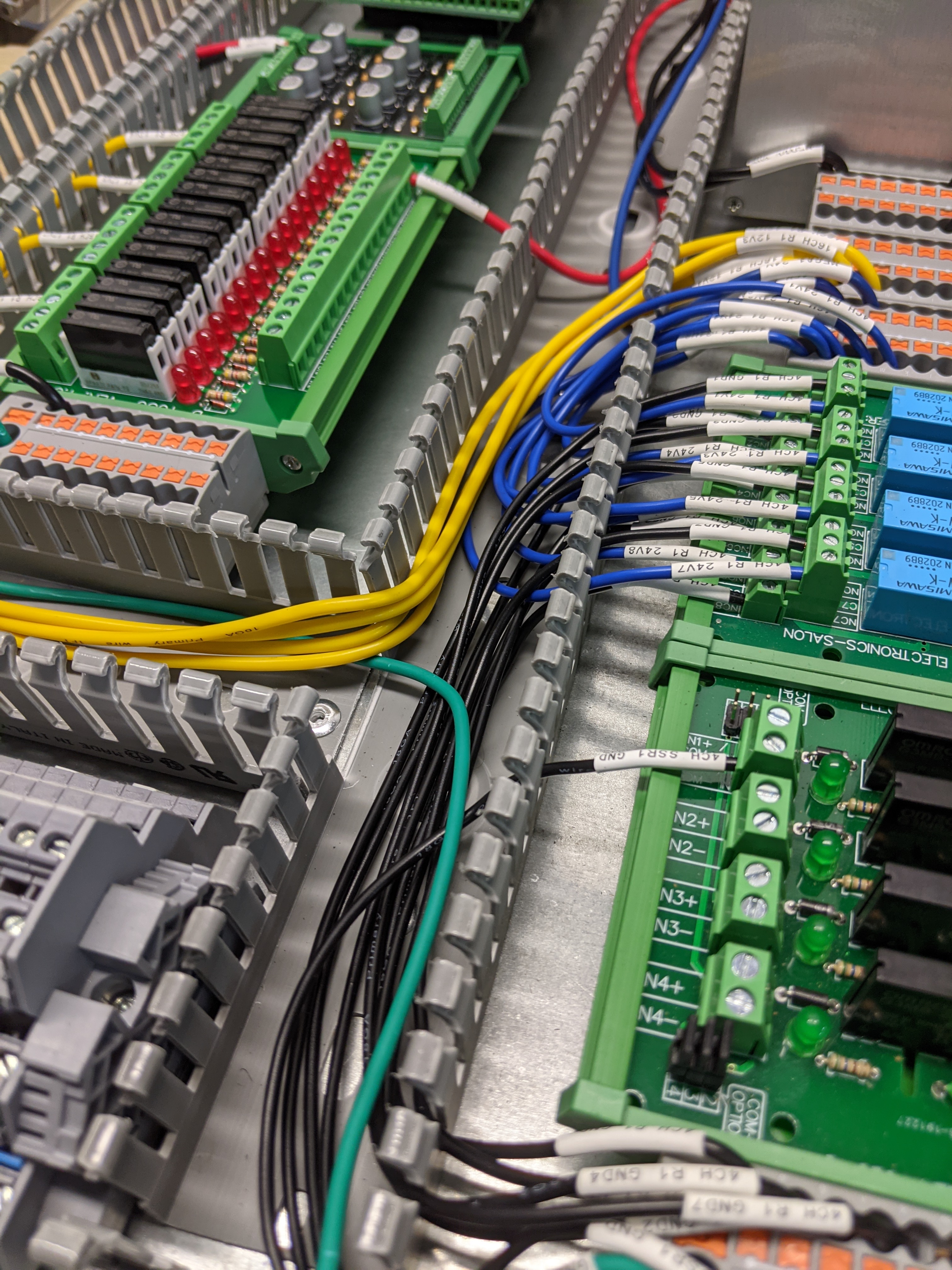

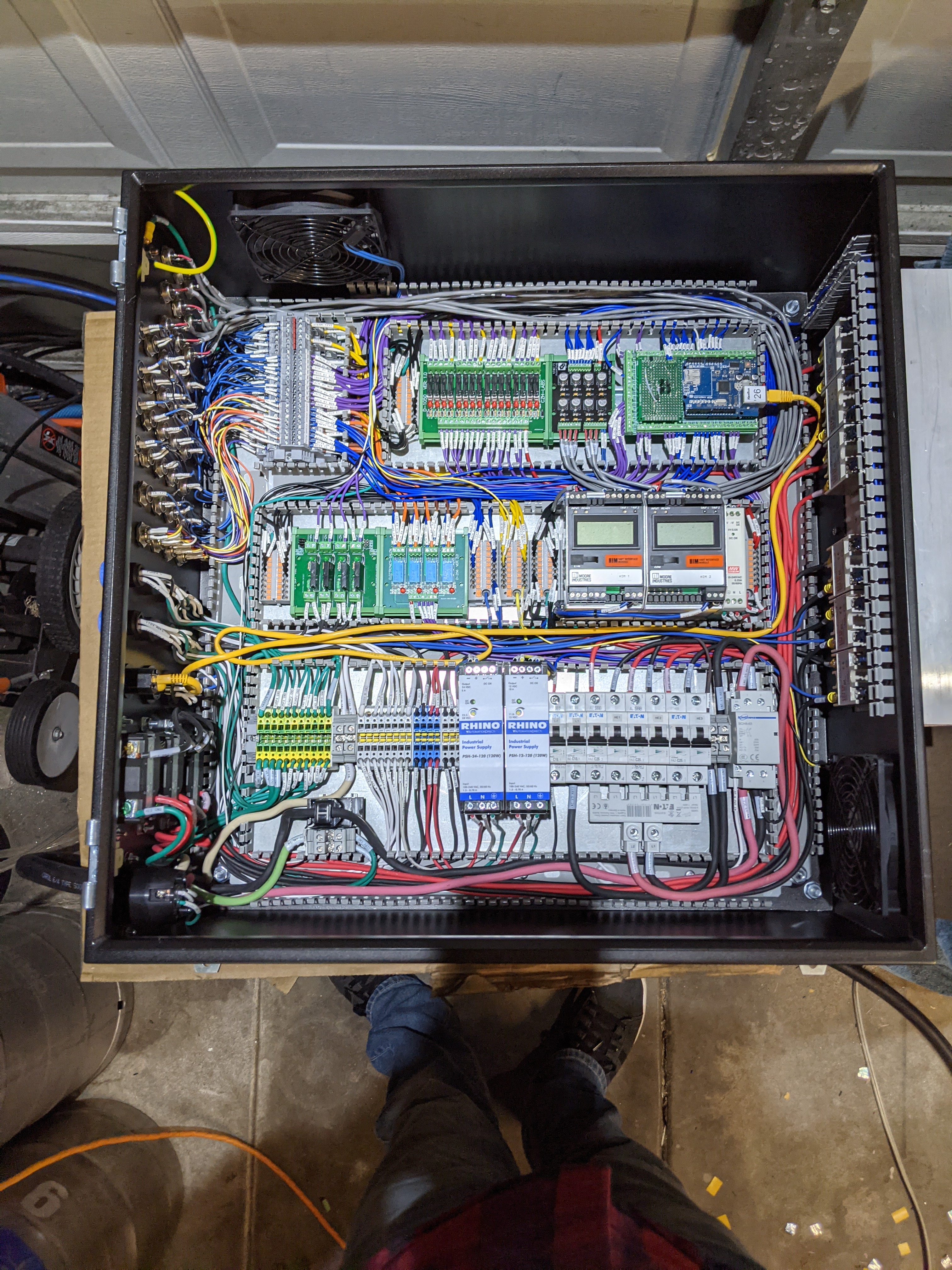

