I need to do a bit of reading, but for 40-50 bucks assembled, I'm probably quite interested!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

CraftBeerPi - Raspberry Pi Software

- Thread starter chixxi

- Start date

Help Support Homebrew Talk:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

SHvanBommel

Well-Known Member

- Joined

- Nov 5, 2007

- Messages

- 548

- Reaction score

- 57

It takes me 1 month from order date to my mailbox to get boards from Dirty Cheap PCBs.I'm in California.

Agree

There was a recent post on the CBP Facebook page about support for wifi controlled sockets. Has anyone set one up?

I am interested in setting up wireless sockets for fermentation temp control using the fermentation dashboard of v2.2.

Will I need to dive into the python to get one configured? I don't recall seeing references to wifi connectors in the setup.

Thanks

I am interested in setting up wireless sockets for fermentation temp control using the fermentation dashboard of v2.2.

Will I need to dive into the python to get one configured? I don't recall seeing references to wifi connectors in the setup.

Thanks

spittybug

Well-Known Member

I just loaded this up on pi yesterday and have it running. Considering I'm an absolute neophyte with this pi/programming stuff, I'm happy with my progress so far....

A few questions though since the documentation isn't completed yet.

A few questions though since the documentation isn't completed yet.

- What does the car icon mean/do under each vessel?

- Is this strictly linear? In other words, can I be concurrently warming up my HLT from strike to mash out temperature while also going through mashing steps by turning on the HERMS pump as needed to raise the temps? (each function uses a different thermometer).

- How does one wire up 3 thermometers, one for each tank, if there is only one input GPIO for such? Are these the same kind of one-wire thermometers that I'm currently using for the Auberin PID controller?

- For testing purposes, I have it configured for dummy thermometers but they don't do anything. They are not selectable in the hardware drop downs per vessel. Should they be?

- What is the purpose of a target temperature per vessel? How is this different than the step by step target temperature?

spittybug

Well-Known Member

OK, more playing...

I am now working on the programmable step functions to answer my other questions (now that I have dummy thermometers working). I still would like answers on the real thermometer hardware however....thanks!

UPDATE.... more playing. The only apparent way to have concurrent events is by using the target temp per vessel along with the step by step process flow. So, this means (I think) setting the HLT to say 160*F to start by setting it as its target temperature and then using the step by step to turn the HERMS pump on/off to get the mash tun to the desired temperature at each mashing step. Then, sometime during the final step, manually increase the HLT temp target to mashout temps. I wouldn't want the HLT ALWAYS at mashout temps since any wort circulating through it would be heated too high and denatured. I suppose one could insert the HLT temp ramp up as the second to last step, but not knowing how long it would take makes the timeline for the alpha rest hard to calculate....... This thing would be AWESOME if it could have branched or parallel step logic flows. I think it would also be good to have the ability to have the final step be to turn off a kettle so as to potentially avoid a dry fire of an element.

All in all a good little piece of work. Thanks.

- The car icon is to turn on a particular vessel.

- The dummy thermometers must be chosen at setup, not afterwards.

I am now working on the programmable step functions to answer my other questions (now that I have dummy thermometers working). I still would like answers on the real thermometer hardware however....thanks!

UPDATE.... more playing. The only apparent way to have concurrent events is by using the target temp per vessel along with the step by step process flow. So, this means (I think) setting the HLT to say 160*F to start by setting it as its target temperature and then using the step by step to turn the HERMS pump on/off to get the mash tun to the desired temperature at each mashing step. Then, sometime during the final step, manually increase the HLT temp target to mashout temps. I wouldn't want the HLT ALWAYS at mashout temps since any wort circulating through it would be heated too high and denatured. I suppose one could insert the HLT temp ramp up as the second to last step, but not knowing how long it would take makes the timeline for the alpha rest hard to calculate....... This thing would be AWESOME if it could have branched or parallel step logic flows. I think it would also be good to have the ability to have the final step be to turn off a kettle so as to potentially avoid a dry fire of an element.

All in all a good little piece of work. Thanks.

SHvanBommel

Well-Known Member

- Joined

- Nov 5, 2007

- Messages

- 548

- Reaction score

- 57

@spittybug you need ds18b20 probes which are not at all like your "auberins" probes. Yes they are one wire so you basically wire all the data leads to gpio4, your vcc to 5vdc and ground to.. ground. Don't forget to put a 4.7k resistor between data and vcc, google has plenty of images to show you how to properly wire these probes.

