Boerderij_Kabouter

Well-Known Member

[EDIT] This thread used to be titled Brouwerij Boerderij Kabouter and was a build thread for my brewery. I have since sold the test brewery and constructed a small scale electric brewery (see the Simple brewery and 2P-Twent-E). This build is still my dream and I already have my eye on parts collection so I can have a DITCHES of my own in a couple years.

A few DITCHES have shown up and I am currently building a hardplumbed super-bling version now for another HBT member. Below is the full development of the design and several useful thoughts and posts.

Enjoy

[/EDIT]

After many months of thinking drawing, rethinking and redrawing, posting, and listening,.... I think I have my "final" design for my brewery down. It is a single tier two pump system with three direct fire tuns, a HERMS, and a new cooling system (yet to be named).

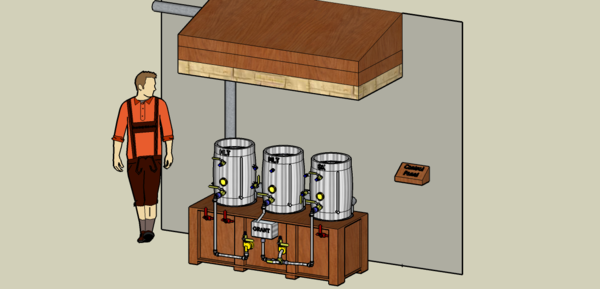

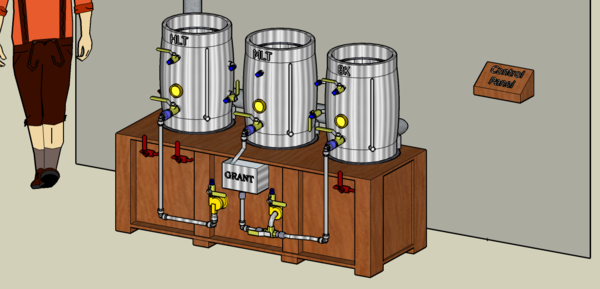

Here is the base layout:

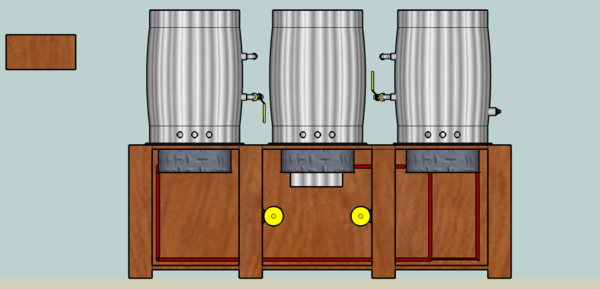

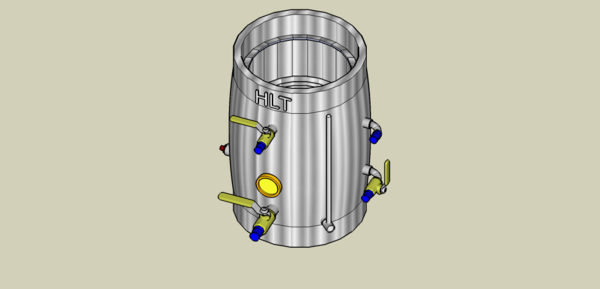

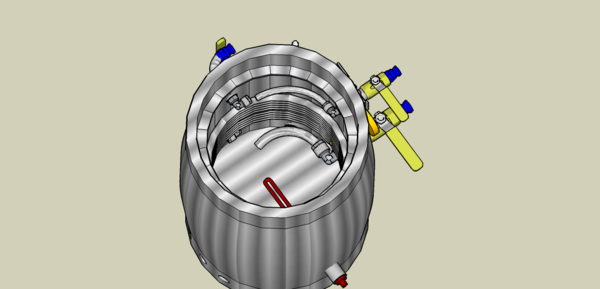

The HLT (left) includes a HERMS coil (stainless) hard mounted into the tun, a copper whirlpool return on the top and a hard mounted outlet at the bottom. The outlet leads to a 809 pump (bronze). I also plan to have an electric heating element with a temperature controller setup for maintaining the temperature within the HLT during the mash. All heating operations will be done with a propane burner.

