Owly055

Well-Known Member

- Joined

- Feb 28, 2014

- Messages

- 3,008

- Reaction score

- 687

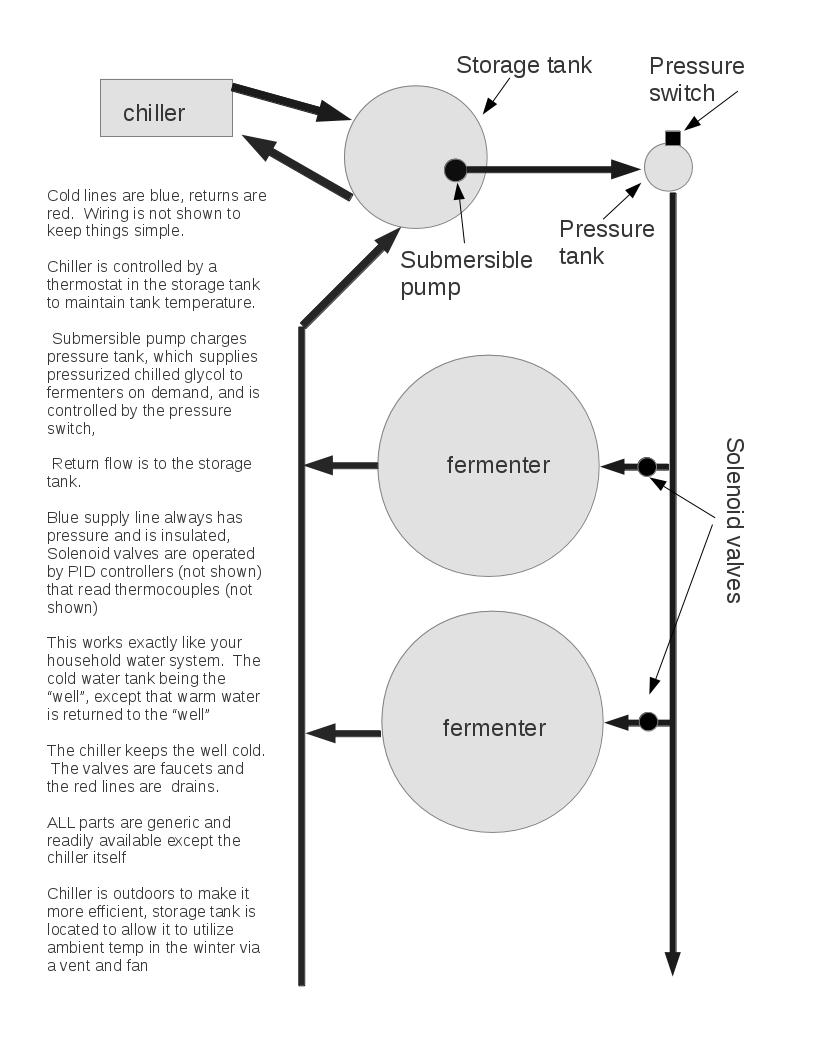

A friend of mine owns a microbrewery, and is frustrated with his chiller system. It's a compact unit with a complete refrigeration system, a condenser and evaporator / heat exchanger, a tank and a circulating pump. It's noisy and generates a lot of heat, and runs steadily controlling temps on his fermenters and chilling wort. The problem is that it has almost no storage capacity, nor does it take advantage of cold outside air. Most of the year outdoor temps here drop near or below freezing. A condenser in cold air is far more efficient than one in room temp, thus using far less energy. My proposed system uses a small insulated room outside the main brewery, set up to draw in outside air when it's cold outside, and the chiller unit is essentially outside under a roof in a shaded area. The system will contain a large storage tank (200 gallon), and an ordinary household well pressure tank. A submersible pump will sit in the 200 gallon tank, and maintain 60 pounds or so pressure in the pressure tank and lines, which will be insulated. A pressure switch.... an ordinary well type pressure switch will cycle the submersible pump, a $300 well submersible pump from Home Depot. A thermostat in the large storage tank will operate the chiller. Two main lines, a pressure line from the pressure tank, carrying cold glycol, and a return line back to the storage tank, carrying warm glycol. Each fermenter will have a PID controller and thermocouple operating a solenoid valve to feed it glycol as needed. As an afterthought, a return loop from the pressure to the return should recycle the glycol to the storage tank to keep the glycol in the pressure tank and lines cold when none is being used. This would run from a PID controller sensing line temp.

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)