Rogue_Atom87

Well-Known Member

- Joined

- Sep 3, 2020

- Messages

- 134

- Reaction score

- 27

After getting back into this hobby and only 4 brews its time to start tinkering and upgrading equipment. Since I do small batch of roughly 2-2.5 gallon I use a 5 gallon corny keg as a fermenter. Currently I use a shortened dip tube with a screen and it works well preventing trub getting into serving keg. I also use an airlock built into gas ball lock. To date I put the keg in a keg cooler and use shock pack to keep temp low. To monitor temp I van seal a thermo pro transmitter and drop it into the fermenter. I then put receiver on top to ready temp thru the keg walls. Temps will stay between 63-68 with no issue but unable to keep it precise. I do closed transfers from keg to keg to prevent oxygen from getting introduced.

With that I wanted to add the following:

Pressure Fermentation

Thermowell

Coil to control temperature

Way to add hops, flavoring without opening up keg.

Most of the items to do this I already had on hand so with the cost of keg and to do the above I estimate total investment of around $150.

Main goal was by time I close lid for fermenting the only time beer touches air is when in the glass and this includes dry hopping and any other items need to put in beer for fermenting or rest period.

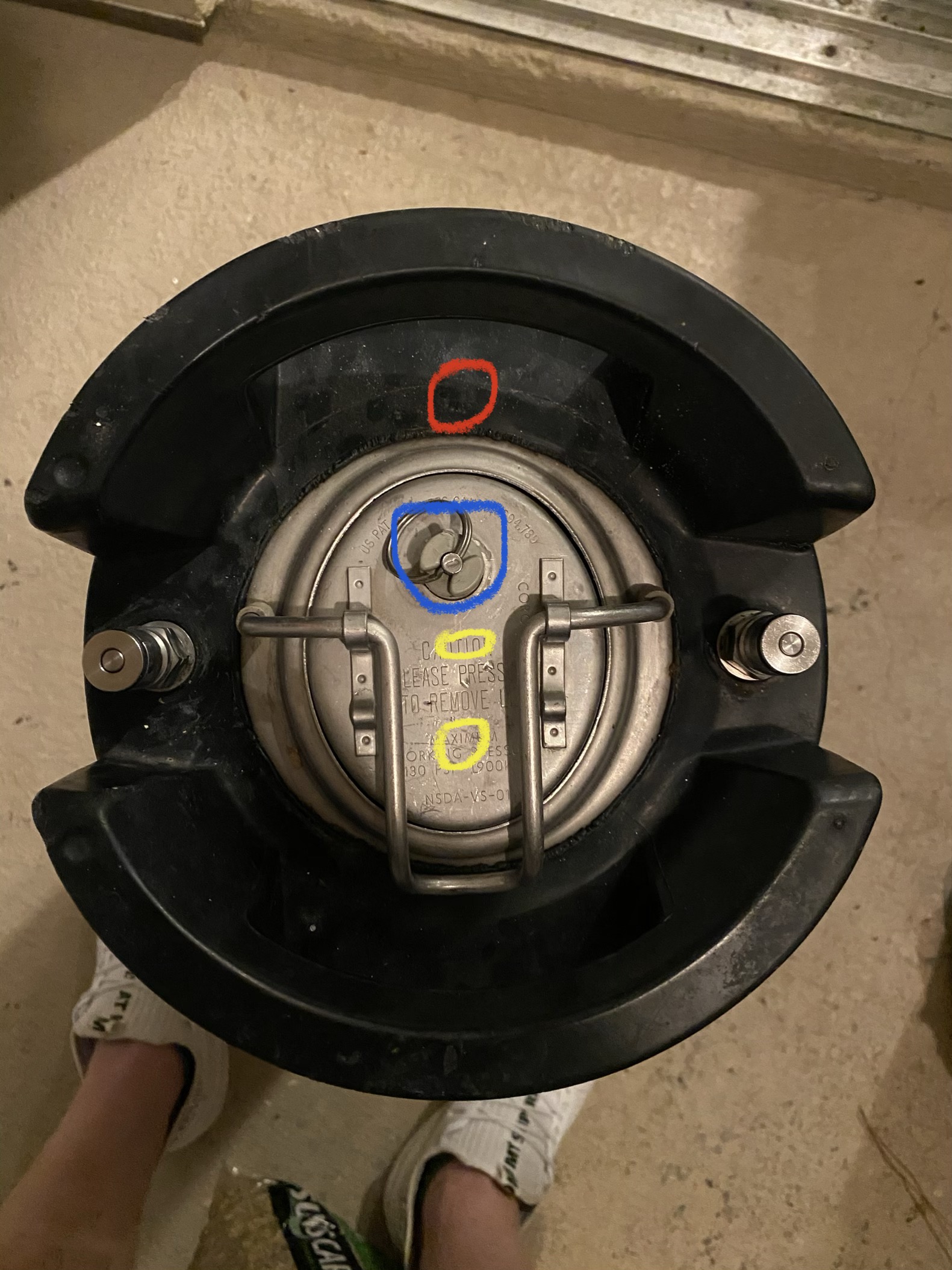

Pressure Fermentation - Bought Blowtie 2.0 with a spare gas connector. This solves pressure fermentation problem.

Thermowell - Plan was to use 1/4" copper tube sealed at one end with the cap. Use a grommet thru the lid for sealing