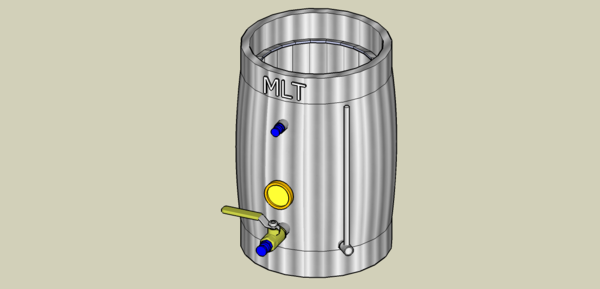

The MLT (middle) includes a stainless false bottom, with stainless pickup, and an adjustable height stainless sparge ring. Steps will be done with a propane burner. The HERMS is only for maintaining temperatures during the mash and clearing the wort.

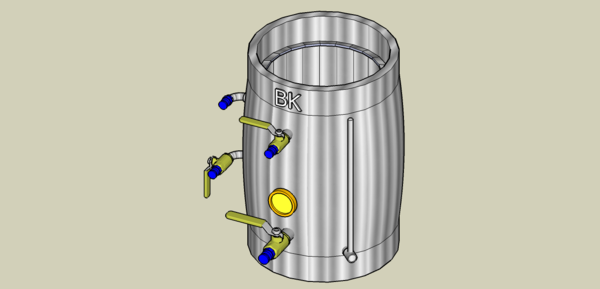

The BK (right) includes a stainless pickup and whirlpool return, and a hard-mounted stainless cooling coil.

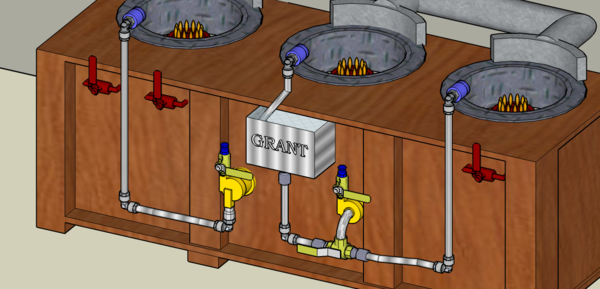

The first pump (left) will be used to transfer water only, and the second pump (right) will be used for wort transfer only.

The three lines at the bottom of the drawing are the hoses that will be used to route the system. All connections will have stainless quick disconnects from B3.

