You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

CraftBeerPi - Raspberry Pi Software

- Thread starter chixxi

- Start date

Help Support Homebrew Talk:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

Austinjs0102

Active Member

Question: Is there a way to set up CraftBerrPi with 240v 5500 element? has anyone done this.

Planning a eBIAB with a Pi, 5500 watt element, pump and 10 gallon kettle. Would the 5500 be over kill? Mostly looking to have a software interface as well as more automation.

Thanks!

Planning a eBIAB with a Pi, 5500 watt element, pump and 10 gallon kettle. Would the 5500 be over kill? Mostly looking to have a software interface as well as more automation.

Thanks!

Question: Is there a way to set up CraftBerrPi with 240v 5500 element? has anyone done this.

Planning a eBIAB with a Pi, 5500 watt element, pump and 10 gallon kettle. Would the 5500 be over kill? Mostly looking to have a software interface as well as more automation.

Thanks!

Element size doesn't matter to the pi, just get the proper sized ssr relay.

Austinjs0102

Active Member

Element size doesn't matter to the pi, just get the proper sized ssr relay.

Perfect, was just looking at that as well.

Think i have this all sorted out. Im not going to build still for another few months but might as well get some of it planned now!

adding an edit:

Would anyone have a 240v Diagram for the CraftBeerPi. If not, ill work on one for a 30A eBIAB system. Might be worth doing.

SHvanBommel

Well-Known Member

- Joined

- Nov 5, 2007

- Messages

- 548

- Reaction score

- 57

I will be releasing recommended diagrams when we release the official. Board for cbpi

Austinjs0102

Active Member

I will be releasing recommended diagrams when we release the official. Board for cbpi

Thanks much!

I was looking at the diagram on the site and my only concern is i cant tell what the colors are in reference too. For mine, it would be 240V so 2 hot, 1 ground and 1 Neutral coming into the box. The sit only shows a total of 3.

Will wait for it for now!

Doing an Edit:

