You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

DIY glycol chilled plastic conical fermenters

- Thread starter packet

- Start date

Help Support Homebrew Talk:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

http://www.teensypi.com/Got a link to his raspberrypi build?

starman

Well-Known Member

Here's the HBT thread.

https://www.homebrewtalk.com/f51/teensypi-networked-temperature-controller-375635/

Its still fairly involved to set up but Jimmy has been supporting it fairly well.

BadWolfBrewing

Well-Known Member

I have a request. When it is all done, please take some pics of the whole brewery / fermentation system together. I'd like something to stare at wistfully while saving my nickels...

Nice work, it looks great so far, an inspiring build. I finally found a mini-fridge that will fit an ale pale without any modification, hopefully that will hold me over for the couple of years it will take for me to win the powerball.

Nice work, it looks great so far, an inspiring build. I finally found a mini-fridge that will fit an ale pale without any modification, hopefully that will hold me over for the couple of years it will take for me to win the powerball.

I have a request. When it is all done, please take some pics of the whole brewery / fermentation system together. I'd like something to stare at wistfully while saving my nickels...

Nice work, it looks great so far, an inspiring build. I finally found a mini-fridge that will fit an ale pale without any modification, hopefully that will hold me over for the couple of years it will take for me to win the powerball.

Sure. The brewery is in a bit of a state of flux right now though. I'm in the middle of transitioning everything over to tri-clover fittings.

$20.94

$29.99

The Brew Your Own Big Book of Clone Recipes: Featuring 300 Homebrew Recipes from Your Favorite Breweries

Amazon.com

$33.99 ($17.00 / Count)

$41.99 ($21.00 / Count)

2 Pack 1 Gallon Large Fermentation Jars with 3 Airlocks and 2 SCREW Lids(100% Airtight Heavy Duty Lid w Silicone) - Wide Mouth Glass Jars w Scale Mark - Pickle Jars for Sauerkraut, Sourdough Starter

Qianfenie Direct

$7.79 ($7.79 / Count)

Craft A Brew - LalBrew Voss™ - Kveik Ale Yeast - For Craft Lagers - Ingredients for Home Brewing - Beer Making Supplies - (1 Pack)

Craft a Brew

$39.22 ($39.22 / Count)

Brewer's Best Home Brew Beer Ingredient Kit - 5 Gallon (Mexican Cerveza)

Amazon.com

$53.24

1pc Hose Barb/MFL 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304(Gas MFL)

Guangshui Weilu You Trading Co., Ltd

$10.99 ($31.16 / Ounce)

Hornindal Kveik Yeast for Homebrewing - Mead, Cider, Wine, Beer - 10g Packet - Saccharomyces Cerevisiae - Sold by Shadowhive.com

Shadowhive

$53.24

1pc Hose Barb/MFL 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304(Gas MFL)

yunchengshiyanhuqucuichendianzishangwuyouxiangongsi

$176.97

1pc Commercial Keg Manifold 2" Tri Clamp,Ball Lock Tapping Head,Pressure Gauge/Adjustable PRV for Kegging,Fermentation Control

hanhanbaihuoxiaoshoudian

$22.00 ($623.23 / Ounce)

AMZLMPKNTW Ball Lock Sample Faucet 30cm Reinforced Silicone Hose Secondary Fermentation Homebrew Kegging joyful

无为中南商贸有限公司

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)

$6.95 ($17.38 / Ounce)

$7.47 ($18.68 / Ounce)

Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]

Hobby Homebrew

$479.00

$559.00

EdgeStar KC1000SS Craft Brew Kegerator for 1/6 Barrel and Cornelius Kegs

Amazon.com

$58.16

HUIZHUGS Brewing Equipment Keg Ball Lock Faucet 30cm Reinforced Silicone Hose Secondary Fermentation Homebrew Kegging Brewing Equipment

xiangshuizhenzhanglingfengshop

Carlscan26

Well-Known Member

packet said:Quick disconnects showed up today:

What type are those?