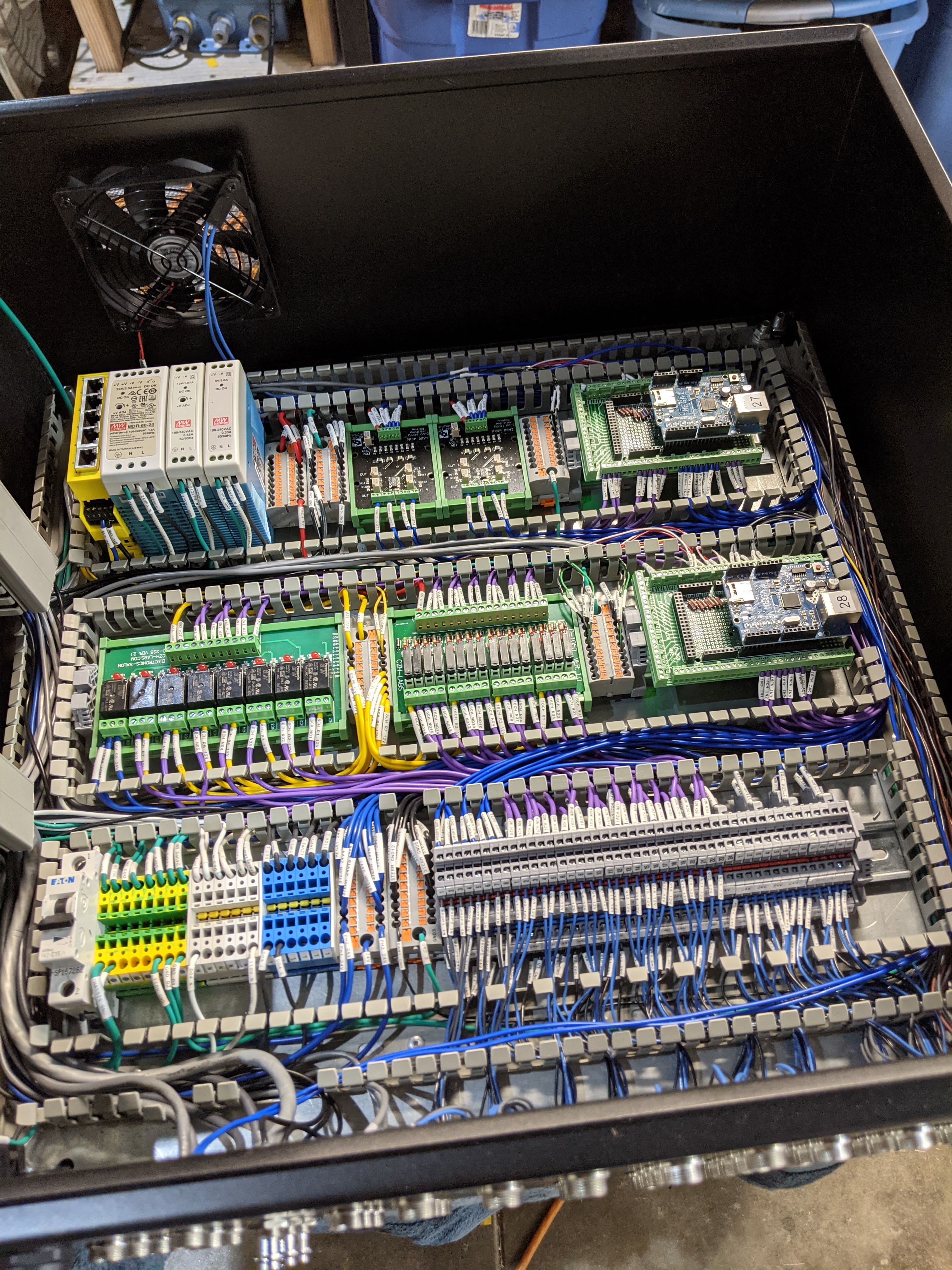

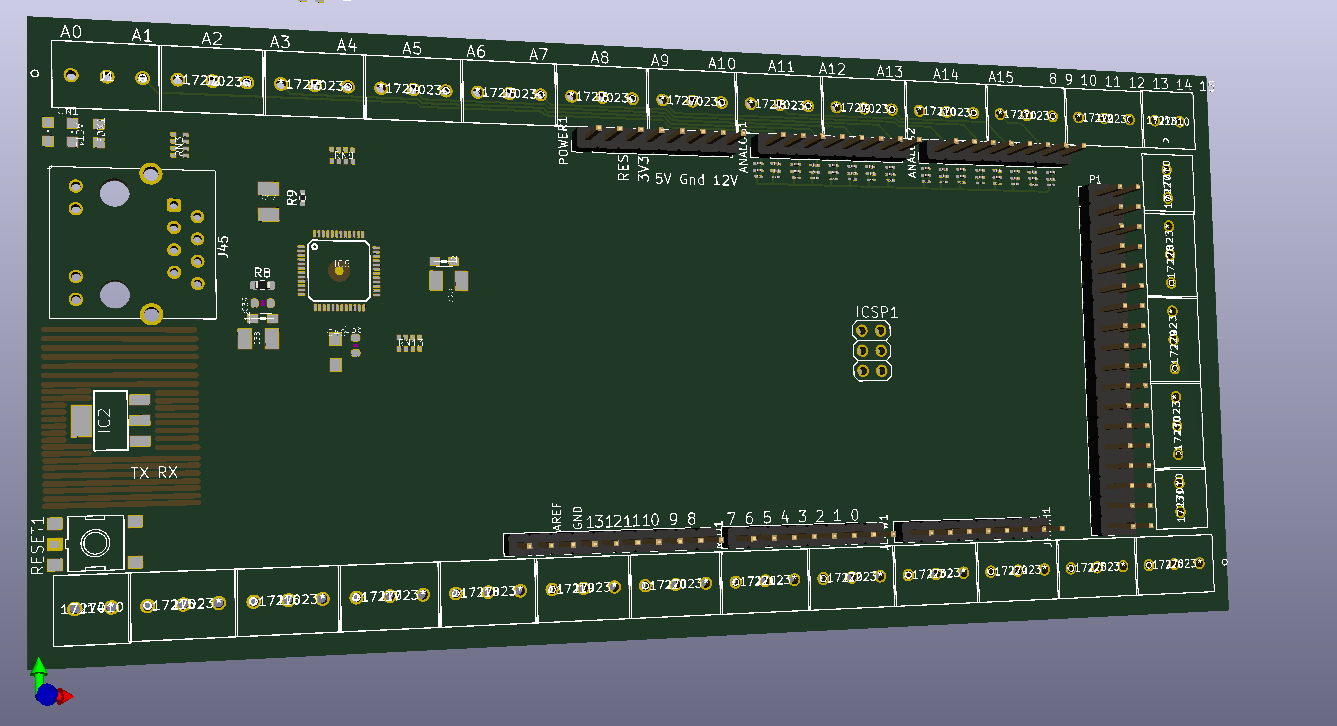