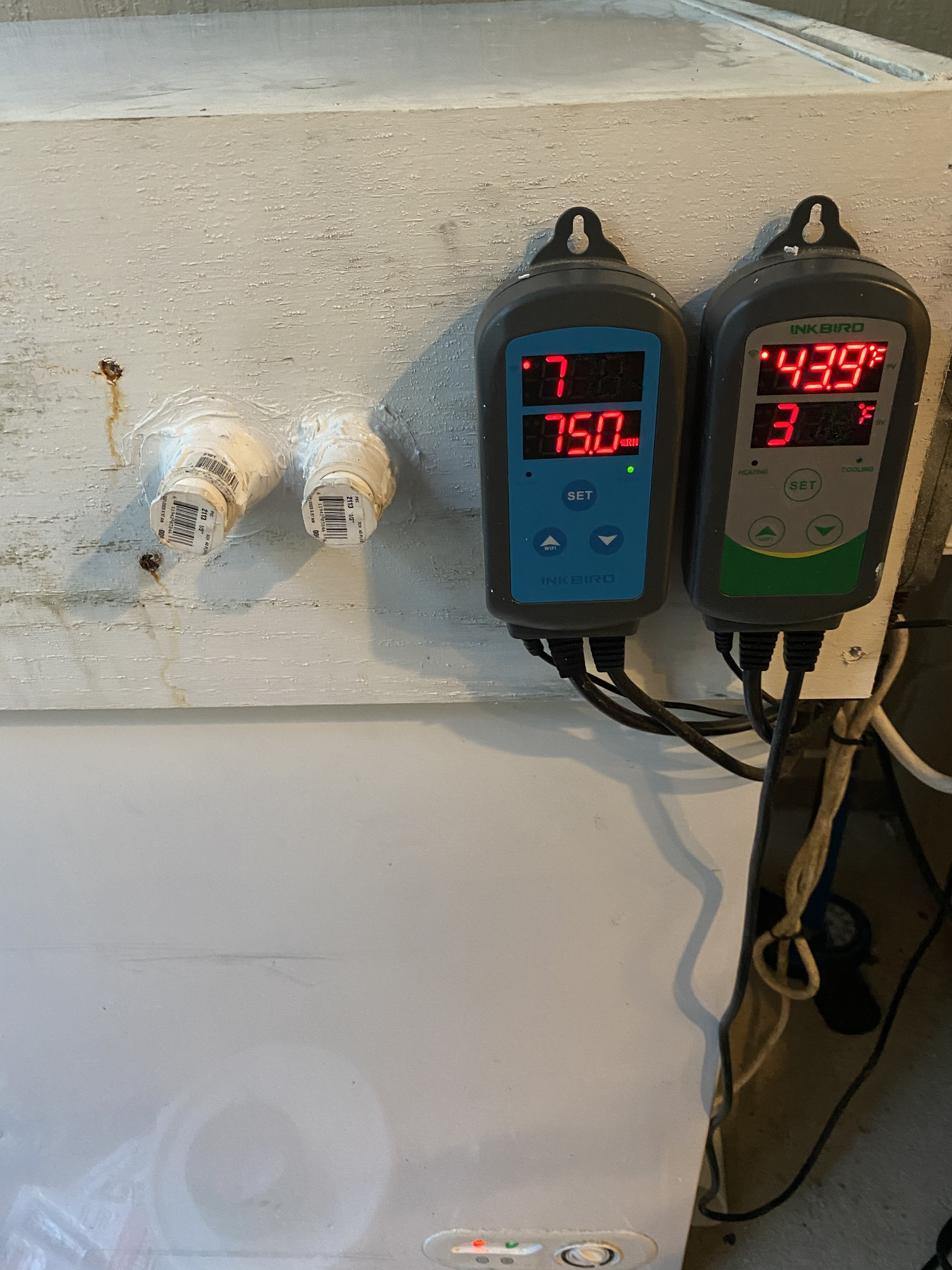

Temp Control - 3/8" copper tube ran thru grommet in the lid. I purchased another IBC that I will mount to keezer with a glycol/water bucket on inside. I am running 1/2" PVC thr keezer collar with 1/2" barbs. This way I dont have to permanently seal hoses into collar

*Here is main question on above. Are there any concerns with copper sitting in fermentation vessel for an extended period of time? If so I will convert a straight keg dip tube for thermowell but not sure how to make a cooling coil. If there a place to get 3/8" stainless tube in 10' lengths that is easy to bend? Was going to use Anvil cooling coil but doesnt go down far enough into 5gallon keg for a 2-2.5 gal batch

Dry Hopping - I purchased a 1" threaded bulkhead and a ball valve that will be connected to keg lid. I also purchased the yeast collection jar for fermzilla fermenters and will secure lid to a stainless cone. Will then add hops/flavoris/etc and secure to ball valve. Will use side port to purge with CO2 and remove all liquid. When time comes will open valve and let items fall into fermenter. Imagine will need to pressurize this a few PSI over what keg is pressure fermenting at.

Other item thought of is will the grommets thru the lid be able to withstand pressure fermentation at low PSI?

With that I wanted to add the following:

Pressure Fermentation

Thermowell

Coil to control temperature

Way to add hops, flavoring without opening up keg.

Most of the items to do this I already had on hand so with the cost of keg and to do the above I estimate total investment of around $150.

