thestealth

Active Member

- Joined

- Aug 29, 2015

- Messages

- 39

- Reaction score

- 14

Yeah but if you make it that neat, no troubleshooting will be needed. Where's the fun in that??

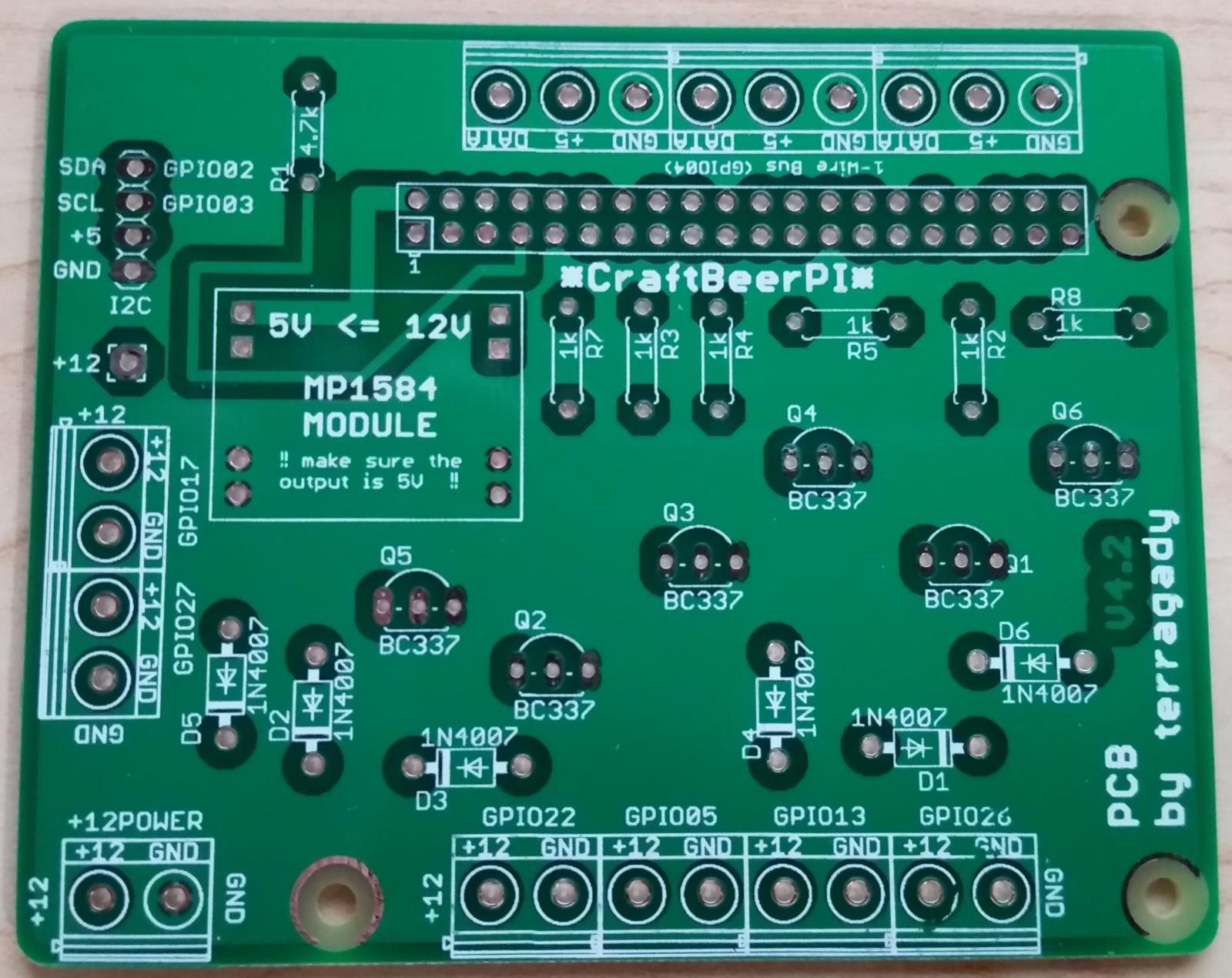

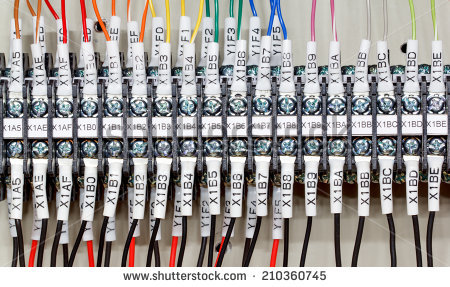

I could have been really neat and do something as pictured below, but that has 2 problems:

1- It costs a lot more

2- No fun tracing wires

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)