What type are those?

ISO 7241-B. Usually used for hydraulics, but they more than meet the temp and flow requirements for the glycol.

Spray Ball:

I also hooked up the fittings for the blow off tubing while I wait for the tri-clover fittings to show up.

The bad news is that it appears one of the three motorized ball valves isn't working. I was testing them via the BCS and the one on Ferm 3 moved slightly once and then quit. So, bad news there. I ordered another 3 to have spares on hand, but it'll probably take a couple weeks to get here from China.

I also hooked up the fittings for the blow off tubing while I wait for the tri-clover fittings to show up.

The bad news is that it appears one of the three motorized ball valves isn't working. I was testing them via the BCS and the one on Ferm 3 moved slightly once and then quit. So, bad news there. I ordered another 3 to have spares on hand, but it'll probably take a couple weeks to get here from China.

starman

Well-Known Member

Its more pex tubing but do you think a submersible fountain pump for each conical would be easier to manage? There's one less SSR and you don't need to pump that much volume.

Its more pex tubing but do you think a submersible fountain pump for each conical would be easier to manage? There's one less SSR and you don't need to pump that much volume.

You could, but that would actually add 2 SSRs. The ball valves are driven directly off a 12v driver board (https://www.oscsys.com/store/product/1002030). So, no SSR needed for those. Also, the pump takes up a decent amount of volume in the cooler (https://lh6.googleusercontent.com/-...AAAAAy4/JklD-1CEjlw/w800-h533-no/IMG_3318.jpg). Although I guess you could go with smaller pumps if you're going with one per conical.

The other thing I liked about the single pump design is that I can turn the pump on when just the chiller runs to circulate the water in the cooler, which is handy.

6 of one, half a dozen of another though. One pump per conical would probably work fairly well, but it would cost you a couple of additional ball valves and pressure gauges.

If it's not one thing, it's another. It appears that the bad ball valve took 3 channels of the driver board with it. So, I'll need another one of those. Hopefully OSC will get them in stock again soon.

I remember seeing a thread for one pop up on the for sale forum today (don't know if it had been sold or not though)

https://www.homebrewtalk.com/f16/12v-16-channel-relay-board-415897/

Plus some ball valves from the same guy https://www.homebrewtalk.com/f16/1-2-stainless-motorized-ball-valves-415882/

starman

Well-Known Member

Ah gotcha on the SSR count - had it in my head those were 120v AC valves.

I was thinking of using the submersible fountain pumps that do ~150gph with a short amount of lift and are relatively small, 2"x3"x3" They leach heat so the more they run the greater the load on the AC. I'll be curious how many gph it takes to keep your conicals happy at different temperature deltas.

Hope you get it the replacements soon and are operational quickly.

I was thinking of using the submersible fountain pumps that do ~150gph with a short amount of lift and are relatively small, 2"x3"x3" They leach heat so the more they run the greater the load on the AC. I'll be curious how many gph it takes to keep your conicals happy at different temperature deltas.

Hope you get it the replacements soon and are operational quickly.

Ah gotcha on the SSR count - had it in my head those were 120v AC valves.

I was thinking of using the submersible fountain pumps that do ~150gph with a short amount of lift and are relatively small, 2"x3"x3" They leach heat so the more they run the greater the load on the AC. I'll be curious how many gph it takes to keep your conicals happy at different temperature deltas.

Hope you get it the replacements soon and are operational quickly.

The pump I have is a 1/4 horsepower submersible pump usually used for draining small pools. ~$45 on amazon. I have a ball valve to control flow and a pressure gauge on the line to control the line pressure. So, hopefully it'll work pretty well. If I need something smaller I plan on using the pump for the spray ball to clean the conicals later on.

Like I said before, three pumps would probably work. My main concern is that's a lot of tubing to run out of the cooler and could get messy pretty quickly.