$479.00

$559.00

EdgeStar KC1000SS Craft Brew Kegerator for 1/6 Barrel and Cornelius Kegs

Amazon.com

$176.97

1pc Commercial Keg Manifold 2" Tri Clamp,Ball Lock Tapping Head,Pressure Gauge/Adjustable PRV for Kegging,Fermentation Control

hanhanbaihuoxiaoshoudian

$22.00 ($623.23 / Ounce)

AMZLMPKNTW Ball Lock Sample Faucet 30cm Reinforced Silicone Hose Secondary Fermentation Homebrew Kegging joyful

无为中南商贸有限公司

$44.99

$49.95

Craft A Brew - Mead Making Kit – Reusable Make Your Own Mead Kit – Yields 1 Gallon of Mead

Craft a Brew

$53.24

1pc Hose Barb/MFL 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304(Gas MFL)

Guangshui Weilu You Trading Co., Ltd

$53.24

1pc Hose Barb/MFL 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304(Liquid Hose Barb)

yunchengshiyanhuqucuichendianzishangwuyouxiangongsi

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)

$6.95 ($17.38 / Ounce)

$7.47 ($18.68 / Ounce)

Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]

Hobby Homebrew

$49.95 ($0.08 / Fl Oz)

$52.99 ($0.08 / Fl Oz)

Brewer's Best - 1073 - Home Brew Beer Ingredient Kit (5 gallon), (Blueberry Honey Ale) Golden

Amazon.com

$33.99 ($17.00 / Count)

$41.99 ($21.00 / Count)

2 Pack 1 Gallon Large Fermentation Jars with 3 Airlocks and 2 SCREW Lids(100% Airtight Heavy Duty Lid w Silicone) - Wide Mouth Glass Jars w Scale Mark - Pickle Jars for Sauerkraut, Sourdough Starter

Qianfenie Direct

$76.92 ($2,179.04 / Ounce)

Brewing accessories 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304 Brewing accessories(Gas Hose Barb)

chuhanhandianzishangwu

$7.79 ($7.79 / Count)

Craft A Brew - LalBrew Voss™ - Kveik Ale Yeast - For Craft Lagers - Ingredients for Home Brewing - Beer Making Supplies - (1 Pack)

Craft a Brew

$719.00

$799.00

EdgeStar KC2000TWIN Full Size Dual Tap Kegerator & Draft Beer Dispenser - Black

Amazon.com

$58.16

HUIZHUGS Brewing Equipment Keg Ball Lock Faucet 30cm Reinforced Silicone Hose Secondary Fermentation Homebrew Kegging Brewing Equipment

xiangshuizhenzhanglingfengshop

$20.94

$29.99

The Brew Your Own Big Book of Clone Recipes: Featuring 300 Homebrew Recipes from Your Favorite Breweries

Amazon.com

spittybug

Well-Known Member

@spittybug you need ds18b20 probes which are not at all like your "auberins" probes. Yes they are one wire so you basically wire all the data leads to gpio4, your vcc to 5vdc and ground to.. ground. Don't forget to put a 4.7k resistor between data and vcc, google has plenty of images to show you how to properly wire these probes.

Thanks for that. I can't get my head around just how RPi knows which temp probe is which when they are all connected to the same input however....

SHvanBommel

Well-Known Member

- Joined

- Nov 5, 2007

- Messages

- 548

- Reaction score

- 57

They have unique ID's so when they are all plugged in the pi collects those ids and you have to figure out which goes to which (easy) then you assign that probe to whatever your need. View attachment ImageUploadedByHome Brew1482942605.536794.jpgthis is my configuration prior to hooking up probes. When it's all done I just go through and select which probes are for what.

spittybug

Well-Known Member

Ah, there are some smarts within the probes to identify them uniquely to the controller..... I get it.

That's a lot of hardware you have hooked up there! I'm looking at building myself a mash rake (high torque, low RPM motor) to mount on top of my tun. That, combined with my HERMS coil and recirculating pump should make mashing much more fun. I probably should work on a MLT stirrer too..... too many projects! At least it looks like automating them all is pretty straightforward now. Thanks.