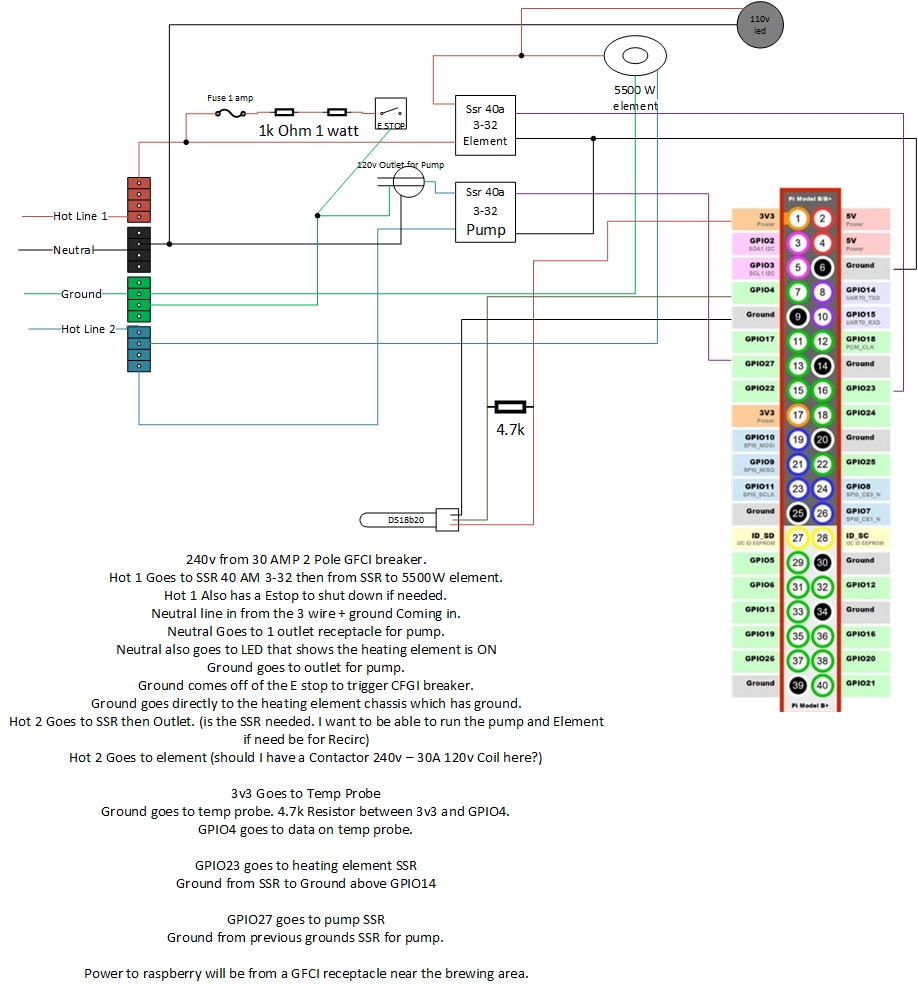

Im still reading vastly on all this and am not doing any electrical or controller work right now. Below is a diagram i made. Its quite bland but should be able to follow. Please let me know if this is viable for a 240v 1 element,1 pump,1 temp probe BeerPi setup.

Thanks

$53.24

1pc Hose Barb/MFL 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304(Gas MFL)

Guangshui Weilu You Trading Co., Ltd

$33.99 ($17.00 / Count)

$41.99 ($21.00 / Count)

2 Pack 1 Gallon Large Fermentation Jars with 3 Airlocks and 2 SCREW Lids(100% Airtight Heavy Duty Lid w Silicone) - Wide Mouth Glass Jars w Scale Mark - Pickle Jars for Sauerkraut, Sourdough Starter

Qianfenie Direct

$76.92 ($2,179.04 / Ounce)

Brewing accessories 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304 Brewing accessories(Gas Hose Barb)

chuhanhandianzishangwu

$53.24

1pc Hose Barb/MFL 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304(Liquid Hose Barb)

yunchengshiyanhuqucuichendianzishangwuyouxiangongsi

$58.16

HUIZHUGS Brewing Equipment Keg Ball Lock Faucet 30cm Reinforced Silicone Hose Secondary Fermentation Homebrew Kegging Brewing Equipment

xiangshuizhenzhanglingfengshop

$44.99

$49.95

Craft A Brew - Mead Making Kit – Reusable Make Your Own Mead Kit – Yields 1 Gallon of Mead

Craft a Brew

$7.79 ($7.79 / Count)

Craft A Brew - LalBrew Voss™ - Kveik Ale Yeast - For Craft Lagers - Ingredients for Home Brewing - Beer Making Supplies - (1 Pack)

Craft a Brew

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)

$6.95 ($17.38 / Ounce)

$7.47 ($18.68 / Ounce)

Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]

Hobby Homebrew

$719.00

$799.00

EdgeStar KC2000TWIN Full Size Dual Tap Kegerator & Draft Beer Dispenser - Black

Amazon.com

$176.97

1pc Commercial Keg Manifold 2" Tri Clamp,Ball Lock Tapping Head,Pressure Gauge/Adjustable PRV for Kegging,Fermentation Control

hanhanbaihuoxiaoshoudian

$22.00 ($623.23 / Ounce)

AMZLMPKNTW Ball Lock Sample Faucet 30cm Reinforced Silicone Hose Secondary Fermentation Homebrew Kegging joyful

无为中南商贸有限公司

$20.94

$29.99

The Brew Your Own Big Book of Clone Recipes: Featuring 300 Homebrew Recipes from Your Favorite Breweries

Amazon.com

$49.95 ($0.08 / Fl Oz)

$52.99 ($0.08 / Fl Oz)

Brewer's Best - 1073 - Home Brew Beer Ingredient Kit (5 gallon), (Blueberry Honey Ale) Golden

Amazon.com

$479.00

$559.00

EdgeStar KC1000SS Craft Brew Kegerator for 1/6 Barrel and Cornelius Kegs

Amazon.com

SHvanBommel

Well-Known Member

- Joined

- Nov 5, 2007

- Messages

- 548

- Reaction score

- 57

View attachment ImageUploadedByHome Brew1484794816.823824.jpgno big deal but... this is the second to last if not the last round of dev boards before the official boards come out. ;-) stay tuned!

toadyus

Well-Known Member

UPDATE - Full Components for the boards have been sourced and delivered. I have sent a PM to all those that were initially interested when I first sent out my initial message about getting some boards made and should have a couple extra boards. The cost for the DIY is $20 USD and an assembled / tested board is $40USD. I'll need your postal / zip code for shipping costs. If you're interested please send me a pm. Thanks.