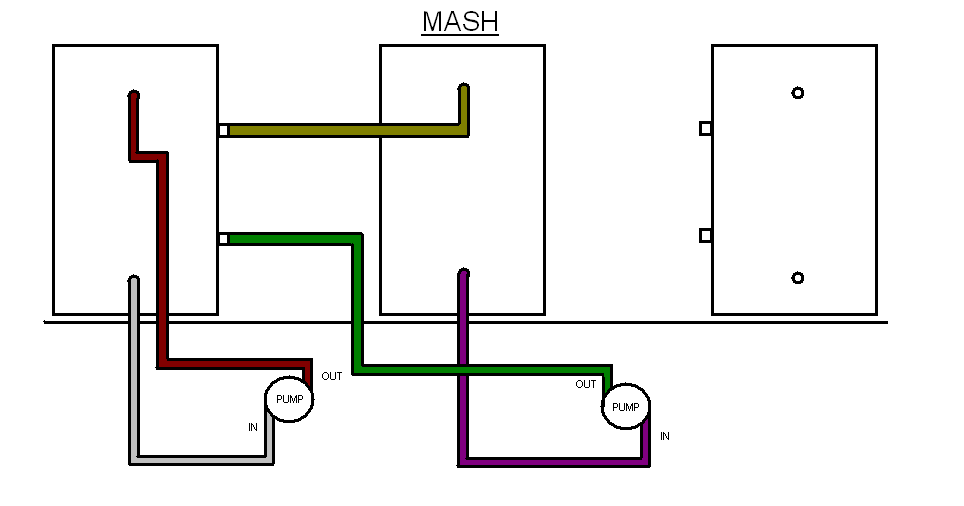

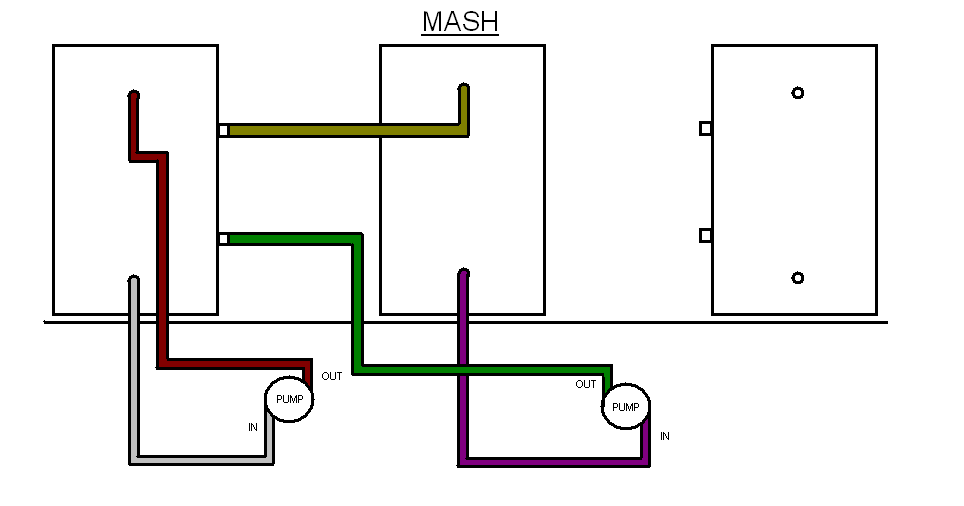

Here is the configuration while mashing:

The first pump will recirculate the HLT water around the HERMS to ensure an even heat distrobution within the HLT. During the mash, the electric heater with add heat back in that is removed by the HERMS.

The second pump will recirculate wort through the HERMS. Step mashes will be done by carefully adding heat with the propane burner.

