheap stainless kettle, bayou is as good as any other. That means 20 gauge or .8mm construction instead of 1 or 1.2mm construction of much more expensive kettles. I don't really see the issue though as .8mm is more than enough to hold the contents inside and not be flimsy unless one is moving it around when full. But if one moves a kettle around when full I would argue the real issue isn't the kettle, it is the brewery design that requires something asking for injury or damage. The whole point of the thread is to build a cheap stainless fermenter, it wouldn't really work if you start with an expensive kettle.

Brewzologist

Active Member

Update: Posted an edit to the original post about sealing the ends of the gasket and added a pic.

After many batches this rig is still working fine. Sold off my glass carboys and I'm now committed to this setup. Haven't taken the plunge to add a drain valve, and don't think I will as the auto-siphon works well for my setup. May add a grommet or bushing to the sharp edges of the hole in the lid, though, because it cuts the stopper pretty good after awhile. Glad to hear this idea is working well for you all, and thanks adding some good ideas of your own!

Steve

After many batches this rig is still working fine. Sold off my glass carboys and I'm now committed to this setup. Haven't taken the plunge to add a drain valve, and don't think I will as the auto-siphon works well for my setup. May add a grommet or bushing to the sharp edges of the hole in the lid, though, because it cuts the stopper pretty good after awhile. Glad to hear this idea is working well for you all, and thanks adding some good ideas of your own!

Steve

milldoggy

Well-Known Member

I wonder if edge trim would work. McMaster Carr has a few different kinds, here is one

http://www.mcmaster.com/#silicone-rubber-edge-trim/=vifwxo

http://www.mcmaster.com/#silicone-rubber-edge-trim/=vifwxo

milldoggy

Well-Known Member

one more type.

http://www.mcmaster.com/#edge-seals/=vifyoh

http://www.mcmaster.com/#edge-seals/=vifyoh

Ike

nOob for life

- Joined

- Jan 9, 2015

- Messages

- 532

- Reaction score

- 186

Giving this bad boy a BUMP!

I'd posted something in the beginner's forum about fermenting in the boil kettle, and a poster pointed me here. AWESOME THREAD! JUST what I had in mind.

QUESTION: has anyone tried just weighing down the lid with something heavy, rather than bothering with all the clamps? Especially since it seems like some folks have been doing it with no silicone seal OR clamps... I was thinking about building one up with the silicone seal, then just using a brick or two (maybe wrap them in tape or plastic to keep them from scratching the lid) on top of the lid? There should still be plenty of room for the airlock/blowoff.

Again, thanks for the epic thread!

Ike

I'd posted something in the beginner's forum about fermenting in the boil kettle, and a poster pointed me here. AWESOME THREAD! JUST what I had in mind.

QUESTION: has anyone tried just weighing down the lid with something heavy, rather than bothering with all the clamps? Especially since it seems like some folks have been doing it with no silicone seal OR clamps... I was thinking about building one up with the silicone seal, then just using a brick or two (maybe wrap them in tape or plastic to keep them from scratching the lid) on top of the lid? There should still be plenty of room for the airlock/blowoff.

Again, thanks for the epic thread!

Ike

OP, I'm glad someone bumped this thread. This is genius. I've been trying to think about what I'll do with my 5 gallon pot when I am done building my HERMs system and this is exactly what I'll do with it.

I was googling for latch clamps and I found these:

http://www.thetoggleclampstore.com/40334.html

Expensive, but I wonder if they'd work. There are lots of options and one linked in this thread was a $6 per unit option but the $15.00 shipping killed the deal for me.

Weighing it down with something heavy? Finally a use for my old textbooks!

I was googling for latch clamps and I found these:

http://www.thetoggleclampstore.com/40334.html

Expensive, but I wonder if they'd work. There are lots of options and one linked in this thread was a $6 per unit option but the $15.00 shipping killed the deal for me.

Giving this bad boy a BUMP!

I'd posted something in the beginner's forum about fermenting in the boil kettle, and a poster pointed me here. AWESOME THREAD! JUST what I had in mind.

QUESTION: has anyone tried just weighing down the lid with something heavy, rather than bothering with all the clamps? Especially since it seems like some folks have been doing it with no silicone seal OR clamps... I was thinking about building one up with the silicone seal, then just using a brick or two (maybe wrap them in tape or plastic to keep them from scratching the lid) on top of the lid? There should still be plenty of room for the airlock/blowoff.

Again, thanks for the epic thread!

Ike

Weighing it down with something heavy? Finally a use for my old textbooks!

