Marshall081

Active Member

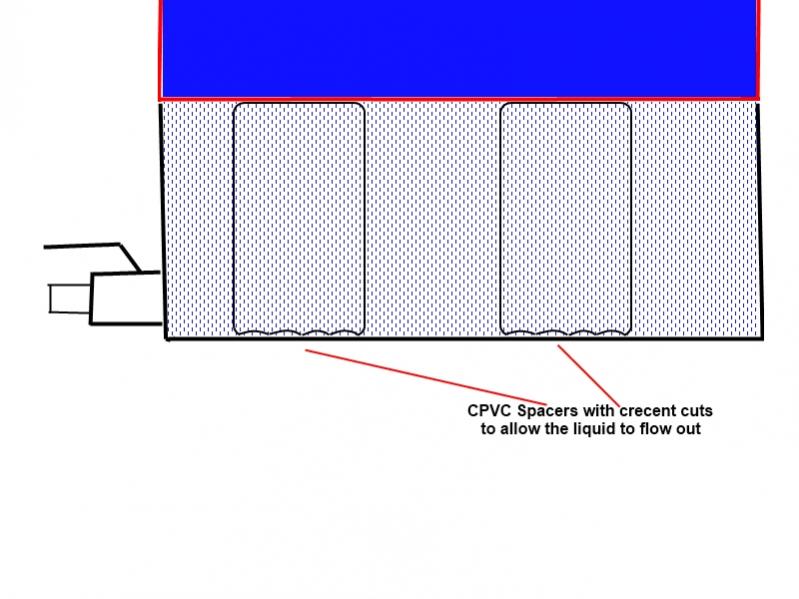

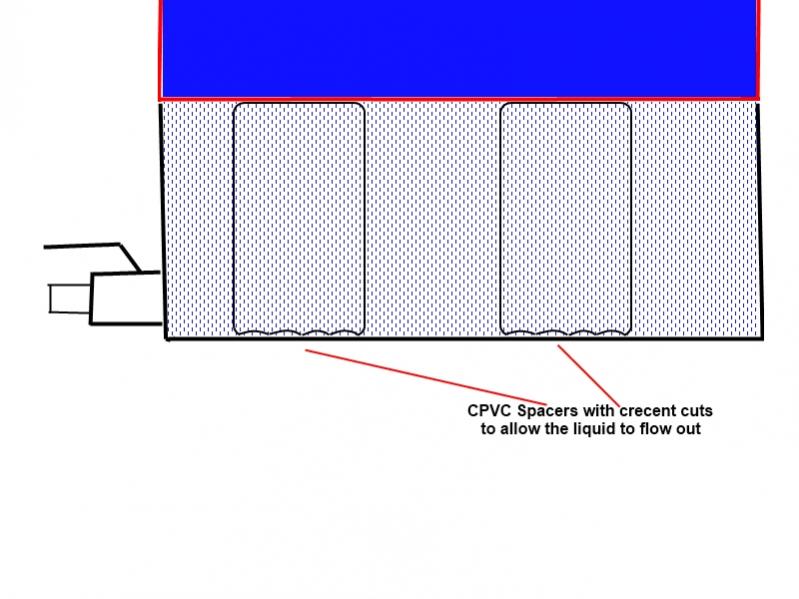

I searched the forum for a while and did not really see anything that answered my question so figured i would ask here. If I was to purchase two of the same coolers. Then cut one along the red line in the pic for example and remove the the liner , put down a few spacers in the second intact cooler to support the bottom of the cut out liner under the weight of the grain and water.(The spacers can possibly be standing vertical CVPC like in the second picture so the liquid can flow straight down and out of the bottom.) Then drill a bunch of holes in the removed cooler liner to make a plastic false bottom , would that be worth the time , money , and effort? Would it be more efficient than a manifold or bazooka screen and stainless braid type screens due to the fact that a larger surface can act as the screen?