BrewinSoldier

Well-Known Member

- Joined

- Jul 13, 2015

- Messages

- 481

- Reaction score

- 53

Hey guys! This is the second batch of beer in a row I have ruined. The first was my fault. I forgot to pull the blow-off tube out of the sanitizer water when taking a sample and it sucked up half a mason jar or sanitizer water into my $120 batch of Pliny the Younger clone. I was sooooooooo bummed but it was my own fault. Anyways, I went to counseling and have moved past it..lol

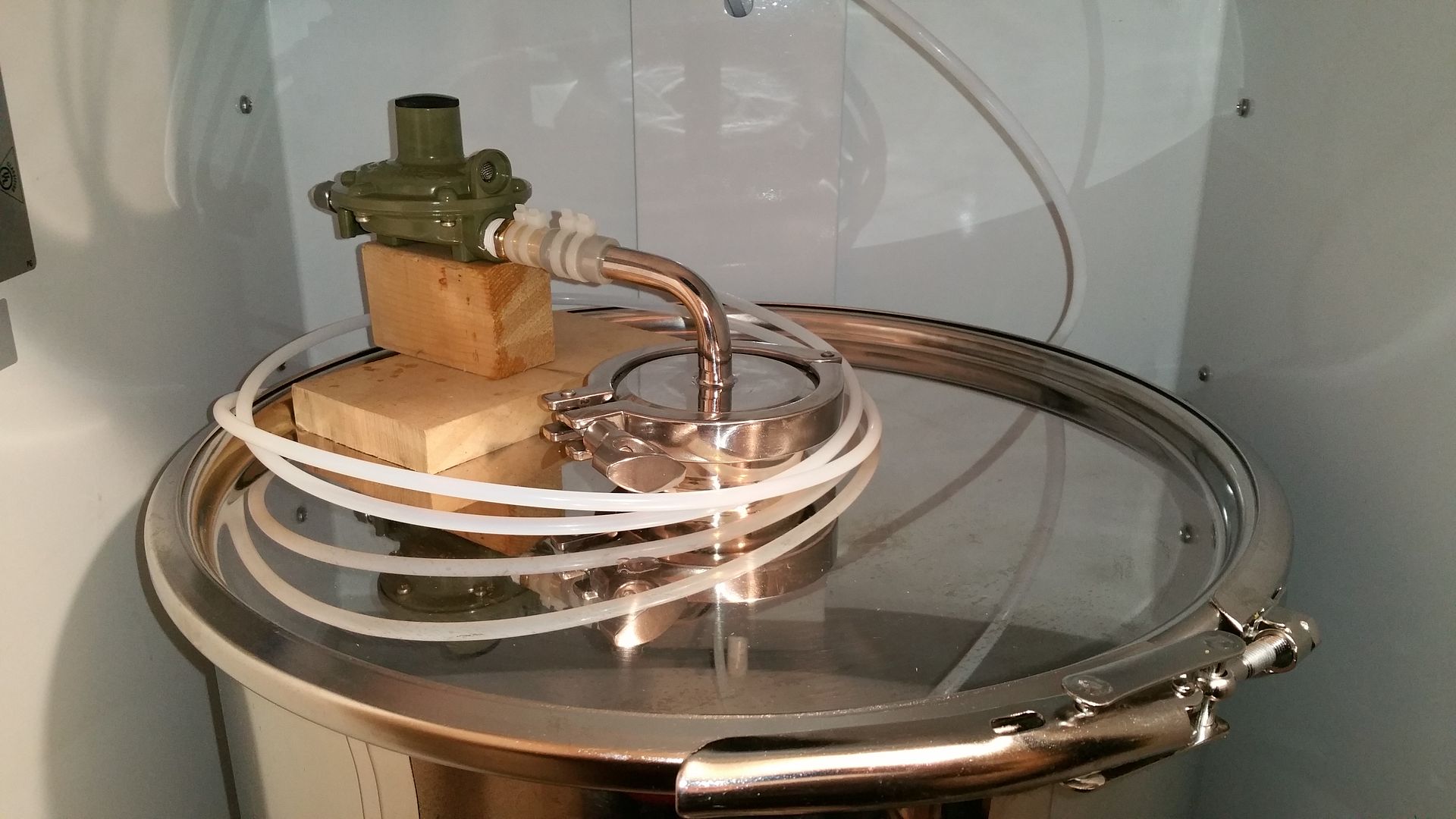

Fast forward to yesterday. I had a blueberry wheat I have been messing with the recipe on that I had in the conical. It was done fermenting so I decided it was time to crash cool it with my glycol chiller. Crank the temp down to 34 degrees around 5pm, and leave for the night. We get back at around 3am, low and behold, the damn thing sucked down a whole mason jar full of sanitizer via the blow-off tube.

How am I supposed to crash cool for 48 hours if I can't leave the blow-off tube in there? If I leave it out, it will suck in oxygen for 48 hours. The only option I can think of from now on so this doesn't happen again is to hook up a line of co2 at about 2psi so it will suck that in if it needs it rather than the oxygen.

How do you guys prevent that from happening?

Fast forward to yesterday. I had a blueberry wheat I have been messing with the recipe on that I had in the conical. It was done fermenting so I decided it was time to crash cool it with my glycol chiller. Crank the temp down to 34 degrees around 5pm, and leave for the night. We get back at around 3am, low and behold, the damn thing sucked down a whole mason jar full of sanitizer via the blow-off tube.

How am I supposed to crash cool for 48 hours if I can't leave the blow-off tube in there? If I leave it out, it will suck in oxygen for 48 hours. The only option I can think of from now on so this doesn't happen again is to hook up a line of co2 at about 2psi so it will suck that in if it needs it rather than the oxygen.

How do you guys prevent that from happening?

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)

Is it supposed to "sanitize" the air because it passes through the liquid in the lock?

Is it supposed to "sanitize" the air because it passes through the liquid in the lock?