BadWolfBrewing

Well-Known Member

is there any limitation on CIP in a plastic conical? I've never tried CIP before (sounds awesome though), but I thought the CIP chemicals were too potent for anything but stainless.

is there any limitation on CIP in a plastic conical? I've never tried CIP before (sounds awesome though), but I thought the CIP chemicals were too potent for anything but stainless.

I wouldn't try any of the strong acid washes. I plan on using PBW, which others have used without an issue. I just didn't want to deal with 15-20 gallons of it at a time. So, I'm going to try using a spray ball.

ClaudiusB

Well-Known Member

is there any limitation on CIP in a plastic conical? I've never tried CIP before (sounds awesome though), but I thought the CIP chemicals were too potent for anything but stainless.

Look up the compatibility chart for the plastic and chemical you are planning to use.

Example below.

http://www.coleparmer.com/Chemical-Resistance

Cheers,

ClaudiusB

I use PBW and a spray ball.....works quite well. You still need to do poke your hand and sponge in there cause there are some nooks and crannys the spray doesn't get too.

I use PBW and a spray ball.....works quite well. You still need to do poke your hand and sponge in there cause there are some nooks and crannys the spray doesn't get too.

Yeah, the main thing I don't like about the conicals is that the screws for the lid go all the way through the plastic. Thankfully beer shouldn't ever get that high though.

All in all, it should be pretty easy to clean.

Just curious on your thoughts. I currently ferment in my basement, so that is where the conical would go. I do all of my brewing in my garage. Do you think it would be a good idea to drain my brew kettle into two 6 gallon buckets, carry those down stairs, and then dump them into the conical?

smakudwn

Well-Known Member

Just curious on your thoughts. I currently ferment in my basement, so that is where the conical would go. I do all of my brewing in my garage. Do you think it would be a good idea to drain my brew kettle into two 6 gallon buckets, carry those down stairs, and then dump them into the conical?

I have been thinking about this too. I even had a crazy idea of running a hose from the brewkettle to the basement..........

- Joined

- May 6, 2013

- Messages

- 14,033

- Reaction score

- 3,378

that seems like the more sane option is you ask me haha buckets wouldnt be bad except for the extra work and extra chance of a brew day disaster!

That's exactly what I do. Two buckets. I've contemplated the 30' hose.......it would be a nuisance to clean and sanitize I think.

I'd stick with buckets. Much less hassle to clean/sanitize than a 30 ft hose. On the plus side, it'll be a lot easier to keg the beer from a conical instead of a carboy. No need for racking canes anymore.

As it is I brew in the garage and don't have a water line out there. So, I carry 5 gal buckets of water to brew with. It's a bit of a pain, but I had no extra room for a sink.

As it is I brew in the garage and don't have a water line out there. So, I carry 5 gal buckets of water to brew with. It's a bit of a pain, but I had no extra room for a sink.

barryfine

Well-Known Member

I'd stick with buckets. Much less hassle to clean/sanitize than a 30 ft hose. On the plus side, it'll be a lot easier to keg the beer from a conical instead of a carboy. No need for racking canes anymore.

As it is I brew in the garage and don't have a water line out there. So, I carry 5 gal buckets of water to brew with. It's a bit of a pain, but I had no extra room for a sink.

I brew in a detached garage as well. I just run a long drinking water safe hose to the garage on brew day. I just roll it up on a roller with wheels when I'm done with it after draining it. I usually just blast CO2 through the hose to push out all of the water. It's a pain, but it's better than carrying a bunch of buckets to the garage.

