***If anyone has a bottle of 2011 DFH 120 minute, I'll gladly trade you a bottle of mine. PM me***

After sharing a few bottles with some friends over the last week, I'll say I'm very happy with how this turned out. It's very, very, close to 120 minute. There's some citrus in the aroma, mixed with a raisin/candied fruit aroma. Almost like a citrusy fruit cake kind of aroma. There's some heat from the alcohol in the taste that's mostly masked by a sticky caramel sweetness and a litle citrus hop flavor, with a lingering bitterness in the finish. I'm dying to get some of the recent 120 minute to compare. The clone seems very close to what I remember. I think the areas where Paxton's recipe was woefully short were yeast pitching rates and hopping rates.

That got me thinking about what I would change if/when I would brew this again.

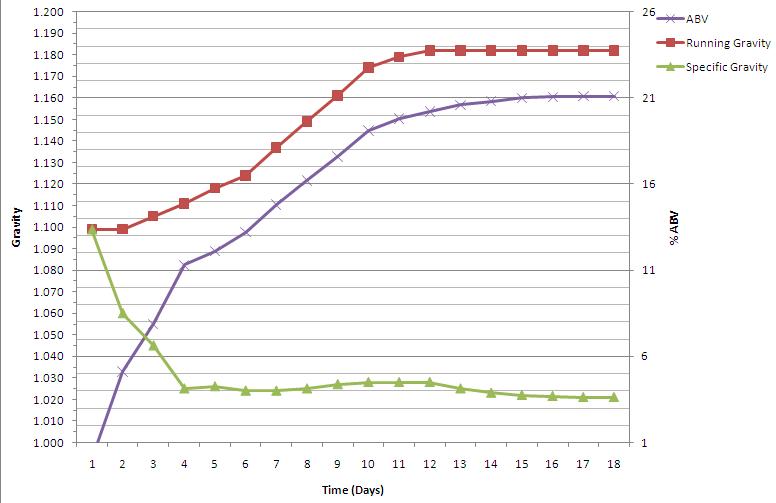

A. To all those that said this should be as dry as possible, you were 100% right. In retrospect I think this beer could have been better if I stopped adding sugar sooner. I would have loved if it finshed at like 1.010

B. Building on that idea, now that I have the bug out of my system to make a beer as strong as can be, I believe this beer would be best brewed around 1.130 instead of 1.182. Still shoot for around 1.100 from malt, and then add around 4.5lbs of dextrose. Ideally drying it out around 1.010 to 1.016. Maybe 15% ABV.

C. Way more hops. I added way more hops, but I'm talking way more hops than that.

D. I'm thinking about Hop extract. After listening to Vinnie from Russian River, and the brewer from Lagunitas talk about the benefits of using it for bittering these insanely big IPAs, I think it would be a good idea. Initially I was thinking about 6oz of Warrior for bittering between 90min and 60min(About 100AAU worth), but now I'm thinking about 100AAU worth of hop extract. Northern Brewer sells those hop shot syringes.

E. Citra. I love the Amarillo and Simcoe combo, and I've added citra, and the three are great together.

Assuming I can get my hands on a good chunk of the 2011 Amarillo, Simcoe, and Citra crop, I might brew:

Same grain bill

Hops:

6oz Warrior continuously hopped from 90 to 60min (or 100AAU of hop shot)

2oz ea Simcoe, Amarillo, and Citra hopped continuously from 30min to 0min

1.5oz ea Simcoe, Amarillo, and Citra added at flameout

Allow hops to steep hot for 10min

Same yeast, same pitching rates, same temp

Add 4.5lbs Dextrose added incrementally over 7 days 12oz per addition, twice/day

Rack to secondary after it hits FG, then dry hop with 9oz total of the same simcoe/amarillo/citra mix. Add an ounce every couple days for two weeks, then allow it to sit on the bed of hops for a month.

The goal being a mix between Pliny the Younger and 120 Minute. 15% ABV, nice and dry, and extremely hoppy. It'll be a long while before I do another brew this demanding, so don't expect any results for at least 6 months =)

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)

You may have an angle here...

You may have an angle here...