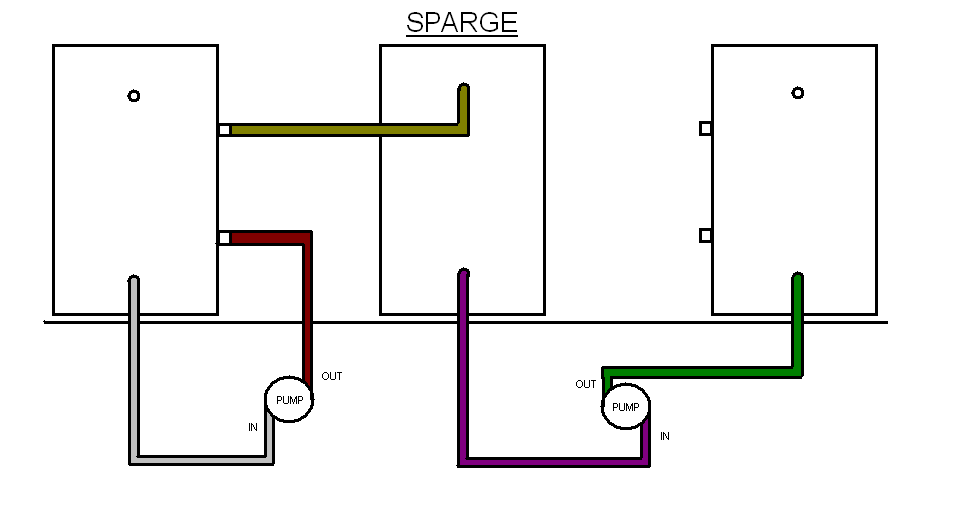

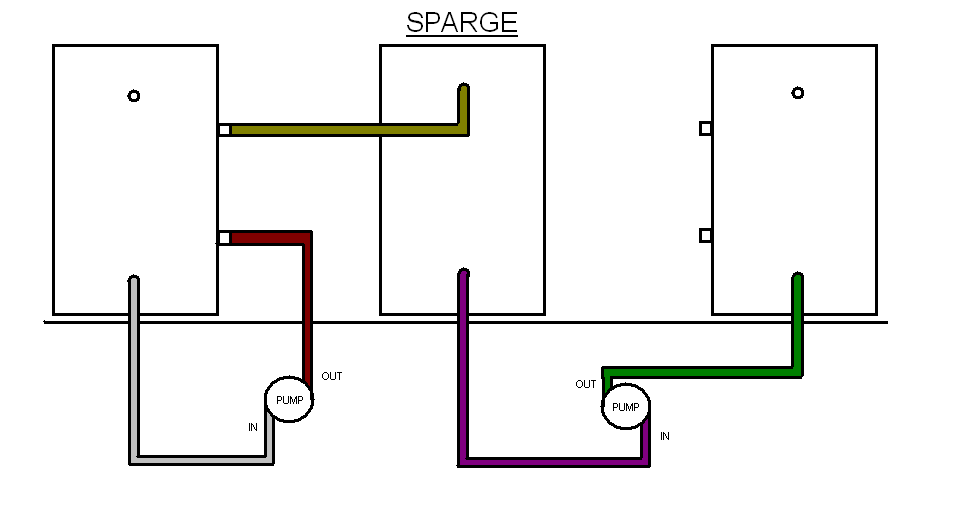

Here is the configuration while sparging:

After the mash, the first pump outlet is routed through the HERMS coil and then into the sparge ring. This should push all the sweet wort remaining in the HERMS out, and into the BK. The output of the second pump will be routed to the BK.

The boil will be standard and manually operated.

