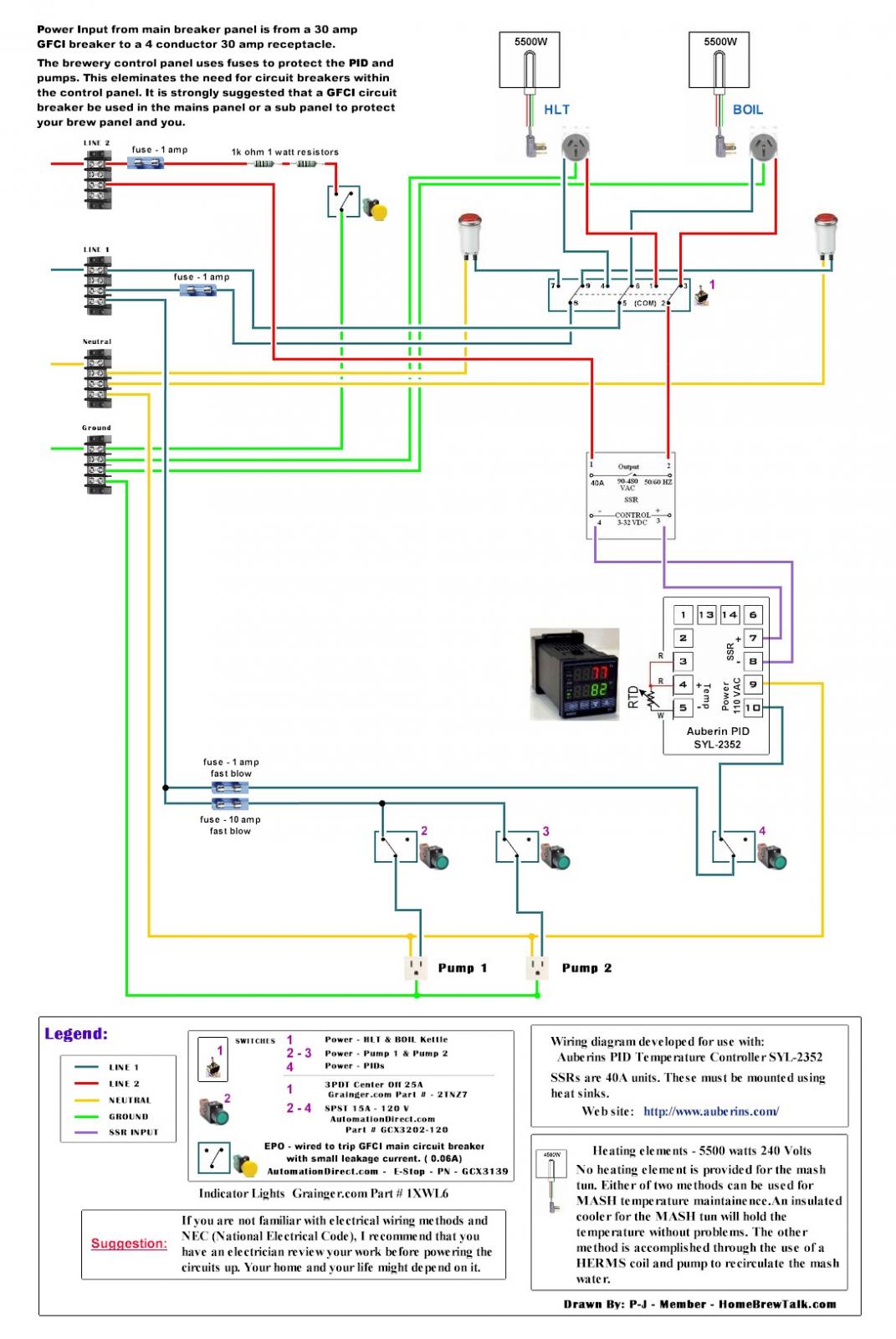

I've noticed that there are two types of control panel controls. The first is what The Electric Brewery uses, which is a lot of off-the-shelf components (PIDs, switches) integrated into a panel.

The second style is a GUI on a a single touch LCD (i.e., a tablet, phone, PC). In that case, all the controls are virtual. BCS, BrewTroller, etc are in this camp.

Which interface do you all prefer? Why? I'm re-inventing my own system and looking for experience from HBT.

The second style is a GUI on a a single touch LCD (i.e., a tablet, phone, PC). In that case, all the controls are virtual. BCS, BrewTroller, etc are in this camp.

Which interface do you all prefer? Why? I'm re-inventing my own system and looking for experience from HBT.