That's a lot of hardware you have hooked up there! I'm looking at building myself a mash rake (high torque, low RPM motor) to mount on top of my tun. That, combined with my HERMS coil and recirculating pump should make mashing much more fun. I probably should work on a MLT stirrer too..... too many projects! At least it looks like automating them all is pretty straightforward now. Thanks.

Bigdaddyale

Well-Known Member

toadyus

Well-Known Member

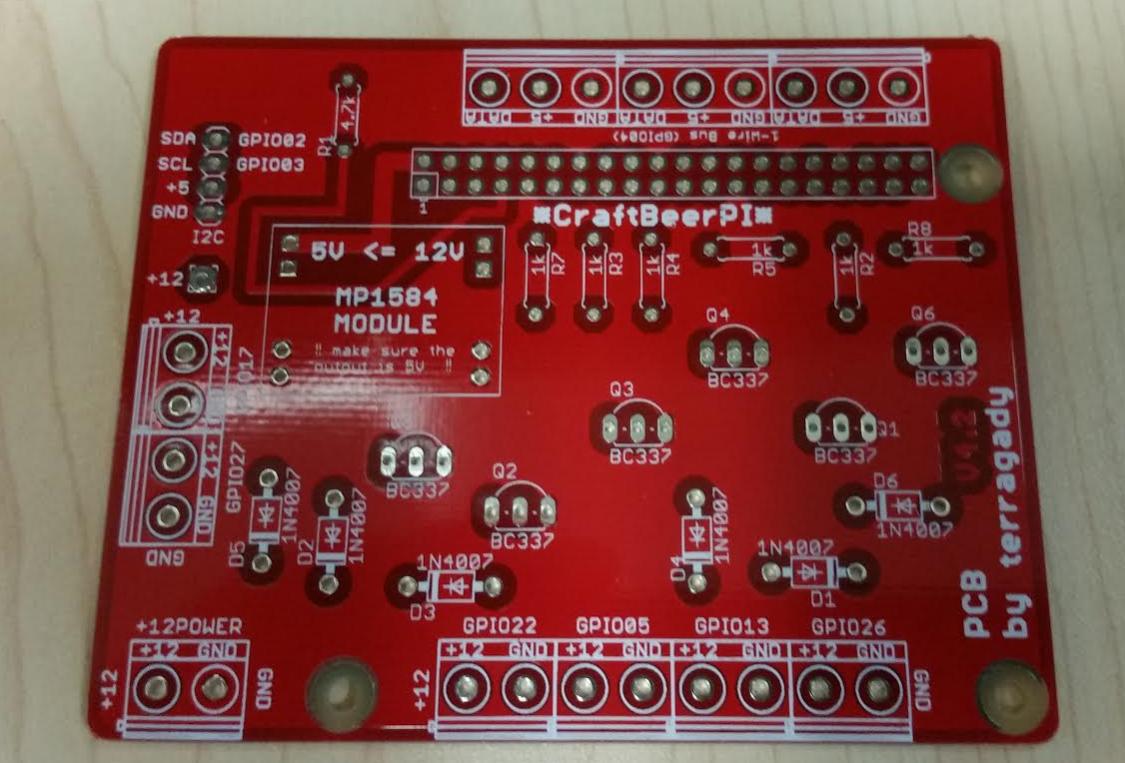

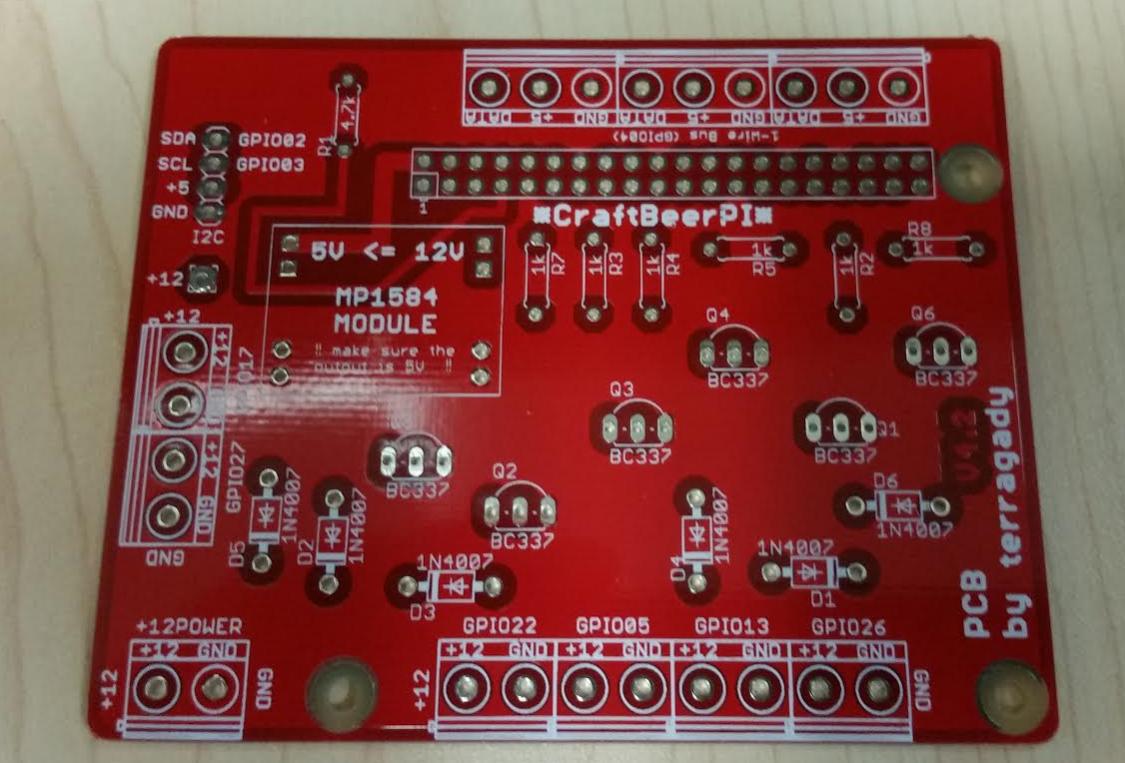

Boards have arrived and they look beautiful, just waiting on components now.

I'll definitely be interested in a put together board...soldering is not my forte! Happy New Year!

Boards have arrived and they look beautiful, just waiting on components now.

Interested in a board if you have any extra. PM sent.

Bigdaddyale

Well-Known Member

If there is still an interest in boards after SHvanBommel and toadyus sell out I can do a run of the terragady 4.2 boards pictured above.

SHvanBommel

Well-Known Member

- Joined

- Nov 5, 2007

- Messages

- 548

- Reaction score

- 57

I will be sending some PM's and then will probably do one more run of my boards and will hit up the people who are left. Cheers!

spittybug

Well-Known Member

Am I missing something or is it a no brainer for one of the choices to be % duty cycle instead of setting a target temp?

Abyssal

Active Member

- Joined

- Jul 13, 2016

- Messages

- 43

- Reaction score

- 4

Hey guys, I have a couple more questions!

I just finished wiring my setup for single vessle eBiaB with 1 pump. I'm not getting voltage through my SSR to the kettle. I'm getting it through the contactor (I'm reading 120 on one of the prongs of the receptacle, but nothing from the prong from the SSR).

