I am an all grain brewer that recently switched to distilled water. I add a minimal amount of brewing salts to my water. However my fermentations have been coming up short of the intended FG. I am confident that fermentation temperatures have been good and consistent, sanitation the same. Do I need to add yeast nutrient to my boil to assist my fermentation?

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Distilled water and yeast nutrient

- Thread starter aplogan

- Start date

Help Support Homebrew Talk:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

Distilled water is void of everything yeast want, so yes adding some yeast nutrient may help or take care of your issue. If adding nutrient, get a nutrient that is geared to beer rather than wine. One example is Wyeast yeast nutrient. It contains pretty much all of the vitamins, minerals, sterols, and amino acids the yeast need, love, and want. You many need to add a touch more than directed due to your use of distilled water.

Yeast need nitrogen, vitamins, minerals to multiply, and survive. If there is not enough of what they need, incomplete fermenation is one of many things that can result.

Another thing that can cause incomplete fermentation is lack of oxygen. We all know how to fix that

Yeast need nitrogen, vitamins, minerals to multiply, and survive. If there is not enough of what they need, incomplete fermenation is one of many things that can result.

Another thing that can cause incomplete fermentation is lack of oxygen. We all know how to fix that

Distilled water is void of everything yeast want, so yes adding some yeast nutrient may help or take care of your issue. If adding nutrient, get a nutrient that is geared to beer rather than wine. One example is Wyeast yeast nutrient. It contains pretty much all of the vitamins, minerals, sterols, and amino acids the yeast need, love, and want. You many need to add a touch more than directed due to your use of distilled water.

Yeast need nitrogen, vitamins, minerals to multiply, and survive. If there is not enough of what they need, incomplete fermenation is one of many things that can result.

Another thing that can cause incomplete fermentation is lack of oxygen. We all know how to fix that

Thanks Toga. I aerate with pure 02 approximately .5 to 1 L per minute for 75 seconds. I reviewed some of my old brewing notes and I always been around my target FG 1.012-1.016. I was using my tapwater and on occasion spring water. I went away from the tap water because my pill beers did not taste right. They were dull due to the high HCO3 in my tap water. I learned that if I use distilled water and add mineral salts I can get a better tasting pale beer.

Can I add the yeast nutrient to an already started fermentation? This afternoon will be day two. If so, how would I add it?

Thanks Toga. I aerate with pure 02 approximately .5 to 1 L per minute for 75 seconds. I reviewed some of my old brewing notes and I always been around my target FG 1.012-1.016. I was using my tapwater and on occasion spring water. I went away from the tap water because my pill beers did not taste right. They were dull due to the high HCO3 in my tap water. I learned that if I use distilled water and add mineral salts I can get a better tasting pale beer.

Can I add the yeast nutrient to an already started fermentation? This afternoon will be day two. If so, how would I add it?

Can't say I have ever added nutrient to beer during fermentation. But I have added malt extract to bump gravity with good results. I would dump it in then gently swirl the fermenter a bit or gently stir with a sanitized spoon being careful to not aerate. And do it right away. don't wait.

No, yeast nutrient isn’t typically needed. Distilled water is fine. Malt has plenty of magnesium and everything else needed for a healthy fermentation, except perhaps for zinc. (And you don’t want zinc in the water, anyway).

Are you making large enough starters for the OG? How about mash temperatures? If a beer is underattenuated, it’s usually yeast strain choice, pitching rate, mash temperature, or ingredients (like more dextrin type malts).

Are you making large enough starters for the OG? How about mash temperatures? If a beer is underattenuated, it’s usually yeast strain choice, pitching rate, mash temperature, or ingredients (like more dextrin type malts).

Also, a guy had some off flavors in his beer and so he sent them to me to see if I could figure it out (I’m a BJCP judge).

His beers were really good- but there was indeed something not quite right. Turns out, ALL of his technique was excellent, but he was using yeast nutrient in every single batch. I don’t know the brand or type, but once he left it out and send me a few new beers, they were excellent.

So....before you add it because the beers are underattenuated, check out the other likely issues first.

His beers were really good- but there was indeed something not quite right. Turns out, ALL of his technique was excellent, but he was using yeast nutrient in every single batch. I don’t know the brand or type, but once he left it out and send me a few new beers, they were excellent.

So....before you add it because the beers are underattenuated, check out the other likely issues first.