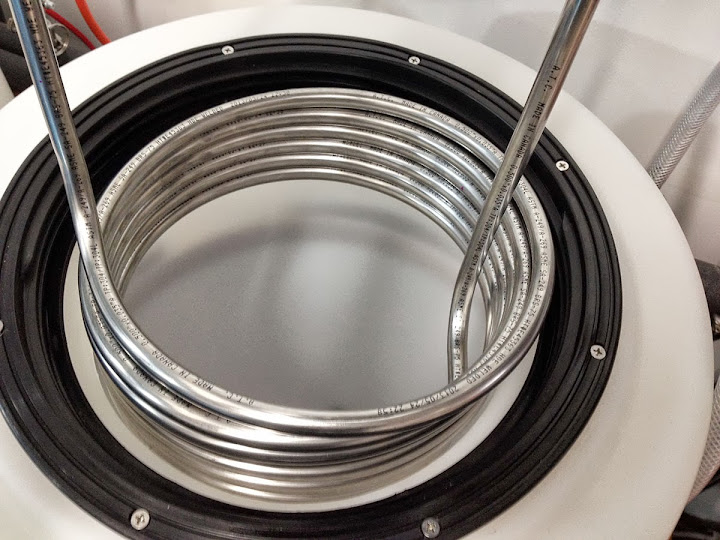

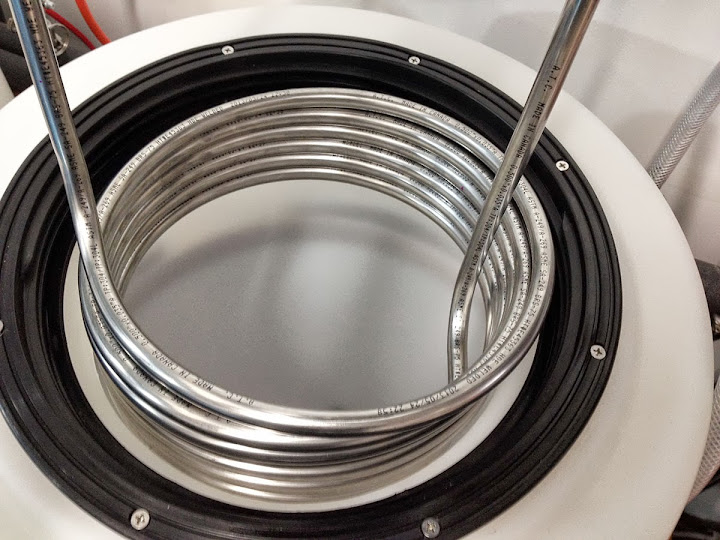

Thermowell in place:

Thank god this fit. Just barely makes it through the lid:

Quick disconnects in place on the lid:

Still need the tri-clover connection for the blow off tube in the center fitting, but those will hopefully ship soon.

Now I just need to finish connecting the fittings on the other two conicals...

Thank god this fit. Just barely makes it through the lid:

Quick disconnects in place on the lid:

Still need the tri-clover connection for the blow off tube in the center fitting, but those will hopefully ship soon.

Now I just need to finish connecting the fittings on the other two conicals...

I brew in a detached garage as well. I just run a long drinking water safe hose to the garage on brew day. I just roll it up on a roller with wheels when I'm done with it after draining it. I usually just blast CO2 through the hose to push out all of the water. It's a pain, but it's better than carrying a bunch of buckets to the garage.

I generally brew with RO water. So, I'm stuck with buckets.

barryfine

Well-Known Member

Gotcha. That's worth the trouble, I suppose. I just use a whole house carbon filter, but it's not nearly as good as RO. I'll sit back and continue to enjoy your build.

I generally brew with RO water. So, I'm stuck with buckets.

And the remaining conical fittings are done:

Now all that's left is the tri-clover blowoff valve fittings and the replacement ball valves. Thankfully the ball valves were shipped from China yesterday. So, hopefully the boat gets here fast.

Now all that's left is the tri-clover blowoff valve fittings and the replacement ball valves. Thankfully the ball valves were shipped from China yesterday. So, hopefully the boat gets here fast.

Similar threads

- Replies

- 9

- Views

- 2K

- Replies

- 2

- Views

- 1K

Latest posts

-

-

Pilsner Malt Comparison: Rahr vs. Weyermann vs. Great Western vs. Viking

- Latest: FranklinsBeerTower

-

-

-