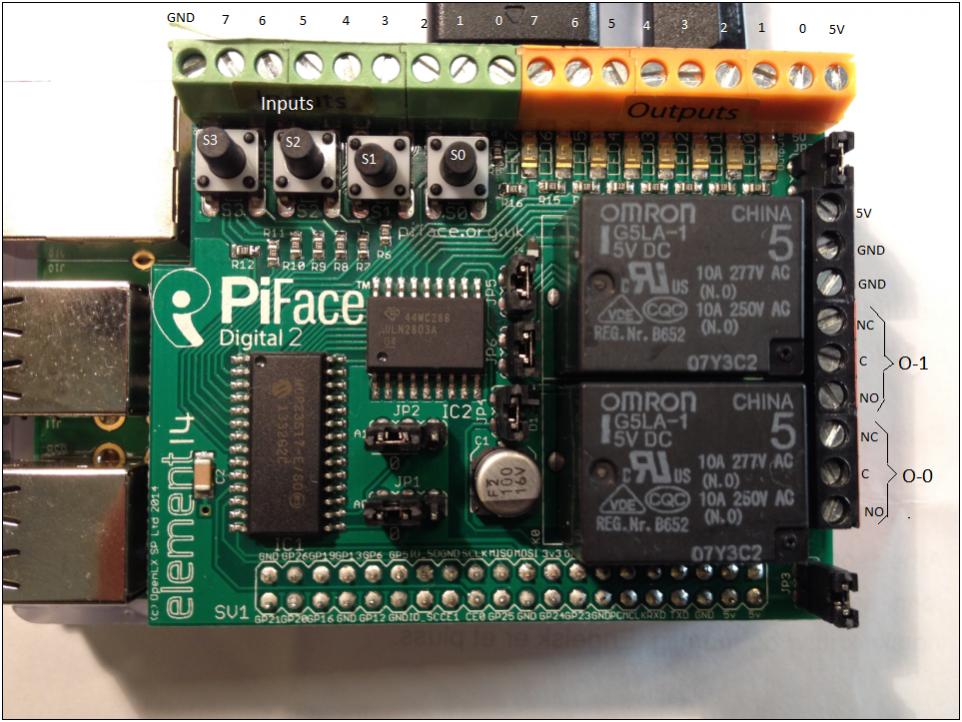

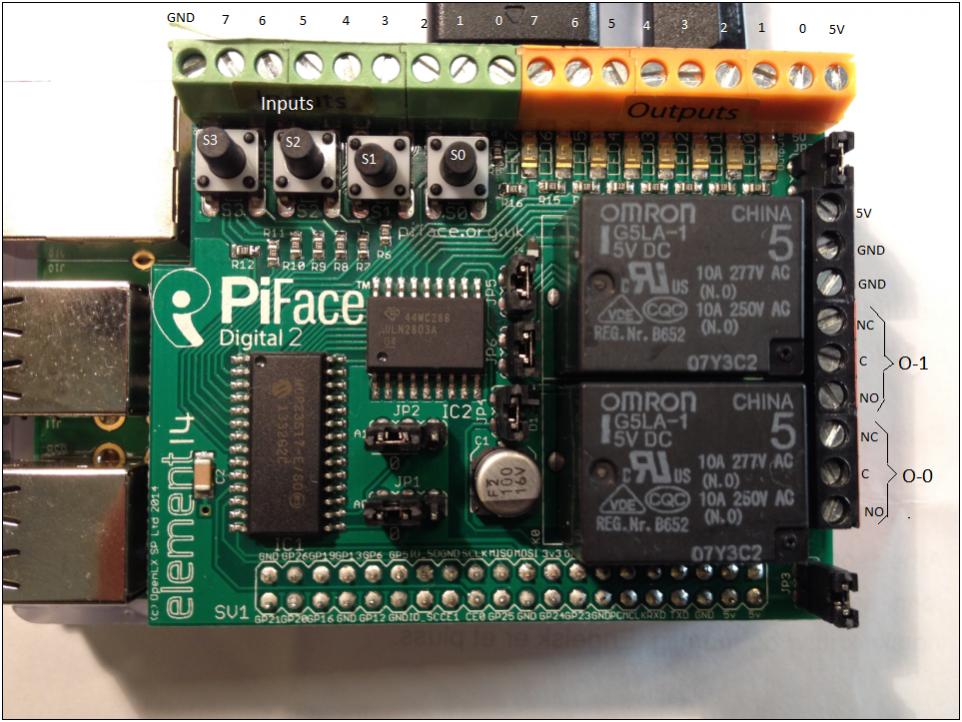

As I'm using a PiFace 2, I wanted to make sure my setup in CBP and/or my wiring is correct. I wired Outputs (orange terminals) 5V to the + side of the SSR and "0" to the - side of the SSR. When running initial setup in CBP I chose PiFace interface, then added a heater to with option of "PiFace 0".

2nd question: https://www.homebrewtalk.com/showpost.php?p=7775006&postcount=399 I followed Alt's wiring suggestion to wiring my pump receptacle to the relays on the PiFace, but I'm also getting no voltage to those. When I try to create a pump under hardware the drop down selector only has PiFace 0-7, so does that mean I won't be able to use the relay and will need another SSR to control the pump?

I just finished wiring my setup for single vessle eBiaB with 1 pump. I'm not getting voltage through my SSR to the kettle. I'm getting it through the contactor (I'm reading 120 on one of the prongs of the receptacle, but nothing from the prong from the SSR).