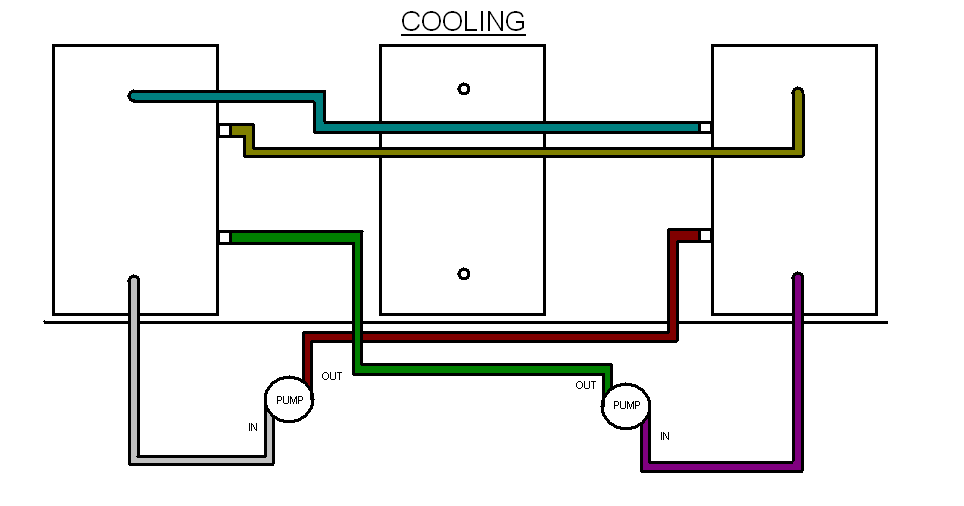

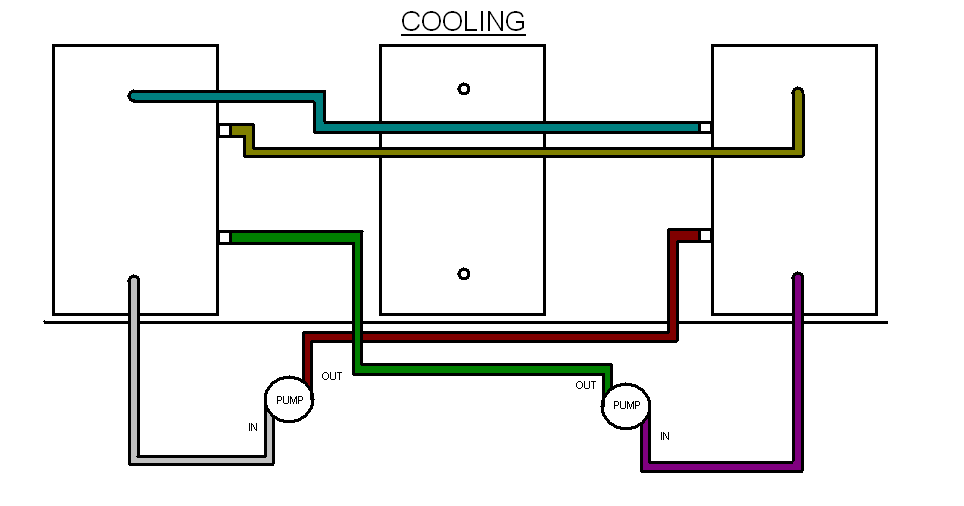

Here is the configuration while cooling:

Here is where my new cooling idea comes in.... the HLT will be filled with ice water during cooling, and the first pump will recirculate the ice water through the cooling coil in the BK while the second pump recirculates wort through the HERMS submerged in ice water. Both returns are setup for whirlpools to ensure trub collection and good heat transfer. I hope this system will be able to chill my full wort volume very quickly.

I have priced this beast out, and from where I stand now I need to raise $500 to get it done. As I complete parts of the build I will post my progress here.

Let me know what you think!

A few DITCHES have shown up and I am currently building a hardplumbed super-bling version now for another HBT member. Below is the full development of the design and several useful thoughts and posts.

Enjoy

[/EDIT]

After many months of thinking drawing, rethinking and redrawing, posting, and listening,.... I think I have my "final" design for my brewery down. It is a single tier two pump system with three direct fire tuns, a HERMS, and a new cooling system (yet to be named).

Here is the base layout:

The HLT (left) includes a HERMS coil (stainless) hard mounted into the tun, a copper whirlpool return on the top and a hard mounted outlet at the bottom. The outlet leads to a 809 pump (bronze). I also plan to have an electric heating element with a temperature controller setup for maintaining the temperature within the HLT during the mash. All heating operations will be done with a propane burner.

The MLT (middle) includes a stainless false bottom, with stainless pickup, and an adjustable height stainless sparge ring. Steps will be done with a propane burner. The HERMS is only for maintaining temperatures during the mash and clearing the wort.

The BK (right) includes a stainless pickup and whirlpool return, and a hard-mounted stainless cooling coil.

The first pump (left) will be used to transfer water only, and the second pump (right) will be used for wort transfer only.

The three lines at the bottom of the drawing are the hoses that will be used to route the system. All connections will have stainless quick disconnects from B3.

Here is the configuration while mashing:

The first pump will recirculate the HLT water around the HERMS to ensure an even heat distrobution within the HLT. During the mash, the electric heater with add heat back in that is removed by the HERMS.

The second pump will recirculate wort through the HERMS. Step mashes will be done by carefully adding heat with the propane burner.

Here is the configuration while sparging:

After the mash, the first pump outlet is routed through the HERMS coil and then into the sparge ring. This should push all the sweet wort remaining in the HERMS out, and into the BK. The output of the second pump will be routed to the BK.

The boil will be standard and manually operated.

Here is the configuration while cooling:

Here is where my new cooling idea comes in.... the HLT will be filled with ice water during cooling, and the first pump will recirculate the ice water through the cooling coil in the BK while the second pump recirculates wort through the HERMS submerged in ice water. Both returns are setup for whirlpools to ensure trub collection and good heat transfer. I hope this system will be able to chill my full wort volume very quickly.

I have priced this beast out, and from where I stand now I need to raise $500 to get it done. As I complete parts of the build I will post my progress here.

Let me know what you think!

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)