View attachment ImageUploadedByHome Brew1425319339.185623.jpg here is a fermenter I made from a keg that had it's base crushed. Cut off the base, welded on an 8" tri clover ferrule for easy cleaning.

- Joined

- Jun 12, 2014

- Messages

- 574

- Reaction score

- 191

View attachment 260400 here is a fermenter I made from a keg that had it's base crushed. Cut off the base, welded on an 8" tri clover ferrule for easy cleaning.

that is pretty darn neat.

Islandboy85

Well-Known Member

View attachment 260400 here is a fermenter I made from a keg that had it's base crushed. Cut off the base, welded on an 8" tri clover ferrule for easy cleaning.

Do you have issues with moving the fermenter now that the handles are cut off, or do you just leave it where it's at all the time?

I don't have a problem moving when empty. There is a 2" tri clover clamp and cap on the bottom. I put it outside, or over a drain in the basement and flush and clean it. With the 8" opening I can reach in and scrub out any residue. There is a 3/4" tube on the top for a vent, 1/2" tube for transfer and 3/8" with a valve for CO2 to push beer out to kegs. I don't open it till beer is transferred.

Islandboy85

Well-Known Member

I don't have a problem moving when empty. There is a 2" tri clover clamp and cap on the bottom. I put it outside, or over a drain in the basement and flush and clean it. With the 8" opening I can reach in and scrub out any residue. There is a 3/4" tube on the top for a vent, 1/2" tube for transfer and 3/8" with a valve for CO2 to push beer out to kegs. I don't open it till beer is transferred.

It looks really great. I'm very close to modifying a spare keg I have lying around to use as a fermenter. It's just too hard for me (I know some people use pumps to clean them) to clean out the keg through a 2" hole. Since the 8" triclover a cost so much more I thought I might go with the 6". I've got small arms, so I think I can manage. I like your simplicity of just using a cap on the bottom. That certainly saves a lot of coin.

You might be able to down to a 4", even if you can't get your arm all the way in you could get a brush in to clean it, or soak with pbw flush and rinse. The stainless cleans pretty easy if done right away.

Islandboy85

Well-Known Member

You might be able to down to a 4", even if you can't get your arm all the way in you could get a brush in to clean it, or soak with pbw flush and rinse. The stainless cleans pretty easy if done right away.

I thought that as well, but 6" is pretty cheap too if you get it from the right place. I've found that the price goes up exponentially larger than 6".

CaribouSlobber

New Member

- Joined

- Mar 6, 2015

- Messages

- 1

- Reaction score

- 0

That's pretty awesome.

I thought that as well, but 6" is pretty cheap too if you get it from the right place. I've found that the price goes up exponentially larger than 6".

Where is the right place ?

I'm about to do this with 4" triclover flanges. FWIW, the opening on a corny keg is 3" x 4". A 4" triclover flange is larger.

I have big arms. I can get up to my bicep through the 4" triclover. I have to stop at my forearm on the corny kegs. I'd love to have 6" ports, they would rock.

I thought about the stock pots for fermenting and even ordered clips to hold the lids down. But... they won't hold pressure and I need long term, air tight, pressure capable lagering vessels, so I am going with 1/2 and 1/4 barrel Sanke kegs. I want to filter my beer by pushing it with CO2, so that pretty much necessitates the Sanke kegs.

Triclover Port Cost Comparison

4" ferrule (long) $9

4" cap $10.50

4" clamp $10.00

Total $29.50

6" ferrule (long) $20

6" cap $31

6" clamp $28

Total $70

Source: BrewersHardware.com

I like the stainless steel fermentors as well, but I took a slightly different route.

I'm using stainless steel milk cans, and silver soldering tri-clamps onto them.

Large opening, easy to clean, a little pricey, but I think it's worth it.

The only real downside for me is lifting those things full into my chest freezer fermentation device, so I'm looking at building a couple of fermentation chambers to house them.

I'm using stainless steel milk cans, and silver soldering tri-clamps onto them.

Large opening, easy to clean, a little pricey, but I think it's worth it.

The only real downside for me is lifting those things full into my chest freezer fermentation device, so I'm looking at building a couple of fermentation chambers to house them.

Islandboy85

Well-Known Member

Where is the right place ?

I'm about to do this with 4" triclover flanges. FWIW, the opening on a corny keg is 3" x 4". A 4" triclover flange is larger.

I have big arms. I can get up to my bicep through the 4" triclover. I have to stop at my forearm on the corny kegs. I'd love to have 6" ports, they would rock.

I thought about the stock pots for fermenting and even ordered clips to hold the lids down. But... they won't hold pressure and I need long term, air tight, pressure capable lagering vessels, so I am going with 1/2 and 1/4 barrel Sanke kegs. I want to filter my beer by pushing it with CO2, so that pretty much necessitates the Sanke kegs.