Bigdaddyale

Well-Known Member

Can you post the BOM for this board?UPDATE - Full Components for the boards have been sourced and delivered. I have sent a PM to all those that were initially interested when I first sent out my initial message about getting some boards made and should have a couple extra boards. The cost for the DIY is $20 USD and an assembled / tested board is $40USD. I'll need your postal / zip code for shipping costs. If you're interested please send me a pm. Thanks.

toadyus

Well-Known Member

You betcha!!

Thanks much!

I was looking at the diagram on the site and my only concern is i cant tell what the colors are in reference too. For mine, it would be 240V so 2 hot, 1 ground and 1 Neutral coming into the box. The sit only shows a total of 3.

Thanks

Most of the world (including germany where the project originates) uses 240v 13a to standard domestic sockets so hence require only 3 wires (Live neutral and earth) for their circuitry.

Whistler94

Member

Hey! Anyone know if this system could handle a glycol chilling fermentation across multiple fermenters? We currently have 2 vessels each with ball valve to direct the flow of glycol. I know i could hook up the Cooling GPIO per vessel to the ball valve via relay and such, but my main concern is the glycol pump. I would need to have that turned on when ANY of the vessels are in cooling mode. Is this possible? I could also use a few diodes and have this work outside of the pI but i would love if it was already integrated.

Thanks in advance!

Thanks in advance!

SHvanBommel

Well-Known Member

- Joined

- Nov 5, 2007

- Messages

- 548

- Reaction score

- 57

The best option I've been able to reason out is to create a cooling loop just for your glycol cooler and pump to keep the glycol at a set temp and then actuate the valves as you stated earlier. It's the best way I've reasoned out so far, also: in a commercial setting (I brew professionally) the glycol reservoir and cooler have their own control and fermenters have their own control.

Whistler94

Member

The best option I've been able to reason out is to create a cooling loop just for your glycol cooler and pump to keep the glycol at a set temp and then actuate the valves as you stated earlier. It's the best way I've reasoned out so far, also: in a commercial setting (I brew professionally) the glycol reservoir and cooler have their own control and fermenters have their own control.

I agree that the cooler would have it's own control. We currently have that set up the same way now with arduino. We just don't want the glycol pump running continuesly. In your system does the pump run all the time or only when cooling is called?

spittybug

Well-Known Member

Wet run today. Not bad. My temp logging isn't working though. Suggestions? I'd love to see some more detailed documentation on the various temp control algorithms and would really appreciate a step by step on how to include the %duty algorithm code. Thanks!

Bigdaddyale

Well-Known Member

What is the 12v pad between I2C and GPIO 17 on the left hand side used for? Buzzer?

Wet run today. Not bad. My temp logging isn't working though. Suggestions? I'd love to see some more detailed documentation on the various temp control algorithms and would really appreciate a step by step on how to include the %duty algorithm code. Thanks!

If by temp logging, you mean the charts, there is a log file you need to delete. The solution is a couple pages back.

We'd all love more detailed documentation. It's getting there, but it takes time. There are instructions on implementing PWM on the pull requests on GitHub.

spittybug

Well-Known Member

Thanks for the help Ph03.. I will delete the file.

I've also been to the Github and looked at the PWM code. It looks like reasonable logic from what I can decipher. How do I actuallyget that code onto my pi? Is there a command I can issue from my end that will (like a sudo git pull) get the right file and put it in my directory? Or do I have to copy/paste something?

Sorry for the newbie question, but I'm a brewer not a computer guy and I'm learning more and more everyday!

Thanks.

I've also been to the Github and looked at the PWM code. It looks like reasonable logic from what I can decipher. How do I actuallyget that code onto my pi? Is there a command I can issue from my end that will (like a sudo git pull) get the right file and put it in my directory? Or do I have to copy/paste something?

Sorry for the newbie question, but I'm a brewer not a computer guy and I'm learning more and more everyday!

Thanks.

divi2323

Well-Known Member

Does anyone have a link to the different control logics listed for a kettle and how they are intended to be operated?

Spent tonight reading the entire thread and it doesnt mention what all of the different options and parameters are for them.

Spent tonight reading the entire thread and it doesnt mention what all of the different options and parameters are for them.

Does anyone have a link to the different control logics listed for a kettle and how they are intended to be operated?

