JONNYROTTEN

Well-Known Member

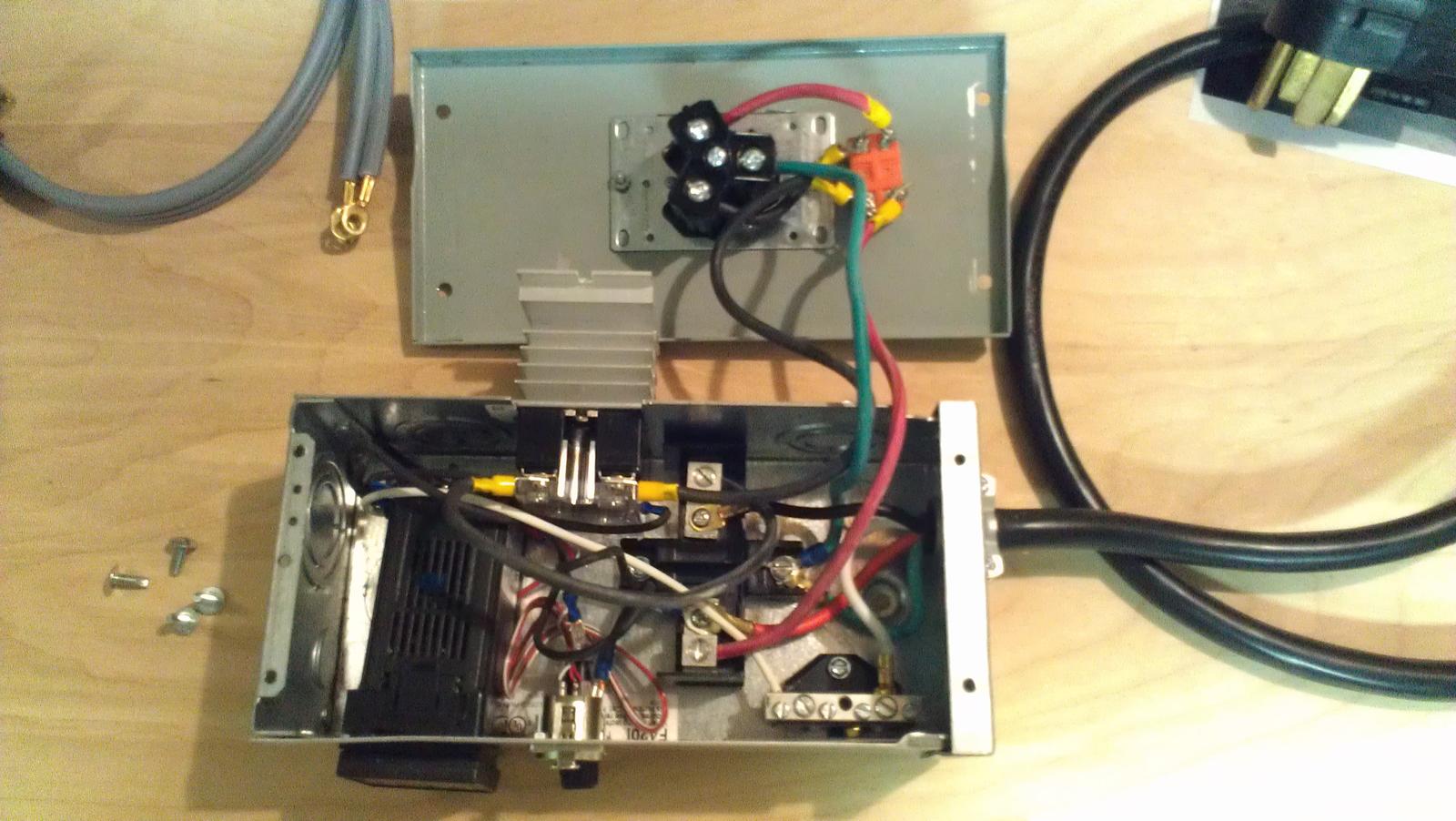

Getting back into homebrew and would like to go electric BIAB. Ive been looking at build plans and will be doing a 5500w 30A setup.Ill be hooking the element to kettle "kals way" (20 gal bayou classic)that seems simple enough. My question is with the controller.Eveyone has a different way theyre using it so every build is different.Id like to build it for around $100.With no box I have that.And no pump.

What I would like:

Temp control for mash

Temp control for boil

Boil alarm

It sounds like all I need is a pid with manual control an ssr alarm and buttons?

I just don't know which ones to buy.

Could someone help me with a parts list and is it doable for a bean

If I need buttons the light up ones look nice

What I would like:

Temp control for mash

Temp control for boil

Boil alarm

It sounds like all I need is a pid with manual control an ssr alarm and buttons?

I just don't know which ones to buy.

Could someone help me with a parts list and is it doable for a bean

If I need buttons the light up ones look nice

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)