The extension does not, but I'm not worried about that. In an active fermentation the yeast are moving things around quite a bit. The ss keg also conducts the heat/cold around pretty well. I would recommend using a thermowell down the center of the keg. Normally during fermentation it is only on for a couple minutes at a time.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

DIY glycol chilled plastic conical fermenters

- Thread starter packet

- Start date

Help Support Homebrew Talk:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

The extension does not, but I'm not worried about that. In an active fermentation the yeast are moving things around quite a bit. The ss keg also conducts the heat/cold around pretty well. I would recommend using a thermowell down the center of the keg. Normally during fermentation it is only on for a couple minutes at a time.

Yea I have the Sanke Fermentor Kit from Brewers Hardware so I already have a thermowell. I forgot to ask, do you also use a heat supply? Right now I just use one of those Blue Brew Belts, and it works great, but I didn't know if you could using something like that underneath the cooling jacket.

Last edited by a moderator:

I made my own using a roll of flex watt (like this: http://www.ebay.com/itm/Flex-Watt-Heat-Tape-Reptile-Pet-Terrarium-Cage-Egg-Incubator-Heater-Warmer-/230921106672?pt=LH_DefaultDomain_0&var=&hash=item35c3f874f0) that I cut down do the sizes I needed. I used the 7" so it would fit in between the ridges of the keg easier. I think I used 3' for each? No issues with the jacket, I actually use it to hold my flexwatt on by wrapping it on the outside of it and velcroing the whole thing together.

And if you haven't seen this thread yet, it will really blow your mind: https://www.homebrewtalk.com/f258/stc-1000-a-464348/

I slowly ramp up to about 72 after the initial 3 days of regular temps and it finishes your beer out in commercial time. POW, and just like that you as a homebrewer can have commercial grade temperature control. All I need now is a bright tank, but that would be just silly!

And if you haven't seen this thread yet, it will really blow your mind: https://www.homebrewtalk.com/f258/stc-1000-a-464348/

I slowly ramp up to about 72 after the initial 3 days of regular temps and it finishes your beer out in commercial time. POW, and just like that you as a homebrewer can have commercial grade temperature control. All I need now is a bright tank, but that would be just silly!

I made my own using a roll of flex watt (like this: http://www.ebay.com/itm/Flex-Watt-H...t=LH_DefaultDomain_0&var=&hash=item35c3f874f0) that I cut down do the sizes I needed. I used the 7" so it would fit in between the ridges of the keg easier. I think I used 3' for each? No issues with the jacket, I actually use it to hold my flexwatt on by wrapping it on the outside of it and velcroing the whole thing together.

And if you haven't seen this thread yet, it will really blow your mind: https://www.homebrewtalk.com/f258/stc-1000-a-464348/

I slowly ramp up to about 72 after the initial 3 days of regular temps and it finishes your beer out in commercial time. POW, and just like that you as a homebrewer can have commercial grade temperature control. All I need now is a bright tank, but that would be just silly!

Yea I saw that thread. I have three of those STC-1000, but didn't feel like trying to flash the firmware on those. I also have one of the https://brewbit.com which work great.

parkerhd36

Well-Known Member

I would love to see some pics of any completed panels. Im about to start drilling the front of mine and would like to see what directions some of you have went with it.

I would love to see some pics of any completed panels. Im about to start drilling the front of mine and would like to see what directions some of you have went with it.

Here is one. I cheated and had a friend with a body shop and plasma cutter make all the holes for me. He painted it too at cost!

Go Spartans!