Spent tonight reading the entire thread and it doesnt mention what all of the different options and parameters are for them.

A lot of the new control logic types were just added in 2.2. As far as I know they are not documented. PID is pretty standard. Hystersis is an overshoot that i only use for fermentation. Those and my PWM are the only ones I use, so maybe others can fill in the rest.

One option is to fill your kettle with water and test how the different control logics act. The other is to read through the code (Python is pretty easy to understand with a minimum of programming knowledge).

Thanks for the help Ph03.. I will delete the file.

I've also been to the Github and looked at the PWM code. It looks like reasonable logic from what I can decipher. How do I actuallyget that code onto my pi? Is there a command I can issue from my end that will (like a sudo git pull) get the right file and put it in my directory? Or do I have to copy/paste something?

Sorry for the newbie question, but I'm a brewer not a computer guy and I'm learning more and more everyday!

Thanks.

PWM is only in the pull request phase, so you have to edit the files manually. I posted instructions in the "conversation" tab of my pull request. If you need help beyond that, just PM me.

divi2323

Well-Known Member

A lot of the new control logic types were just added in 2.2. As far as I know they are not documented. PID is pretty standard. Hystersis is an overshoot that i only use for fermentation. Those and my PWM are the only ones I use, so maybe others can fill in the rest.

One option is to fill your kettle with water and test how the different control logics act. The other is to read through the code (Python is pretty easy to understand with a minimum of programming knowledge).

Thanks for the reply. I'm new to CBP, so didnt know the new control logics were just introduced. Today i'm doing just what you suggested to bring the system online with a water boil.

Do you find the P, I, and D settings are sufficient for all size batches, or is it geared more towards a 5 or 10 gallon batch? My system has the capability of doing a 20 gallon boil in a 25 gallon pot, so i'd hate to use a control that's more for the smaller batches if I can avoid it.

Maybe i'll post some results if I get to it tonight for each of these.

Thanks for the reply. I'm new to CBP, so didnt know the new control logics were just introduced. Today i'm doing just what you suggested to bring the system online with a water boil.

Do you find the P, I, and D settings are sufficient for all size batches, or is it geared more towards a 5 or 10 gallon batch? My system has the capability of doing a 20 gallon boil in a 25 gallon pot, so i'd hate to use a control that's more for the smaller batches if I can avoid it.

Maybe i'll post some results if I get to it tonight for each of these.

I haven't adjusted the PID settings from the defaults, but there is a post on tuning PID here: https://www.homebrewtalk.com/showthread.php?t=174020

My system can only do 10 gallons with 16 gallon keggels, so I am not sure about tuning for that level.

divi2323

Well-Known Member

Didnt get around to doing a boil today in the shop. I did get a lot done IN said shop though, so happy with that.

Right now i'm kind of battling the bug where the graph doesnt display properly. I delete the templog files in the log directory to fix it but that hardly seems like a permanent fix. Is the issue that the log file is too much to read (too many data points?) and it fills up and doesnt read or is the bug source not yet known?

Right now i'm kind of battling the bug where the graph doesnt display properly. I delete the templog files in the log directory to fix it but that hardly seems like a permanent fix. Is the issue that the log file is too much to read (too many data points?) and it fills up and doesnt read or is the bug source not yet known?

Didnt get around to doing a boil today in the shop. I did get a lot done IN said shop though, so happy with that.

Right now i'm kind of battling the bug where the graph doesnt display properly. I delete the templog files in the log directory to fix it but that hardly seems like a permanent fix. Is the issue that the log file is too much to read (too many data points?) and it fills up and doesnt read or is the bug source not yet known?

I thought that might be it at first, but I have had my fermenter running for 11 days and am able to still read the graph. I'm not sure where the bug there is.

I would contribute to this project if it had a true open source license.

I don't contribute to projects that prohibit commercial use or redistribution with changed code. That isn't open source.

What often happens with these sorts of projects is that the project "owner" takes the project back to closed source status after the community has made a lot of contributions.

I urge you to change the license on this project.

I don't contribute to projects that prohibit commercial use or redistribution with changed code. That isn't open source.

What often happens with these sorts of projects is that the project "owner" takes the project back to closed source status after the community has made a lot of contributions.

I urge you to change the license on this project.