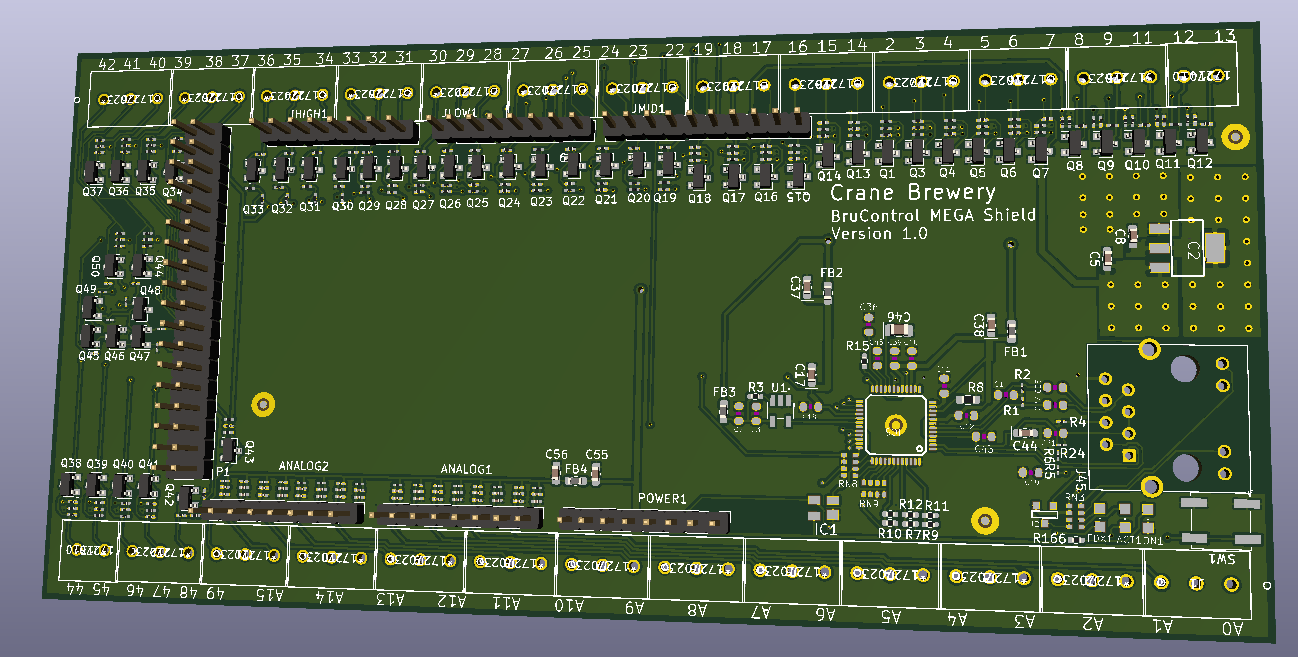

So between the 2 panels, here are all the features. I have 3 arduino megas that have all but one analog input used.

