- Joined

- Nov 19, 2017

- Messages

- 250

- Reaction score

- 93

I've been brewing for about 3 years now. Earlier this year I built an E-HERMS setup and have been getting pretty respectable mash efficiencies (78-85% depending on the grain bill), but I'm still seeing questionable brewhouse efficiencies.

Earlier today I brewed this recipe: http://brewgr.com/recipe/54814/cloud-city-citra-pale-ale-recipe?public=true

Pre-boil Gravity: 1.048

Pre-boil Volume: 7.8 gallons

After a 60 minute boil (1.4 gallons/hour boil off rate)...

Post-boil Gravity: 1.056

~5.7 gallons into the fermenter (I shot high to account for the double dry hop absorption).

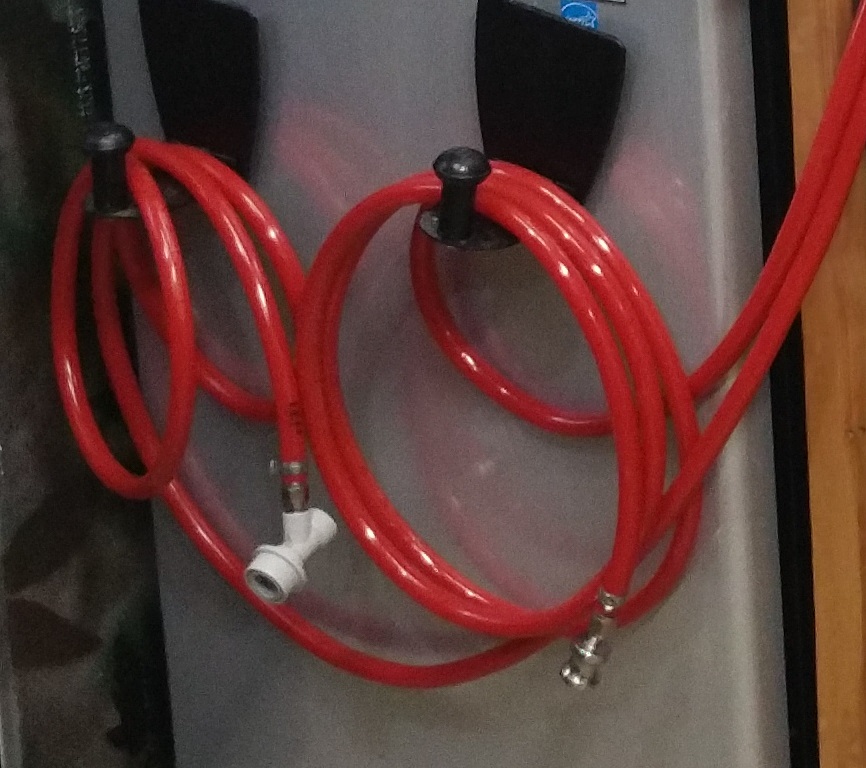

I feel like I'm losing quite a bit of volume going from the boil kettle to the fermenter. I've measured approximately ~0.5-0.6 gallons of loss between the boil kettle dead space, hoses, pump, and counterflow chiller.

Any other CFC users have the same experience? Any tips on recovering some of that volume loss? ...or is this just the price you pay with a counterflow chiller?

Earlier today I brewed this recipe: http://brewgr.com/recipe/54814/cloud-city-citra-pale-ale-recipe?public=true

Pre-boil Gravity: 1.048

Pre-boil Volume: 7.8 gallons

After a 60 minute boil (1.4 gallons/hour boil off rate)...

Post-boil Gravity: 1.056

~5.7 gallons into the fermenter (I shot high to account for the double dry hop absorption).

I feel like I'm losing quite a bit of volume going from the boil kettle to the fermenter. I've measured approximately ~0.5-0.6 gallons of loss between the boil kettle dead space, hoses, pump, and counterflow chiller.

Any other CFC users have the same experience? Any tips on recovering some of that volume loss? ...or is this just the price you pay with a counterflow chiller?