TD

$10.99 ($31.16 / Ounce)

Hornindal Kveik Yeast for Homebrewing - Mead, Cider, Wine, Beer - 10g Packet - Saccharomyces Cerevisiae - Sold by Shadowhive.com

Shadowhive

$20.94

$29.99

The Brew Your Own Big Book of Clone Recipes: Featuring 300 Homebrew Recipes from Your Favorite Breweries

Amazon.com

$53.24

1pc Hose Barb/MFL 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304(Gas MFL)

yunchengshiyanhuqucuichendianzishangwuyouxiangongsi

$53.24

1pc Hose Barb/MFL 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304(Gas MFL)

Guangshui Weilu You Trading Co., Ltd

$176.97

1pc Commercial Keg Manifold 2" Tri Clamp,Ball Lock Tapping Head,Pressure Gauge/Adjustable PRV for Kegging,Fermentation Control

hanhanbaihuoxiaoshoudian

$58.16

HUIZHUGS Brewing Equipment Keg Ball Lock Faucet 30cm Reinforced Silicone Hose Secondary Fermentation Homebrew Kegging Brewing Equipment

xiangshuizhenzhanglingfengshop

$22.00 ($623.23 / Ounce)

AMZLMPKNTW Ball Lock Sample Faucet 30cm Reinforced Silicone Hose Secondary Fermentation Homebrew Kegging joyful

无为中南商贸有限公司

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)

$6.95 ($17.38 / Ounce)

$7.47 ($18.68 / Ounce)

Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]

Hobby Homebrew

$7.79 ($7.79 / Count)

Craft A Brew - LalBrew Voss™ - Kveik Ale Yeast - For Craft Lagers - Ingredients for Home Brewing - Beer Making Supplies - (1 Pack)

Craft a Brew

$479.00

$559.00

EdgeStar KC1000SS Craft Brew Kegerator for 1/6 Barrel and Cornelius Kegs

Amazon.com

$39.22 ($39.22 / Count)

Brewer's Best Home Brew Beer Ingredient Kit - 5 Gallon (Mexican Cerveza)

Amazon.com

$33.99 ($17.00 / Count)

$41.99 ($21.00 / Count)

2 Pack 1 Gallon Large Fermentation Jars with 3 Airlocks and 2 SCREW Lids(100% Airtight Heavy Duty Lid w Silicone) - Wide Mouth Glass Jars w Scale Mark - Pickle Jars for Sauerkraut, Sourdough Starter

Qianfenie Direct

Yeesh!! Blurry!!! I shot another set of photos but the miraculous iPhone hasn't caught up with reality yet so I can't post it from my laptop.....

swanronson

Member

- Joined

- Sep 18, 2013

- Messages

- 13

- Reaction score

- 0

You know Tricky....I do feel quite bad for you...

You know Tricky....I do feel quite bad for you...

Yeah. Bad game against buckeyes dashed any playoff hopes. Oh well. Maybe next year...

swanronson

Member

- Joined

- Sep 18, 2013

- Messages

- 13

- Reaction score

- 0

Yeah. Bad game against buckeyes dashed any playoff hopes. Oh well. Maybe next year...

Yeah, but at least you will make it to a bowl game. Those of us just a touch south of East Landfill wont even make that. Though at least we don't have to wait until the new year to start the coach search lol

Last edited:

swanronson

Member

- Joined

- Sep 18, 2013

- Messages

- 13

- Reaction score

- 0

It appears OSCSYS no longer sells the 8-channel driver boards, like not even listed on their website. I need a back up; anyone have any ideas where to pick one up?

You could try to operate without the driver board. I do believe that it is only a simple amplifier, though I am unsure if it is a voltage, amperage, or power amplifier. I think the reason for it being needed was that the BCS could not operate more than one ball valve at the same time?? If you are only going to run one fermentation at a time, I would give it a whirl without the driver board.

At any rate, if you have any basic skills, you could build your own driver board IF you knew the circuit diagram and type of transistors used on the original design. You might ask OCSYS if they would be willing to send you a circuit diagram and tell you the specs on the solid state components.

From there you could buy parts at radio shack, either with an etched board or a breadboard type.

Alternately, you could simply build your own power amplifier. I do suspect the board is a power amplifier (amplifies both current and voltage). Lastly, you could tap the power supply which should have more than sufficient ability to operate all three valves at once, and design a SSR circuit controlled by the BCS, as is already done with the pumps, but with low voltage, low wattage DC SSRs wired to the BCS output, switching power from the dc power supply to the ball valves.