$176.97

1pc Commercial Keg Manifold 2" Tri Clamp,Ball Lock Tapping Head,Pressure Gauge/Adjustable PRV for Kegging,Fermentation Control

hanhanbaihuoxiaoshoudian

$58.16

HUIZHUGS Brewing Equipment Keg Ball Lock Faucet 30cm Reinforced Silicone Hose Secondary Fermentation Homebrew Kegging Brewing Equipment

xiangshuizhenzhanglingfengshop

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)

$6.95 ($17.38 / Ounce)

$7.47 ($18.68 / Ounce)

Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]

Hobby Homebrew

$39.22 ($39.22 / Count)

Brewer's Best Home Brew Beer Ingredient Kit - 5 Gallon (Mexican Cerveza)

Amazon.com

$20.94

$29.99

The Brew Your Own Big Book of Clone Recipes: Featuring 300 Homebrew Recipes from Your Favorite Breweries

Amazon.com

$172.35

2 Inch Tri Clamp Keg Manifold With Ball Lock Posts, Pressure Gauge, PRV (0-30 PSI) – Homebrew, Fermentation, Kegging System

wuhanshijiayangzhiyimaoyiyouxiangongsi

$27.29 ($13.64 / Count)

$41.99 ($21.00 / Count)

2 Pack 1 Gallon Large Fermentation Jars with 3 Airlocks and 2 SCREW Lids(100% Airtight Heavy Duty Lid w Silicone) - Wide Mouth Glass Jars w Scale Mark - Pickle Jars for Sauerkraut, Sourdough Starter

Qianfenie Direct

$10.99 ($31.16 / Ounce)

Hornindal Kveik Yeast for Homebrewing - Mead, Cider, Wine, Beer - 10g Packet - Saccharomyces Cerevisiae - Sold by Shadowhive.com

Shadowhive

$53.24

1pc Hose Barb/MFL 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304(Liquid Hose Barb)

Guangshui Weilu You Trading Co., Ltd

$33.95

Five Star - 6022b_ - Star San - 32 Ounce - High Foaming Sanitizer

Bridgeview Beer and Wine Supply

$22.00 ($623.23 / Ounce)

AMZLMPKNTW Ball Lock Sample Faucet 30cm Reinforced Silicone Hose Secondary Fermentation Homebrew Kegging joyful

无为中南商贸有限公司

$53.24

1pc Hose Barb/MFL 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304(Liquid Hose Barb)

yunchengshiyanhuqucuichendianzishangwuyouxiangongsi

$7.79 ($7.79 / Count)

Craft A Brew - LalBrew Voss™ - Kveik Ale Yeast - For Craft Lagers - Ingredients for Home Brewing - Beer Making Supplies - (1 Pack)

Craft a Brew

Also, a guy had some off flavors in his beer and so he sent them to me to see if I could figure it out (I’m a BJCP judge).

His beers were really good- but there was indeed something not quite right. Turns out, ALL of his technique was excellent, but he was using yeast nutrient in every single batch. I don’t know the brand or type, but once he left it out and send me a few new beers, they were excellent.

So....before you add it because the beers are underattenuated, check out the other likely issues first.

Thanks Yooper. To your previous thread, I’ve been pitching two packs of US-05 rehydrated. My beers have been 1.08 and 1.063 most recent.

Thanks Yooper. To your previous thread, I’ve been pitching two packs of US-05 rehydrated. My beers have been 1.08 and 1.063 most recent.

Mash temps have been 152 to 155.

OG 1.085. FG 1.030. Should have been 1.022

OG. 1.063. FG 1.020. Should have been 1.014

Also, a guy had some off flavors in his beer and so he sent them to me to see if I could figure it out (I’m a BJCP judge).

His beers were really good- but there was indeed something not quite right. Turns out, ALL of his technique was excellent, but he was using yeast nutrient in every single batch. I don’t know the brand or type, but once he left it out and send me a few new beers, they were excellent.

So....before you add it because the beers are underattenuated, check out the other likely issues first.

Mash temps have been 152 to 155.

OG 1.085. FG 1.030. Should have been 1.022

OG. 1.063. FG 1.020. Should have been 1.014

brewbama

Well-Known Member

- Joined

- Sep 20, 2013

- Messages

- 3,802

- Reaction score

- 2,829

Also, a guy had some off flavors in his beer and so he sent them to me to see if I could figure it out (I’m a BJCP judge).

His beers were really good- but there was indeed something not quite right. Turns out, ALL of his technique was excellent, but he was using yeast nutrient in every single batch. I don’t know the brand or type, but once he left it out and send me a few new beers, they were excellent.

So....before you add it because the beers are underattenuated, check out the other likely issues first.

That’s interesting. I also build from distilled and use nutrient. Though I don’t have any off flavor I can detect, I’ve never heard it can cause off flavors.

Mash temps have been 152 to 155.

