Good morning.

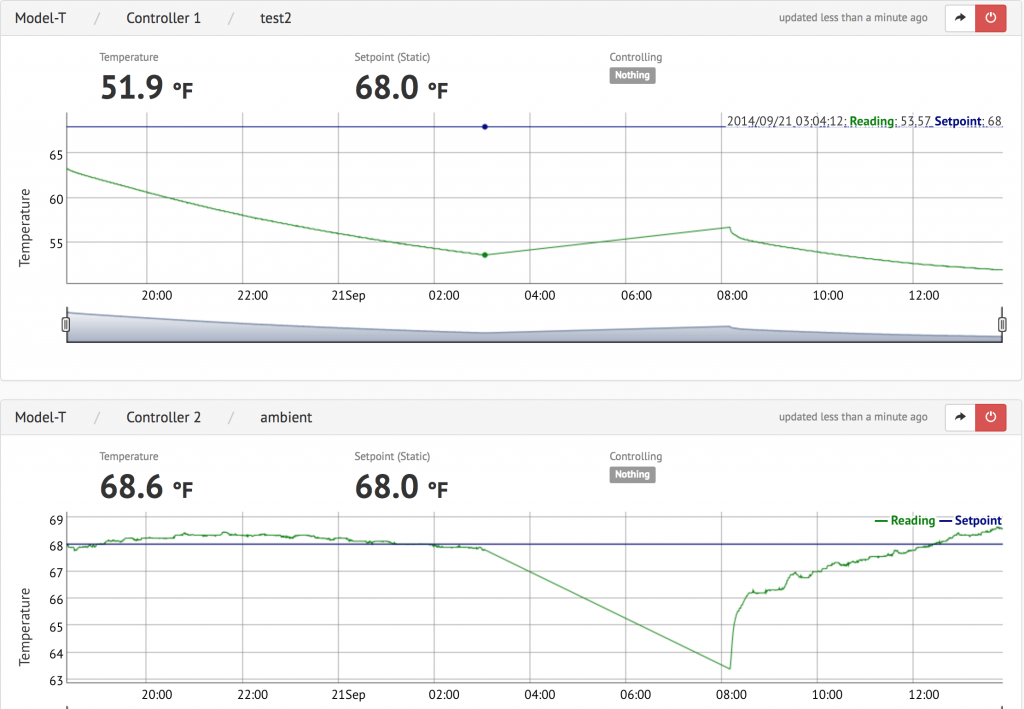

Came home from a night shift to find that the power had gone out to the conical. I plugged it back in this morning but there was about a 5 hour delay in the test, during whig time the temp rose a bit. Top of the graph shows the temp of the 6 gallons in the fermentor and the bottom graph shows ambient temperature over the night and morning. The long straight line is where no data was being sent as the power strip went out.

Looks like it is going to level out at around 50-51 degrees after about 24 hours. This is around 18-19 degrees below ambient. I may let it sit until I go to bed tonight and see if it goes any lower, but my basement never gets above 75ish, and I ferment always around 64. In other words, it works well enough for me.

As for ice forming... I do not think it is a problem for the yeast. it was a TINY bit of ice, at first I thought it was just condensation, but when I slid my finger over it, there was a thin veneer that slid to the side. And that was with no liquid in the fermentor. If there is liquid, there will be enough thermal mass that no ice should form, and the cold denser liquid should fall, starting some thermal circulation within the fermentor. This should prevent ice from ever forming when liquid is inside. But i can check after I unplug everything.

So, with a single PID, I am just at the border of being able to lager, BUT, when the beer is actively fermenting, I do not know if it will be able to deal with the extra heat of fermentation.

I tried to calculate the cooling power of the device based on the weight of the water and rate of chilling, and initially it appeared to be pulling almost exactly 40 watts of cooling power.

Klaus

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)