Really I think any of those options would work. The SSR would likely be the simplest.

TD

At any rate, if you have any basic skills, you could build your own driver board IF you knew the circuit diagram and type of transistors used on the original design. You might ask OCSYS if they would be willing to send you a circuit diagram and tell you the specs on the solid state components.

From there you could buy parts at radio shack, either with an etched board or a breadboard type.

Alternately, you could simply build your own power amplifier. I do suspect the board is a power amplifier (amplifies both current and voltage). Lastly, you could tap the power supply which should have more than sufficient ability to operate all three valves at once, and design a SSR circuit controlled by the BCS, as is already done with the pumps, but with low voltage, low wattage DC SSRs wired to the BCS output, switching power from the dc power supply to the ball valves.

Really I think any of those options would work. The SSR would likely be the simplest.

TD

boat_eggs

Well-Known Member

Has anyone who built one of these setups that used the hydraulic disconnects end up having corrosion on the steel disconnects? Im wondering if I should go brass or steel

I have noticed that there is some tarnishing on the hydraulic QD's. They can polish right up though - so far. The PEG solution I'm using, food grade, is pre-diluted and has blue tint for leak detection and also has anti-corrosive additives.

I'm researching the move to Stainless Conicals that I could adapt to fit the lids with the same coils. I'm not sure if the compression fittings for the coils can be re-used though.

TD

I'm researching the move to Stainless Conicals that I could adapt to fit the lids with the same coils. I'm not sure if the compression fittings for the coils can be re-used though.

TD

boat_eggs

Well-Known Member

Im sure the compression fittings can be reused, might need to replace the internal collar though. I had to search for this but I mentioned that I was awaiting some of the BruGear fermentors and you were the one who expressed interest in them. I finally got them and they seem good so far however I have only dressed them up. If you want some pictures I can send them.

Im sure the compression fittings can be reused, might need to replace the internal collar though. I had to search for this but I mentioned that I was awaiting some of the BruGear fermentors and you were the one who expressed interest in them. I finally got them and they seem good so far however I have only dressed them up. If you want some pictures I can send them.

You bet!! Especially pics of the lid, and the racking arm. What size did you buy?

I would like something easy to adapt to my setup with the coolant coils through the lid. I might need to find a sanitary welder but if I can do wellness all the better.

What's the overall diameter? My holes in the deck are 19" may need to fashion some collars or have legs bent. Are those legs welded?

Thanks

TD

Has anyone who built one of these setups that used the hydraulic disconnects end up having corrosion on the steel disconnects? Im wondering if I should go brass or steel

I've have 3 plastic conicals working based on this design for a year now. I use hydraulic quick disconnects to connect the glycol lines to the coil. Worked well for a while, but now all 6 of them are rusted and basically useless. If I take one off, the fluid comes out so there's no longer a 'dry' disconnect.

I've been using RV antifreeze since day one. I'm thinking that maybe not using the better PG with inhibitors in it might be the source of my issue.

Still haven't applied that weatherstrip to get airtight seal. Been too busy. I am wondering if I might want to go stainless. Trying to think of a way to get a sanitary mount for the coil on the lid that is also removable.

The new FTSS product by the company that makes that stainless steel brewbucket seems to have a valid concept that I am going to try to copy. Need to get a detailed look at it.

TD

The new FTSS product by the company that makes that stainless steel brewbucket seems to have a valid concept that I am going to try to copy. Need to get a detailed look at it.

TD

lazarwolf

Well-Known Member

Can you update this project. It's awesome

Well, the OP seems to be defunct on HBT, I think he moved or something.