Until everyone designs it into their system and one day it isn't free. It has happened before. All he needs to do is change the license and if he is the sole copyright owner, that can easily be done.I don't see that happening. This software was developed for homebrewers, and it's free for us!

On the commercial side I see no problem with Manuel getting a cut if people want to use his software to make money!

It won't happen because commercial users will want the power to enhance and distribute enhancements as they see fit.

And it isn't (or shouldn't be) Manuel's software if people send in enhancements and debug it.

Hi all. I've been lurking for a while here as I'm planning my Kai-inspired electric set up. I'm toying with automating as much as possible and have numerous complexities that I'd like the flexibility to implement (less for utility and more due to because-I-can factor). I've been intrigued by this project, but as I understand it is limited to no parallel processes and no implementation of other hardware inputs (e.g. water/wort volume switches). For the example, open an actuated valve and trigger the pump until a kettle hits a certain level and then go to the next step in the process. I just wanted to make sure that there are no current work arounds or near term implementations on the road map for such flexibility.

Any comments would be greatly appreciated.

Thanks in advance and happy brewing.

Any comments would be greatly appreciated.

Thanks in advance and happy brewing.

Hi all. I've been lurking for a while here as I'm planning my Kai-inspired electric set up. I'm toying with automating as much as possible and have numerous complexities that I'd like the flexibility to implement (less for utility and more due to because-I-can factor). I've been intrigued by this project, but as I understand it is limited to no parallel processes and no implementation of other hardware inputs (e.g. water/wort volume switches). For the example, open an actuated valve and trigger the pump until a kettle hits a certain level and then go to the next step in the process. I just wanted to make sure that there are no current work arounds or near term implementations on the road map for such flexibility.

Any comments would be greatly appreciated.

Thanks in advance and happy brewing.

You can control other devices through the software, but there is no automation for pumps, valves, etc. I believe that this is planned for later in the current release.

SHvanBommel

Well-Known Member

- Joined

- Nov 5, 2007

- Messages

- 548

- Reaction score

- 57

It's not limited in the way you say, you can run multiple processes, our aim is to expand this portion of the brewing module in the next few releases. This IS open source software so if you have the skills and want to take a crack at it Manuel is more then happy for the help. As to what brewman was saying re: closing the software, we have been discussing this at great length and though the heart of the code beats open source there are limitations for commercial use and we would not want a commercial entity to take advantage of the hard work Manuel and a smaller group of contributors Has made.

toadyus

Well-Known Member

Wow a post reassuring everyone that the license terms won't change from someone who only came back to HBT to offer his ripped off non-credited daughter boards "for-sale" is hilarious....

SHvanBommel

Well-Known Member

- Joined

- Nov 5, 2007

- Messages

- 548

- Reaction score

- 57

Hey man, none of the official board is ripped off and I certainly have not excluded credit where it's due. As for coming back to hbt just to sell boards is a bit harsh, I'd be curious as to what your "beef" is, send me a message and we can figure it out.

I have a question about temperature logic.... I have a Hosehead system (works awesome so far) but not sure what logic I am supposed to use for boil? Is there a way to have a rolling boiling with Craftbeerpi? I tried experimenting with the overshoot logic and whatnot but had a hard time figuring it out.

Do I just leave it on 213deg and have it always on?

What exactly is the overshoot logic by norm?

Do I just leave it on 213deg and have it always on?

What exactly is the overshoot logic by norm?

terragady

Well-Known Member

What is the 12v pad between I2C and GPIO 17 on the left hand side used for? Buzzer?

It is just output for anything you want, nothing specified. There was a space and someone 12V is needed for something else, sensors, LEDs etc. You can also use 5V from I2C for anything. It is just an open gate without any specific purpose

BTW. Nice printed board

Bigdaddyale

Well-Known Member

Thanks- Not my board but from my favorite board house. DirtyPCBs. And I can't thank you enough for the effort you put in designing this board.Thanks DudeIt is just output for anything you want, nothing specified. There was a space and someone 12V is needed for something else, sensors, LEDs etc. You can also use 5V from I2C for anything. It is just an open gate without any specific purposeIt is no harm to have it there

BTW. Nice printed board

Similar threads

- Replies

- 7

- Views

- 2K

- Replies

- 6

- Views

- 2K

- Replies

- 15

- Views

- 2K

- Replies

- 9

- Views

- 4K