As I'm using a PiFace 2, I wanted to make sure my setup in CBP and/or my wiring is correct. I wired Outputs (orange terminals) 5V to the + side of the SSR and "0" to the - side of the SSR. When running initial setup in CBP I chose PiFace interface, then added a heater to with option of "PiFace 0".

2nd question: https://www.homebrewtalk.com/showpost.php?p=7775006&postcount=399 I followed Alt's wiring suggestion to wiring my pump receptacle to the relays on the PiFace, but I'm also getting no voltage to those. When I try to create a pump under hardware the drop down selector only has PiFace 0-7, so does that mean I won't be able to use the relay and will need another SSR to control the pump?

Bigdaddyale

Well-Known Member

FuzzeWuzze

I Love DIY

So decided to swap my Strangebrew box over to CraftBeerPi, i like it so far. Any advice on PID calibration, or what type of Heater setup i should use i saw you support quite a few types.

They are 20G BK and HLT HERMS setup, although i usually only do 5-10 gallon batches.

Do the automated steps not work right now? I set one up using my BK, set to 150 for 1 minute. Hit start and my BK turns green in the UI but it never actually turns on.

It would be nice if it was easier switch hysteresis settings without having to modify my kettle settings.

I mean its fairly common i believe to set your BK to 100% Duty cycle until boil, then you lower it to say 75% duty cycle on a 3-4 second period.

They are 20G BK and HLT HERMS setup, although i usually only do 5-10 gallon batches.

Do the automated steps not work right now? I set one up using my BK, set to 150 for 1 minute. Hit start and my BK turns green in the UI but it never actually turns on.

It would be nice if it was easier switch hysteresis settings without having to modify my kettle settings.

I mean its fairly common i believe to set your BK to 100% Duty cycle until boil, then you lower it to say 75% duty cycle on a 3-4 second period.

FuzzeWuzze

I Love DIY

Hey guys, I have a couple more questions!

I just finished wiring my setup for single vessle eBiaB with 1 pump. I'm not getting voltage through my SSR to the kettle. I'm getting it through the contactor (I'm reading 120 on one of the prongs of the receptacle, but nothing from the prong from the SSR).

As I'm using a PiFace 2, I wanted to make sure my setup in CBP and/or my wiring is correct. I wired Outputs (orange terminals) 5V to the + side of the SSR and "0" to the - side of the SSR. When running initial setup in CBP I chose PiFace interface, then added a heater to with option of "PiFace 0".

Im not familiar with PiFace, but it looks like there are LED's for each of the outputs? If you show your heater in the UI and click it, does the LED turn on? Does your SSR have a LED on it(mine do)?

@Abyssal

Which version CBP are you running? There's an issue posted on Github with reports of PIFace no longer working after upgrade to CBP 2.2.

Which version CBP are you running? There's an issue posted on Github with reports of PIFace no longer working after upgrade to CBP 2.2.

SHvanBommel

Well-Known Member

- Joined

- Nov 5, 2007

- Messages

- 548

- Reaction score

- 57

Doing another run of my boards, 24v/12v in. 8 outputs, buzzer, header for unused gpio. Smaller, sexier, mobetta. 35.00 built and tested, 20.00 kit only, 6 board only. Boards are 2.2 compatible.

I'm in for a board built and tested!

SHvanBommel

Well-Known Member

- Joined

- Nov 5, 2007

- Messages

- 548

- Reaction score

- 57

I should mention that this new list does not supersede the old list. There are still people out there waiting on a board that are pretty far up the line.

- Joined

- Dec 1, 2016

- Messages

- 4

- Reaction score

- 0

Hello all,

Been following this closely. Currently in the process of putting together all the pieces to build my controller.

I will be using Terragady's 4.2 board for controlling everything. My question is with this board, what is the best method for turning the pumps off and on. The heaters use an SSR but that seems overkill for a pump.

That is the last piece of the puzzle for me.

Thanks in advanced.

Bill

Been following this closely. Currently in the process of putting together all the pieces to build my controller.

I will be using Terragady's 4.2 board for controlling everything. My question is with this board, what is the best method for turning the pumps off and on. The heaters use an SSR but that seems overkill for a pump.

That is the last piece of the puzzle for me.

Thanks in advanced.