What updates did you want? Still using the system. Still not airtight. Minor corrosion on the hydraulic QDS some folks are getting. I think that if you make the hoses connecting the lids to the ball valves and manifold long enough, such that you could close the lid and just leave the coolant lines attached, that the QDs could be eliminated. The pressure lock issue would also be eliminated (when there is cold coolant inside the stainless coil and the QDs are disconnected it is a sealed system, and as the coolant warms it wil lock up the QD so you cannot get them re connected. ).

Lid sealing is problematic. Long term sanitization is still a question I have given the lip on the conical tops, and the lack of internal sanitary fittings and the threaded NPT nipples for instance. I have several beers on tap that taste great from these conicals. I split into two kegs (10G batches) and will see if the second keg (at room temp) is sour or funky when I tap. So far though, so good.

I think to do it again, I might consider using stainless conicals wrapped tightly with a copper coil then insulated and just run the glycol on the outside similar to jacketed conicals.

The FTSS system looks pretty slick too..

TD

What updates did you want? Still using the system. Still not airtight. Minor corrosion on the hydraulic QDS some folks are getting. I think that if you make the hoses connecting the lids to the ball valves and manifold long enough, such that you could close the lid and just leave the coolant lines attached, that the QDs could be eliminated. The pressure lock issue would also be eliminated (when there is cold coolant inside the stainless coil and the QDs are disconnected it is a sealed system, and as the coolant warms it wil lock up the QD so you cannot get them re connected. ).

Lid sealing is problematic. Long term sanitization is still a question I have given the lip on the conical tops, and the lack of internal sanitary fittings and the threaded NPT nipples for instance. I have several beers on tap that taste great from these conicals. I split into two kegs (10G batches) and will see if the second keg (at room temp) is sour or funky when I tap. So far though, so good.

I think to do it again, I might consider using stainless conicals wrapped tightly with a copper coil then insulated and just run the glycol on the outside similar to jacketed conicals.

The FTSS system looks pretty slick too..

TD

- Joined

- Oct 25, 2008

- Messages

- 146

- Reaction score

- 22

Has anyone who built one of these setups that used the hydraulic disconnects end up having corrosion on the steel disconnects? Im wondering if I should go brass or steel

I recently took mine apart while changing the lid and the inside is definitely corroded. I lubed it to getting it moving smooth again, but I am not sure how long it will last.

- Joined

- Oct 25, 2008

- Messages

- 146

- Reaction score

- 22

I had a batch foam over and came out funky (vegetable). I decided to go to the poly carbonate lid that was used earlier in this thread. As I was disassembling the old lid, I found that there was stuff behind the silicon that was supposed to seal the cavity behind the stock lid collar. In general, the silicon is not adhered real well to the conical plastic. I highly recommend that anyone doing this project to go with the bolted on lid solution. I have not fully achieved air tight yet, but I am going to change my feed thru's for the coils and then I think I will be there.

Yeah, I did a brown ale - kegged half, and racked the other half to a freshly sanitized carboy. Within a week, the carboy developed a pellicle. Of two other beers I kegged done in the same time-frame, I put half on tap after chilling and carbonation immediately the other two kegs are at room temp but lids were seated with 45psi CO2. I'm planning to dose those kegs with sugar and transfer to bottles using the keg and beer gun as a bottling bucket and let them bottle condition. It will be interesting to see if they have developed a pellice when I open the lids. Of the ones that I've force carbonated and chilled, no taste of any infection so far and its been about 4 weeks.... I think ultimately my plans for these plastic conicals is to migrate to SS. I'm looking for the easiest path to adapt my equipment.

TD

TD

boat_eggs

Well-Known Member

Im going to start a build thread soon as I have learned much from this one and is my inspiration but I am going in a slightly different direction (stainless conicals from Brugear along with more on the cleaning system among some other things).

But I thought others might gain from where I searched long and hard.

http://www.fremontindustrialsupply.com/

Those guys sell brass quick disconnects with stainless poppets at a decent price IF you buy a multipack. I bought a 10 pack set which was more than I will need after rethinking the design, duh! But it was still less cash than buying individually and brass does not rust.

