- Joined

- Jan 18, 2011

- Messages

- 3,039

- Reaction score

- 289

This:

and a vise will get it done fast.

OY

and a vise will get it done fast.

OY

I had a small bottle brush that I used. It cleaned up some, but there was a lot that simply wouldn't pull off. I didn't want to scratch the CPVC too much.

Band saw is what you really really want.

Wow I had not anticipated this problem. The cheap Dremel does cut through them, but it takes forever..it keeps getting caught up and stopping itself. It's not powerful enough to go through easily..so I had to sit and chip away at it. Some of my cuts looked reallly bad..they got better the longer I sat at it. I might be replacing some of the cpvpc lol.

Band saw is what you really really want.

I WISH my slits were that uniform and perfect. I'll upload a photo when I'm done, but some of them are hacked up a bit. I don't think the openings are too big, but maybe they are..

I WISH my slits were that uniform and perfect. I'll upload a photo when I'm done, but some of them are hacked up a bit. I don't think the openings are too big, but maybe they are..

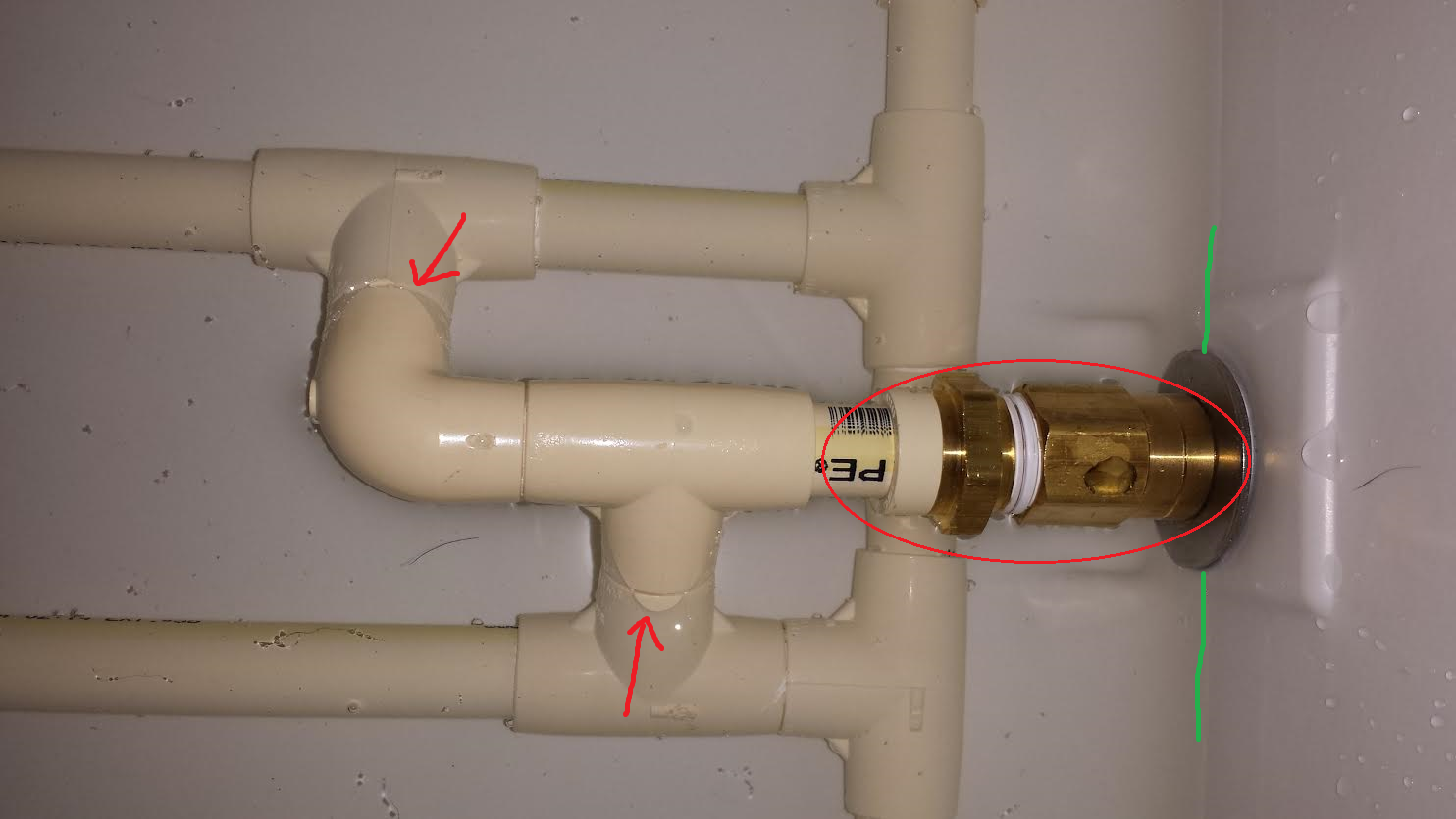

I am putting together a 48qt cooler MLT and I have the cpvc parts cut out and put together for the manifold. I want to use cpvc cement on some of the pieces and adhere them together, but I was concerned that it might have negative effects. Would I have any problems from using the cemented cpvc manifold in the mash?

I've attached a photo of the design I went with. I bought 3/8" parts for the outside and the cpvc is 1/2". I bought a brass coupler that converts 1/2" to 3/8". Could this brass piece cause any issues?

Here's a photo of the cpvc cement I got.

Thanks for looking.

Make it from copper!

I am also on final design of my cpvc system. There seems to be no way to hook the drain to the cooler drain on the same level. Reference articles say to make the slits face up or to the side. I am going to test both ways but hope that slits facing sideways will allow for more thorough drain completion of the wort.

I hope when your doing your testing.....you have a hose attached to your hose barb? If you do Not. You are not achieving a good syphon. I bet if you attach a hose to it and let the hose hang down below your valve, you'll find that it will suck almost all of the liquid out that you have left now. Your picture shows no hose.

Some liquid left is fine..over a gallon left is not fine lol. I've got my fingers crossed that this helps a lot more.About how much liquid should I expect to have left after?

Also, the outside has a small leak where the valve connects to the nipple connector at the washers. I'm currently unable to unscrew it, or I would try and add an o-ring..