Bill

SHvanBommel

Well-Known Member

- Joined

- Nov 5, 2007

- Messages

- 548

- Reaction score

- 57

You'll have to use an SSR or breakout pins from the gpio to control a relay board such as the sainsmart 2 relay board. Fwiw, my next board has the breakout for such an instance for driving a 4 channel relay board (2 pumps, mash motor, spare or whatever your configuration)

- Joined

- Dec 1, 2016

- Messages

- 4

- Reaction score

- 0

Thanks SHvanBommel kind of figured just wanted to ensure. I am very interested in your next board with the breakouts.

Thanks again.

Thanks again.

I'm planning to use these UL listed relays inside my controller box for switching the line power to my pumps.

http://www.newark.com/webapp/wcs/stores/servlet/ProductDisplay?catalogId=15003&langId=-1&urlRequestType=Base&partNumber=92F3729&storeId=10194#productGroups

I bought the 12v panel mount version for use with SHvB's board; however, you could use the 5v through-pin version if you build your own main or breakout board. Just be aware that the 5v coil draws ~200mA and its minimum operating voltage is 3.75v, so you can't drive it directly from GPIO pins.

http://www.newark.com/webapp/wcs/stores/servlet/ProductDisplay?catalogId=15003&langId=-1&urlRequestType=Base&partNumber=92F3729&storeId=10194#productGroups

I bought the 12v panel mount version for use with SHvB's board; however, you could use the 5v through-pin version if you build your own main or breakout board. Just be aware that the 5v coil draws ~200mA and its minimum operating voltage is 3.75v, so you can't drive it directly from GPIO pins.

I finally did my first run on my CPB rig last night. I hit one little snag that i don't know a way around. I am using 220V 5500W heaters (like this: http://www.ebrewsupply.com/304-stainless-steel-element-4500w-ulwd-ripple/) to heat the water for the HERMS system and for directly heating the wort for the boil.

The problem is that since the relays for the heaters can only be fully on or fully off, I seem to have the choice between a really hard boil or no boil at all (element on of off). I got the boil temp tuned in so that the element was staying on without boiling over, but I was getting a really hard boil and boiling off a lot more liquid than I wanted.

How is anyone else handling this? My co-brewer and I were thinking we would need come kind of rheostat so that we could turn down the heating element so it was not on full power. But, we weren't having much luck finding one that we were sure would be suitable for this application.

Any advice would be greatly appreciated. Thanks!

Edit: after some more research, it looks like I should use a PWM rather than a rheostat. Does anyone have any suggestions? Is anyone else doing this?

Edit 2: This is the hightest rated one I can find. It has the voltage rating and a more than high enough amp rating, but not the wattage rating: http://www.dhgate.com/product/3800w...ZPTMxMtW0JBG9TeR3n3WXBdJF1NGgQD8CrBoCMOPw_wcB

The problem is that since the relays for the heaters can only be fully on or fully off, I seem to have the choice between a really hard boil or no boil at all (element on of off). I got the boil temp tuned in so that the element was staying on without boiling over, but I was getting a really hard boil and boiling off a lot more liquid than I wanted.

How is anyone else handling this? My co-brewer and I were thinking we would need come kind of rheostat so that we could turn down the heating element so it was not on full power. But, we weren't having much luck finding one that we were sure would be suitable for this application.

Any advice would be greatly appreciated. Thanks!

Edit: after some more research, it looks like I should use a PWM rather than a rheostat. Does anyone have any suggestions? Is anyone else doing this?

Edit 2: This is the hightest rated one I can find. It has the voltage rating and a more than high enough amp rating, but not the wattage rating: http://www.dhgate.com/product/3800w...ZPTMxMtW0JBG9TeR3n3WXBdJF1NGgQD8CrBoCMOPw_wcB

Last edited:

SHvanBommel

Well-Known Member

- Joined

- Nov 5, 2007

- Messages

- 548

- Reaction score

- 57

Yeah, pwm/duty cycle is one of the items on the list. You basically have to play with it for now or if you wanted to go analog you could look into an ssvr which works essentially as you describe your need

I finally did my first run on my CPB rig last night. I hit one little snag that i don't know a way around. I am using 220V 1500W heaters (like this: https://www.brewhardware.com/product_p/elementkit_tcrip_weld.htm) to heat the water for the HERMS system and for directly heating the wort for the boil.