Main goal was by time I close lid for fermenting the only time beer touches air is when in the glass and this includes dry hopping and any other items need to put in beer for fermenting or rest period.

Pressure Fermentation - Bought Blowtie 2.0 with a spare gas connector. This solves pressure fermentation problem.

Thermowell - Plan was to use 1/4" copper tube sealed at one end with the cap. Use a grommet thru the lid for sealing

Temp Control - 3/8" copper tube ran thru grommet in the lid. I purchased another IBC that I will mount to keezer with a glycol/water bucket on inside. I am running 1/2" PVC thr keezer collar with 1/2" barbs. This way I dont have to permanently seal hoses into collar

*Here is main question on above. Are there any concerns with copper sitting in fermentation vessel for an extended period of time? If so I will convert a straight keg dip tube for thermowell but not sure how to make a cooling coil. If there a place to get 3/8" stainless tube in 10' lengths that is easy to bend? Was going to use Anvil cooling coil but doesnt go down far enough into 5gallon keg for a 2-2.5 gal batch

Dry Hopping - I purchased a 1" threaded bulkhead and a ball valve that will be connected to keg lid. I also purchased the yeast collection jar for fermzilla fermenters and will secure lid to a stainless cone. Will then add hops/flavoris/etc and secure to ball valve. Will use side port to purge with CO2 and remove all liquid. When time comes will open valve and let items fall into fermenter. Imagine will need to pressurize this a few PSI over what keg is pressure fermenting at.

Other item thought of is will the grommets thru the lid be able to withstand pressure fermentation at low PSI?

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)