But I thought others might gain from where I searched long and hard.

http://www.fremontindustrialsupply.com/

Those guys sell brass quick disconnects with stainless poppets at a decent price IF you buy a multipack. I bought a 10 pack set which was more than I will need after rethinking the design, duh! But it was still less cash than buying individually and brass does not rust.

I had a batch foam over and came out funky (vegetable). I decided to go to the poly carbonate lid that was used earlier in this thread. As I was disassembling the old lid, I found that there was stuff behind the silicon that was supposed to seal the cavity behind the stock lid collar. In general, the silicon is not adhered real well to the conical plastic. I highly recommend that anyone doing this project to go with the bolted on lid solution. I have not fully achieved air tight yet, but I am going to change my feed thru's for the coils and then I think I will be there.

I am definitely interested in your feed-through plans. Keep us posted on your system please.

I am not 100% certain that my beers are getting "infected" or not with these concials. Since I do 10 gallons, I'll typically let half sit a room temp is sealed (w/ fully seated lids) kegs, while the other half goes into serving fridge to force carb.

I'm planning to switch to stainless, but waiting to hear about the specifics of the particular concials I'll be switching to. Might end up being blichman actually. been trying to discuss with the Bru-Gear folks, and had been progressing well until they seemed to have dropped off the face of the planet.

My unique cart is part of the reason its taking a while to choose . Thw way the plastic tanks fit exactly into the large holes cut into the diamond plate aluminum is slick, but there don't seem to be any stainless tanks that this would work for without some further modification. Would be painful to swap off the top piece of diamond plate, primarily because I'd need to purge all the glycol, and remove some of the through-the-deck plumbing - I don't even want to think about it in fact...

I'm keenly interested is seeing some detailed photos of how the Stainless Works folks making the FTSS and SS Brewbucket products are doing the through the lid fittings for their cooling coil. I've seen low rez pics but this isn't enough detail to figure it out for me. Seems that would be the way to achieve air-tight and sanitary fittings inside the tanks, AND be able to remove them.

I do not believe the hydraulic fittings are all that great. Mine have a bit of discoloration on them, but mostly seem to buff out with a towel, leaving just a tarnish. The pressure lock from expanding coolant as it warms up is more problematic however.

TD

Well. first snag.

I upgraded to new firmware which permits programmable temp ramping. Pretty cool for fermentations.

Supposedly migrated the old settings, but not completely. I didn't figure that out before I had a fermenter full of wort. took me all night to work out and turns out I was also combating a hardware problem - the darn AC wouldn't cycle the compressor on.... no clue why. I fiddled a bunch with the mechanical knob and viola, its working again. Talk about an aggravating night...

In other news. You really do need the set screws to hold the plastic collars in place on the fermenters or else they will tear the silicone seal. this happened tonight. Need to repair.

Yippee.

TD

I upgraded to new firmware which permits programmable temp ramping. Pretty cool for fermentations.

Supposedly migrated the old settings, but not completely. I didn't figure that out before I had a fermenter full of wort. took me all night to work out and turns out I was also combating a hardware problem - the darn AC wouldn't cycle the compressor on.... no clue why. I fiddled a bunch with the mechanical knob and viola, its working again. Talk about an aggravating night...

In other news. You really do need the set screws to hold the plastic collars in place on the fermenters or else they will tear the silicone seal. this happened tonight. Need to repair.

Yippee.

TD

Sounds like you may have a loose wire between the knob and the start capacitor, or the switch in the knob is going bad. On mine I bypassed the switch and hot wired it together so when it gets power it starts and runs until the power gets cut. (running it off of a stc-1000) Technically that probably isn't correct and may or may not shorten the life of my $40 ac unit by not running the hot side fan for a while after the compressor kicks off, but...

Well mine had been off for a while. ONce it finally decided to start working again, all is fine.

Thinking about swapping over to Blichmann SS. the diameter is near perfect fit for my stand.

Edit-Also, I think I have a better solution for the through the lid coil with a stainless concial.