OG 1.085. FG 1.030. Should have been 1.022

OG. 1.063. FG 1.020. Should have been 1.014

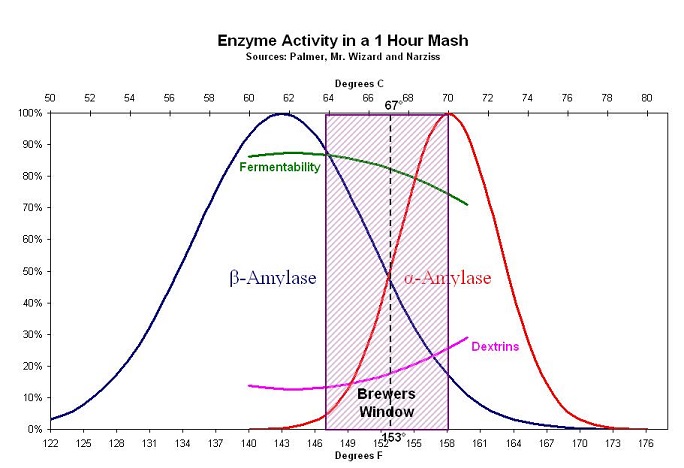

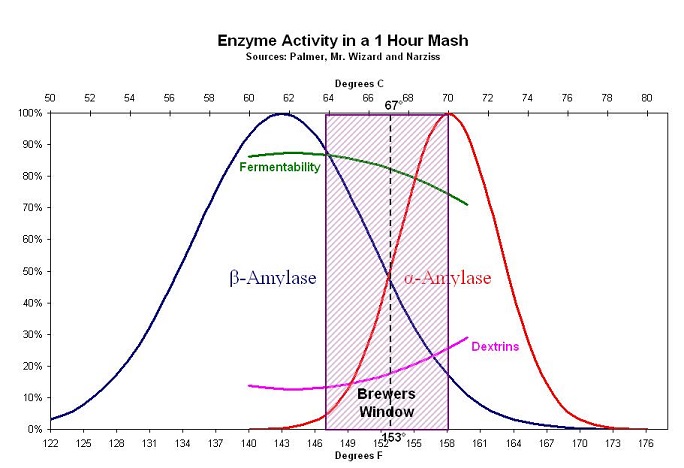

How do you decide what it “should be”? A mash temp of 155 may mean a very high Fg especially if it spent more than 10 minutes there!

How do you decide what it “should be”? A mash temp of 155 may mean a very high Fg especially if it spent more than 10 minutes there!

I get my FG from Beersmith 2.

So...10 mins at 155 can result in a significantly higher FG than for example 60 mins at 152?

Yes. You can actually get full conversion in a very short time at 155.

A higher mash temperature will favor a high FG.

A higher mash temperature will favor a high FG.

Yes. You can actually get full conversion in a very short time at 155.

A higher mash temperature will favor a high FG.

I just switched to a HERMS coil. I pulled a pH sample 35 mins into the mash. I checked for conversion also. After 35 mins I’d converted the starch.

Does this mean that I can shorten my mash to 25 mins if all the starch has been converted at 25 mins? That would really shorten the brew day.

Lefou

Danged rascally furt

- Joined

- May 1, 2016

- Messages

- 2,300

- Reaction score

- 1,228

This is a fairly informative visual of a mashing reference I go by. It's basically an illustration where an optimal range overlap occurs for amylase conversion. I typically do a 90 minute mash between 145F - 152F for drier beers.

Last edited:

Lefou

Danged rascally furt

- Joined

- May 1, 2016

- Messages

- 2,300

- Reaction score

- 1,228

I just switched to a HERMS coil. I pulled a pH sample 35 mins into the mash. I checked for conversion also. After 35 mins I’d converted the starch.

Does this mean that I can shorten my mash to 25 mins if all the starch has been converted at 25 mins? That would really shorten the brew day.

Yes, if you have a highly diastatic mash conversion can happen fairly quickly.

I like to draw things out a bit to get a more fermentable wort - that, and I'm in no hurry to make things happen because I can devote an entire day out of a weekend to sit back and brew.

I just switched to a HERMS coil. I pulled a pH sample 35 mins into the mash. I checked for conversion also. After 35 mins I’d converted the starch.

Does this mean that I can shorten my mash to 25 mins if all the starch has been converted at 25 mins? That would really shorten the brew day.

No, it means that you have converted all the starch to sugars. You may have long chain sugars (dextrines) that the enzymes have not broken down to more fermentable sugars and you may not have extracted all the flavors yet as that takes more time than the conversion. I do a lot of 30 minute mashes but I can only do that because I mill the grains to tiny bits. I have used iodine to test for starch and have compared the final gravity to a normal batch and can have total conversion in less than 10 minutes but I found that that gets me the right OG and FG and flavorless beer.

Similar threads

- Replies

- 2

- Views

- 475

- Replies

- 30

- Views

- 2K

- Replies

- 32

- Views

- 3K

Latest posts

-

-

-

-

-

-

-

I just poured 42 bottles of HB Dunkelweizen down the drain

- Latest: Hoochin'Fool