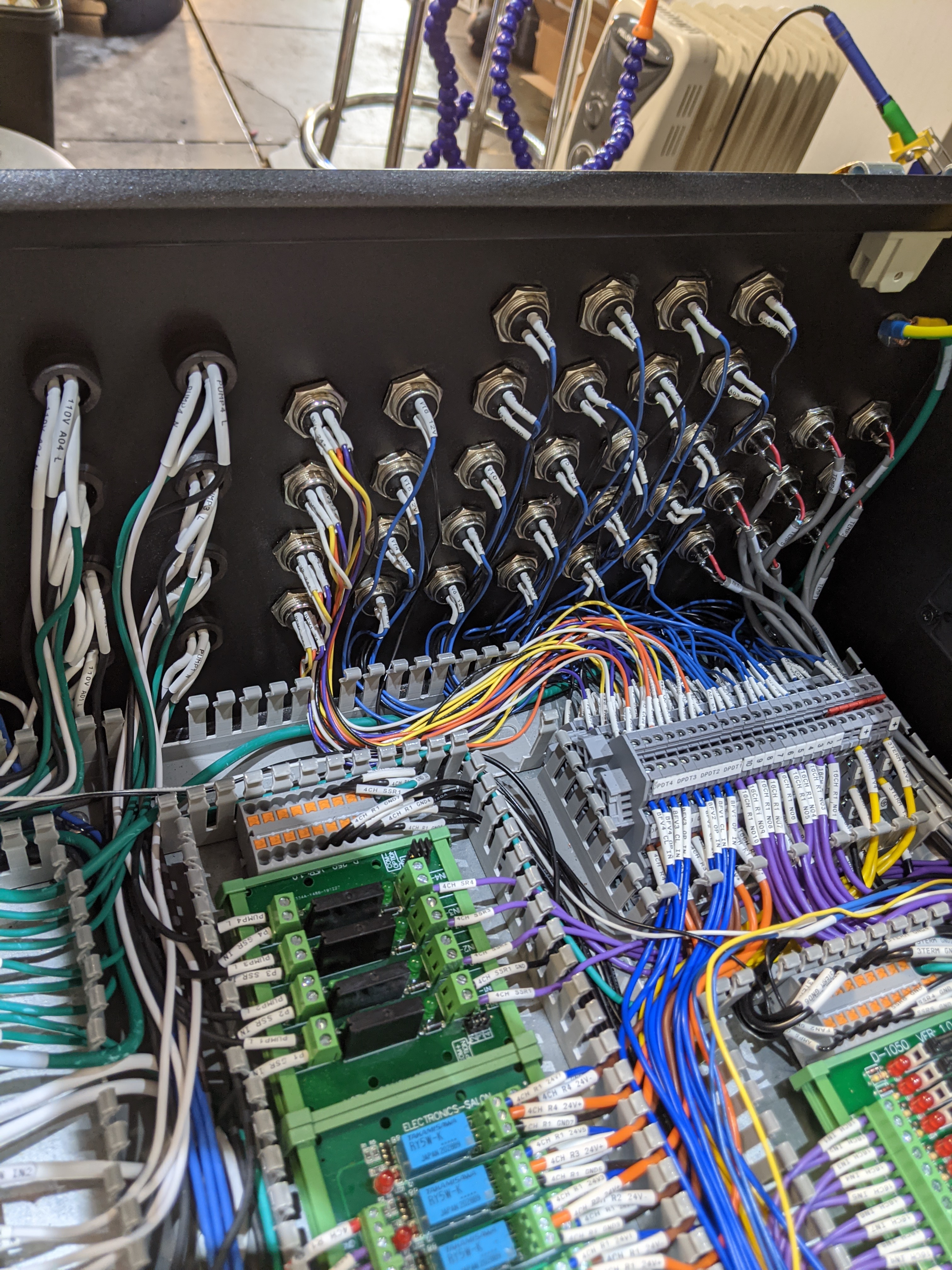

39 12V relays for ball valves and solenoid valves

8 proportional valves

4 DPDT relay board for the large electronic butterfly valves

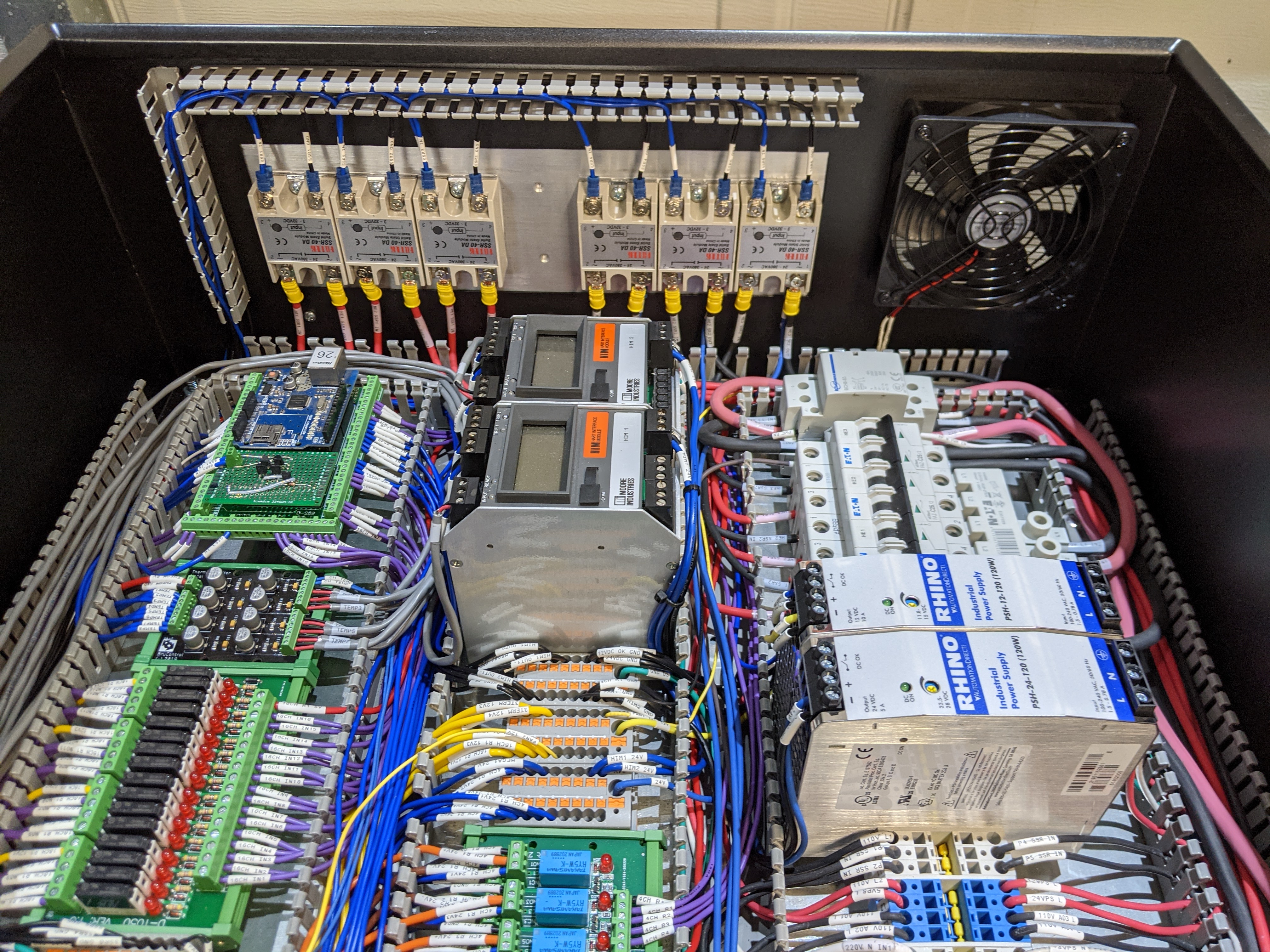

4 channel SSR board for AC pump control

4 always on 110V outlets for MFM transmitters/etc.

8 always on 12V outputs for dosing pump/hop boss/etc.

8 thermistor inputs (2 used for chassis exhaust temperature monitoring)

5 IFM SM6004 inputs (flow and temperature)

2 Micro Motion MFMs (density, flow, temp)

3 PH meters/sensor (PH and temperature)

4 DO meters/sensors (DO and temperature)

1 conductivity sensor for monitoring RO filter TDS

8 pressure sensors/0-5V inputs

Current sensor for heating elements

3 heating element outputs (2 are using my time sharing solution)

5 port network switch. 1 uplink, 3 megas, 1 spare

2 fans for each panel

panel mount USB connector for each mega for FW upgrades

Since I am using the Rugged Circuit's megas, I can/am powering them off of the 24V power supplies. This allows me to monitor the DC ok outputs from the 5V and 12V power supplies. As long as 24V is up, then the megas and ethernet switch will be powered on, and able to communicate. If there is a problem with the 5V or 12V power supplies I can have an alarm for that.