Need to find a welder. I know a couple guys but not sure if they can do sanitary welding. Frankly not sure if it is critical or not. Could heat sterilize the welds during cleaning with a torch...

Thinking about swapping over to Blichmann SS. the diameter is near perfect fit for my stand.

Edit-Also, I think I have a better solution for the through the lid coil with a stainless concial.

Need to find a welder. I know a couple guys but not sure if they can do sanitary welding. Frankly not sure if it is critical or not. Could heat sterilize the welds during cleaning with a torch...

bellinmi88

Well-Known Member

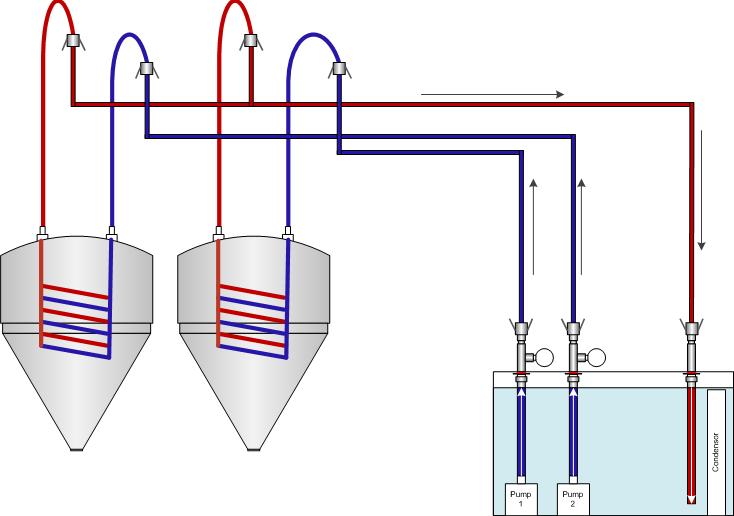

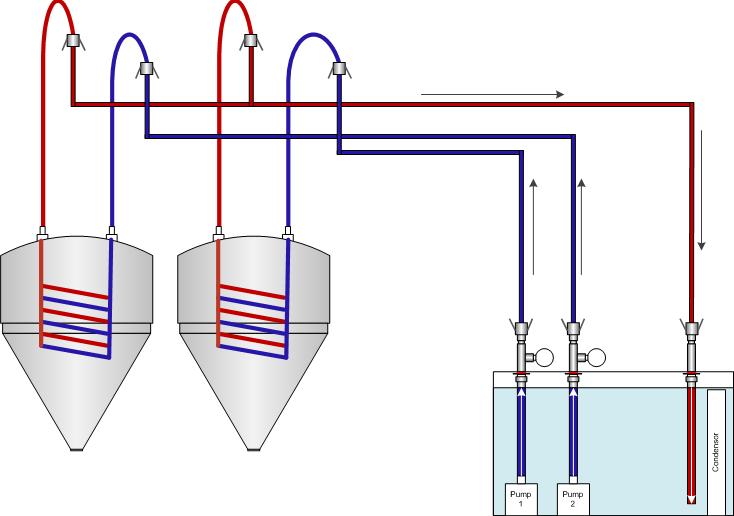

I am sure this has been tried or asked before, but I am going to ask anyway. WILL THIS WORK and IF NOT, WHY?

Shockerengr

Well-Known Member

- Joined

- Feb 22, 2007

- Messages

- 469

- Reaction score

- 34

you'll want a check valve after the pump, or make the return much larger than the supply.I am sure this has been tried or asked before, but I am going to ask anyway. WILL THIS WORK and IF NOT, WHY?

Other wise you may have some of the flow run back through the second tank and chill below your set point.

Also, put the return on the other side of the evaporator to get more flow across it.

Similar threads

- Replies

- 9

- Views

- 2K

- Replies

- 2

- Views

- 1K

Latest posts

-

-

-

-

-

-

Racking wort on to yeast cake that had gelatin with it.

- Latest: Gunshowgreg

-