The problem is that since the relays for the heaters can only be fully on or fully off, I seem to have the choice between a really hard boil or no boil at all (element on of off). I got the boil temp tuned in so that the element was staying on without boiling over, but I was getting a really hard boil and boiling off a lot more liquid than I wanted.

How is anyone else handling this? My co-brewer and I were thinking we would need come kind of rheostat so that we could turn down the heating element so it was not on full power. But, we weren't having much luck finding one that we were sure would be suitable for this application.

Any advice would be greatly appreciated. Thanks!

You don't need a rheostat. The technique most commonly used is PWM (pulse-width modulation). It involves turning the element on and off in varying proportions, usually with a period of a few seconds. So, a 10% power requirement might translate to 5 seconds on and 45 seconds off every 50 seconds. 50% power might be 25 seconds on and 25 seconds off every 50 seconds (or 10 seconds on, 10 seconds off every 20 seconds), and 80% might be 40 seconds on and 10 seconds off every 50 seconds (or 8 seconds on and 2 seconds off every 10 seconds). Clearly 0% is totally off, and 100% is totally on for any given time period.

As you can see, the percentage of power transferred to the heater is the proportion of on time to off time. The software will calculate this and turn the heater off and on accordingly.

Usually an SSR is needed for PWM, because if you use a relay it would click on and off a lot, for very short times, and would wear out quickly.

SHvanBommel

Well-Known Member

- Joined

- Nov 5, 2007

- Messages

- 548

- Reaction score

- 57

Right but there is no pwm built into cbpi yet. As a behavior for output to a heater I mean.

Right but there is no pwm built into cbpi yet. As a behavior for output to a heater I mean.

Ah, yes. I was trying to explain what PWM is, and why a rheostat is not necessary, and why an SSR is.

I think BrewPi Spark does PWM for heater loads.

I found this post where the guy is using an SCR. Would this be an option?

[ame]https://www.youtube.com/watch?v=A-jDnFt402A[/ame]

One like this maybe?

http://www.ebay.com/itm/110v-220V-1...6c359&pid=100338&rk=11&rkt=30&sd=251251998263

I'm having a tough time finding a PWM that is rated for 5500W, 220V, and 25A.

Or maybe this for an SSVR:

http://www.auberins.com/index.php?main_page=product_info&cPath=53&products_id=353

My plan (a bit convoluted though it is) is to put this in line behind my SSR that runs my boil heater. That way I can still do on/off with the software, but have a way to turn the element down once I reach boil to achieve a softer boil.

[ame]https://www.youtube.com/watch?v=A-jDnFt402A[/ame]

One like this maybe?

http://www.ebay.com/itm/110v-220V-1...6c359&pid=100338&rk=11&rkt=30&sd=251251998263

I'm having a tough time finding a PWM that is rated for 5500W, 220V, and 25A.

Or maybe this for an SSVR:

http://www.auberins.com/index.php?main_page=product_info&cPath=53&products_id=353

My plan (a bit convoluted though it is) is to put this in line behind my SSR that runs my boil heater. That way I can still do on/off with the software, but have a way to turn the element down once I reach boil to achieve a softer boil.

SHvanBommel

Well-Known Member

- Joined

- Nov 5, 2007

- Messages

- 548

- Reaction score

- 57

The GPIO in the pi has PWM built in its a matter of implementation into cbpi

The GPIO in the pi has PWM built in its a matter of implementation into cbpi

Yes, but I'm not even sure this is on the roadmap. Since I don't know how to add this in myself, I need some sort of solution until then.

SHvanBommel

Well-Known Member

- Joined

- Nov 5, 2007

- Messages

- 548

- Reaction score

- 57

It is, but I think the more exposure it gets the higher it will climb on the priority list. I know Manuel is super busy but I wouldn't be surprised if it made an appearence. Fwiw on my system I use an auber dspr1. *not* the ezboil

Similar threads

- Replies

- 7

- Views

- 2K

- Replies

- 6

- Views

- 2K

- Replies

- 15

- Views

- 2K

- Replies

- 9

- Views

- 4K

Latest posts

-

-

-

-

How are You Measuring Fermentation Temperature?

- Latest: betarhoalphadelta

-

-

-

-