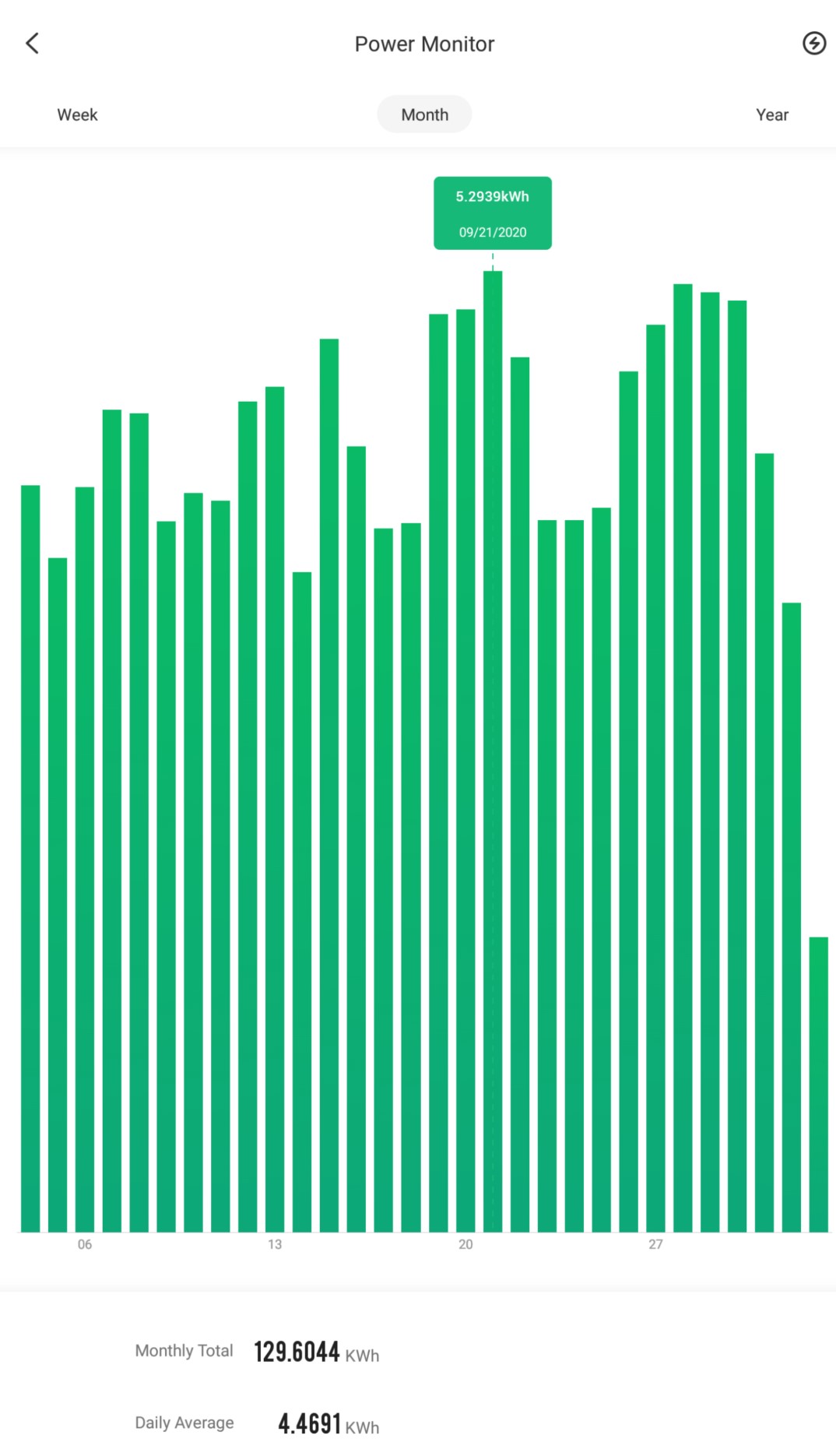

Some info on power usage:

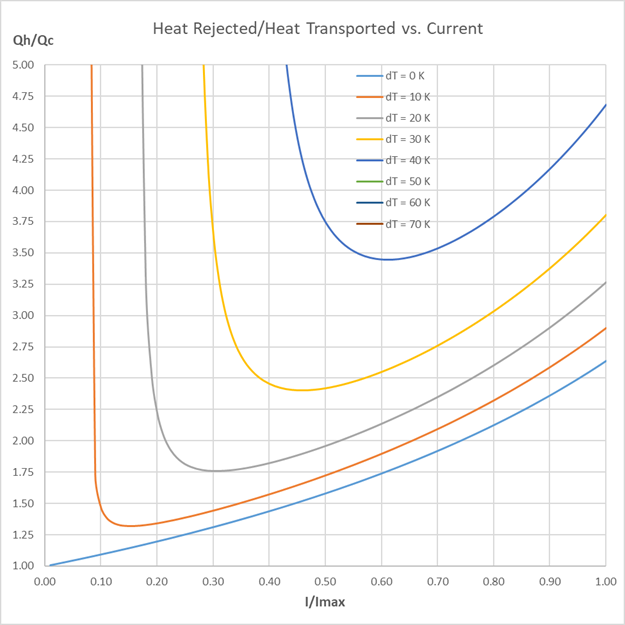

After the change to three TEC1-12715 running in series on 24V, drawing 8A, the power supply delivers 192W (from current and voltage measurement) and draws 230W (from outlet power meter); that gives a power supply efficiency of 84%. The setup used 1 kWhr in 7 hours, so that should be about 3.5 kW hours or 50 cents per day.

I'm now running a single 5 gallon keg with a set point of 6 deg C and a 2 degree deadband (cooling off at 6 C, on again at 8 C); the temperature readout fluctuations felt a bit too large to run with 1 degree deadband.

It seemed that the problem of air getting sucked into the cold loop was getting worse with the lower running temperature. The hot side does not have this problem. I assume this has to do with the plastic tubing getting less pliable as it gets colder, and sealing at the connections getting worse. I think I also lose small amounts of coolant and introduce a bit of air every time I reconnect a keg or fermenter with the quick disconnects. Therefore, instead of trying to seal all connections on the suction side of the pump, and still having to vent and refill every few quick disconnect cycles, I added a small closed reservoir inside the peltier enclosure and mounted the cold side pump in it. This vents air bubbles out of the cooling circuit every time the pump starts up (and actually continuously while it is running). It should be a while before I have to add coolant.

Some pics:

cooling enclosure with two 5 gallon kegs and a 7.5 gallon fermenter (partially visible in the front):

side view of peltier enclosure; 24V power supply on top, cold side coolant reservoir just below, with cold side pump inside:

top view; the plumbing inside looks a lot cleaner than before - the outside wiring could still use some cleanup....:

less plumbing, less wiring; the two pumps split 24V in series, and so do the three peltiers (this would not have worked with a 12V power supply); I'm monitoring one of the three 8V peltier voltages. The cold side of the peltiers uses some of the left over keg enclosure insulation (on the right). Cold (left) and hot (right) loop connections at the bottom of the picture.