Triclover Port Cost Comparison

4" ferrule (long) $9

4" cap $10.50

4" clamp $10.00

Total $29.50

6" ferrule (long) $20

6" cap $31

6" clamp $28

Total $70

Source: BrewersHardware.com

This is another option. When I do my electric conversion I'll use their element guards. They're a lot cheaper. Some of their other TC is more expensive. You'll need to compare between Brewers Hardware and Still Dragon. I think I'll end up ordering from both places when it's all said and done.

I like the stainless steel fermentors as well, but I took a slightly different route.

I'm using stainless steel milk cans, and silver soldering tri-clamps onto them.

Large opening, easy to clean, a little pricey, but I think it's worth it.

The only real downside for me is lifting those things full into my chest freezer fermentation device, so I'm looking at building a couple of fermentation chambers to house them.

Nice, but unless you find them on sale, they are $160 each plus shipping ($30 each) plus the triclamp hardware, plus welding.

You can buy brand new 7.75 gallon Sanke kegs for $100 here

http://www.beveragefactory.com/draf...egco-HS-K7.75G-DTHRDI-keg-threaded-valve.html

The 15.5 gallon kegs are $125 each.

http://www.beveragefactory.com/draftbeer/home_brew/kegs/Kegco_KEG1215_drop_in_valve.html

You can probably get them cheaper if you buy more than 1 and tell them you don't need the valve assembly.

Sanke kegs are made to hold pressure, ie rounded bottoms. Those milk cans are not.

Edit: here they are cheaper yet. 1/4 barrel for $87 each.

http://conical-fermenter.com/Kegs-and-Firkins/

First, I don't weld, so cutting and welding on a 4" or 6" Tri-Clamp isn't an option for me. Silver soldering the 1" and 1.5" tri-clamp ferrules is a piece of cake.

Second, I'm using a blowoff tube, so pressure is not a concern.

Third, the link I showed is $175 with free shipping, not the $190 you mentioned. Also the kegs you showed do not include shipping.

I have several 7.5 and 15.5 gal sankes, and have used them with the brewhardware sanke kit, and they work just fine. I don't like that I can't visually inspect for cleanliness that easily, even though I use a spinning carboy cleaner to clean them.

To each his own, I'm just showing another option.

Second, I'm using a blowoff tube, so pressure is not a concern.

Third, the link I showed is $175 with free shipping, not the $190 you mentioned. Also the kegs you showed do not include shipping.

I have several 7.5 and 15.5 gal sankes, and have used them with the brewhardware sanke kit, and they work just fine. I don't like that I can't visually inspect for cleanliness that easily, even though I use a spinning carboy cleaner to clean them.

To each his own, I'm just showing another option.

Third, the link I showed is $175 with free shipping, not the $190 you mentioned. Also the kegs you showed do not include shipping.

The cans in the link you showed looks different than the can on your blog. Specifically the lid. I really like your cans. Nice touch soldering on the Tri Clover ports.

The 1/4 barrel kegs are $30 each to ship.

View attachment 260400 here is a fermenter I made from a keg that had it's base crushed. Cut off the base, welded on an 8" tri clover ferrule for easy cleaning.

This is a cool fermenter. I like it. Now if I can only figure out a way for a non welder (me) to attach the fittings. Or maybe I can cut out/grind away the top hold and use an old spare Corny lid. May need to work with shortening the legs though.

Now that is super cool looking. Why all of the ports though?I like the stainless steel fermentors as well, but I took a slightly different route.

I'm using stainless steel milk cans, and silver soldering tri-clamps onto them.

Large opening, easy to clean, a little pricey, but I think it's worth it.

The only real downside for me is lifting those things full into my chest freezer fermentation device, so I'm looking at building a couple of fermentation chambers to house them.

srice

Well-Known Member

- Joined

- Oct 21, 2012

- Messages

- 262

- Reaction score

- 58

I like the stainless steel fermentors as well, but I took a slightly different route.

I'm using stainless steel milk cans, and silver soldering tri-clamps onto them.

Large opening, easy to clean, a little pricey, but I think it's worth it.

The only real downside for me is lifting those things full into my chest freezer fermentation device, so I'm looking at building a couple of fermentation chambers to house them.

Do you know the diameter of these milk cans? I'm looking for a good option which will fit in a chest freezer.

Similar threads

- Replies

- 39

- Views

- 759

- Replies

- 0

- Views

- 580

- Replies

- 4

- Views

- 427

- Replies

- 1

- Views

- 492