arturo7

Well-Known Member

Fact or Opinion?

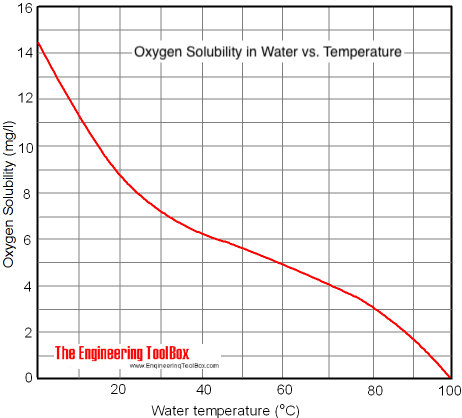

>Dissolved oxygen content of 8-16 PPM is ideal for yeast.

>8 PPM can be acheived with shaking, splashing or forced aeration (aquarium pump with stone).

>8 PPM cannot be exceeded without the use of pure oxygen.

Also, has anyone used one these DO measuring kits?

http://www.coleparmer.com/catalog/product_view.asp?sku=5300300

x

>Dissolved oxygen content of 8-16 PPM is ideal for yeast.

>8 PPM can be acheived with shaking, splashing or forced aeration (aquarium pump with stone).

>8 PPM cannot be exceeded without the use of pure oxygen.

Also, has anyone used one these DO measuring kits?

http://www.coleparmer.com/catalog/product_view.asp?sku=5300300

x

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)