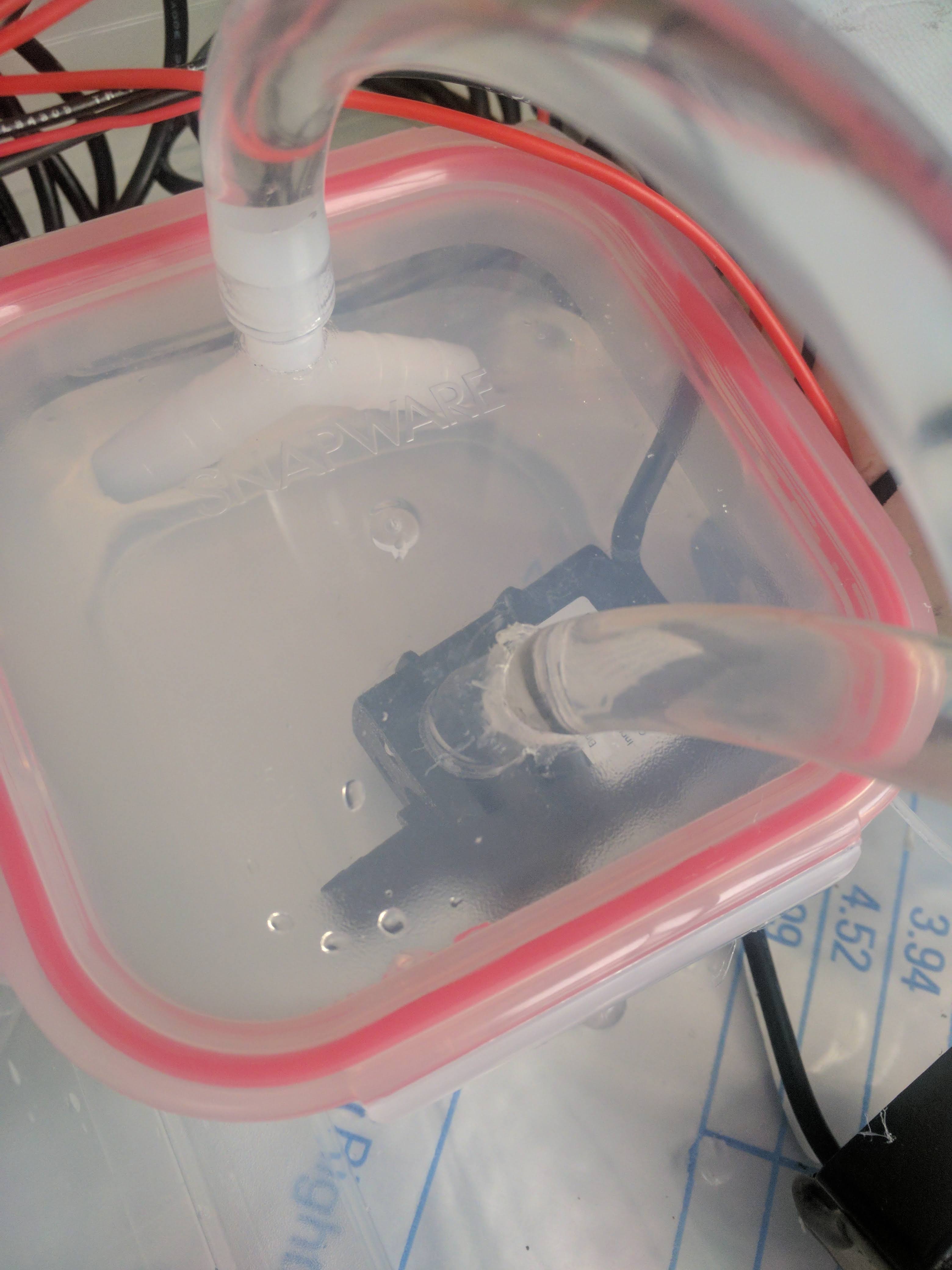

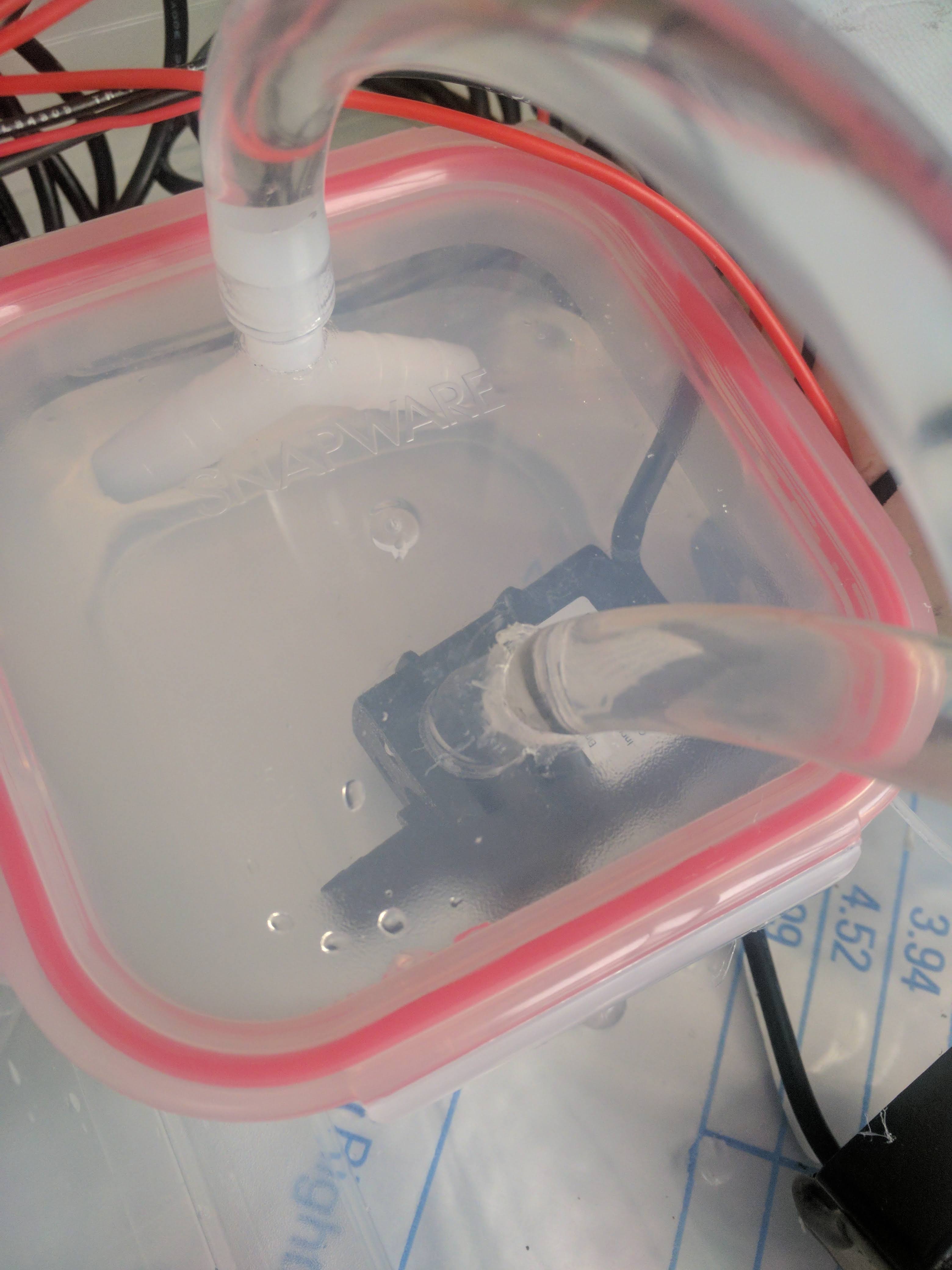

close up of the cold side coolant container; the pump output line is fed through the lid directly, the discharge line into the reservoir plugs into a barbed Y-fitting (because that is what I had left...):

After the change to three TEC1-12715 running in series on 24V, drawing 8A, the power supply delivers 192W (from current and voltage measurement) and draws 230W (from outlet power meter); that gives a power supply efficiency of 84%. The setup used 1 kWhr in 7 hours, so that should be about 3.5 kW hours or 50 cents per day.

I'm now running a single 5 gallon keg with a set point of 6 deg C and a 2 degree deadband (cooling off at 6 C, on again at 8 C); the temperature readout fluctuations felt a bit too large to run with 1 degree deadband.

It seemed that the problem of air getting sucked into the cold loop was getting worse with the lower running temperature. The hot side does not have this problem. I assume this has to do with the plastic tubing getting less pliable as it gets colder, and sealing at the connections getting worse. I think I also lose small amounts of coolant and introduce a bit of air every time I reconnect a keg or fermenter with the quick disconnects. Therefore, instead of trying to seal all connections on the suction side of the pump, and still having to vent and refill every few quick disconnect cycles, I added a small closed reservoir inside the peltier enclosure and mounted the cold side pump in it. This vents air bubbles out of the cooling circuit every time the pump starts up (and actually continuously while it is running). It should be a while before I have to add coolant.

Some pics:

cooling enclosure with two 5 gallon kegs and a 7.5 gallon fermenter (partially visible in the front):

side view of peltier enclosure; 24V power supply on top, cold side coolant reservoir just below, with cold side pump inside:

top view; the plumbing inside looks a lot cleaner than before - the outside wiring could still use some cleanup....:

less plumbing, less wiring; the two pumps split 24V in series, and so do the three peltiers (this would not have worked with a 12V power supply); I'm monitoring one of the three 8V peltier voltages. The cold side of the peltiers uses some of the left over keg enclosure insulation (on the right). Cold (left) and hot (right) loop connections at the bottom of the picture.

close up of the cold side coolant container; the pump output line is fed through the lid directly, the discharge line into the reservoir plugs into a barbed Y-fitting (because that is what I had left...):

Last edited:

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)