Daniel_In_TN

New Member

I've been brewing apple cider for at least 10 years and I thought I'd share my latest and favoritest recipe. So you know where I'm going with this, I prefer a sweeter cider. When I lived in Texas, my brews were always a bit off tasting. I figured that the fermentation temperature as a bit high (75F), so I attempted to brew at 60F, a number I got from this web site. Here goes:

Cold Brew Apple/Cherry Cider

Primary

1 gallon organic apple juice.

1 cup brown sugar

Safale SA-04 yeast

Yeast nutrient

Secondary

1/2 gallon organic cherry juice

1 more cup brown sugar

Process

After sanitizing everything, tap off 1 cup of apple juice and mix it with 1 cup of brown sugar. Heat in sauce pan to over 160F to pasturize. Mix well to fully dissolve the sugar. Let cool a bit. Prove the yeast with some more of the apple juice and the nutrients. Pour juice, sugar mixture into a 1 gallon glass jug. Add yeast and put into a styrofoam box with cooling equipment. Allow to ferment at 60F for about 6 weeks.

When the fermentation has slowed down to the point where there is very little activity, it's time to bottle. Siphon the apple cider into a kettle and add the cherry juice and more pasteurized sugar mix. Mix and siphon into old Grolsch bottles with new rubbers. Let sit for a day or so at room temperature and then put in the refrigerator.

The result initially tastes like flat cherry soda pop. It has about 7-8% abv. After continuing to ferment slowly in the refrigerator, it develops quite a bit of carbonation and character. Since I drink it slowly, I like to follow the character development over the course of a month. By that time, the next batch is ready to bottle.

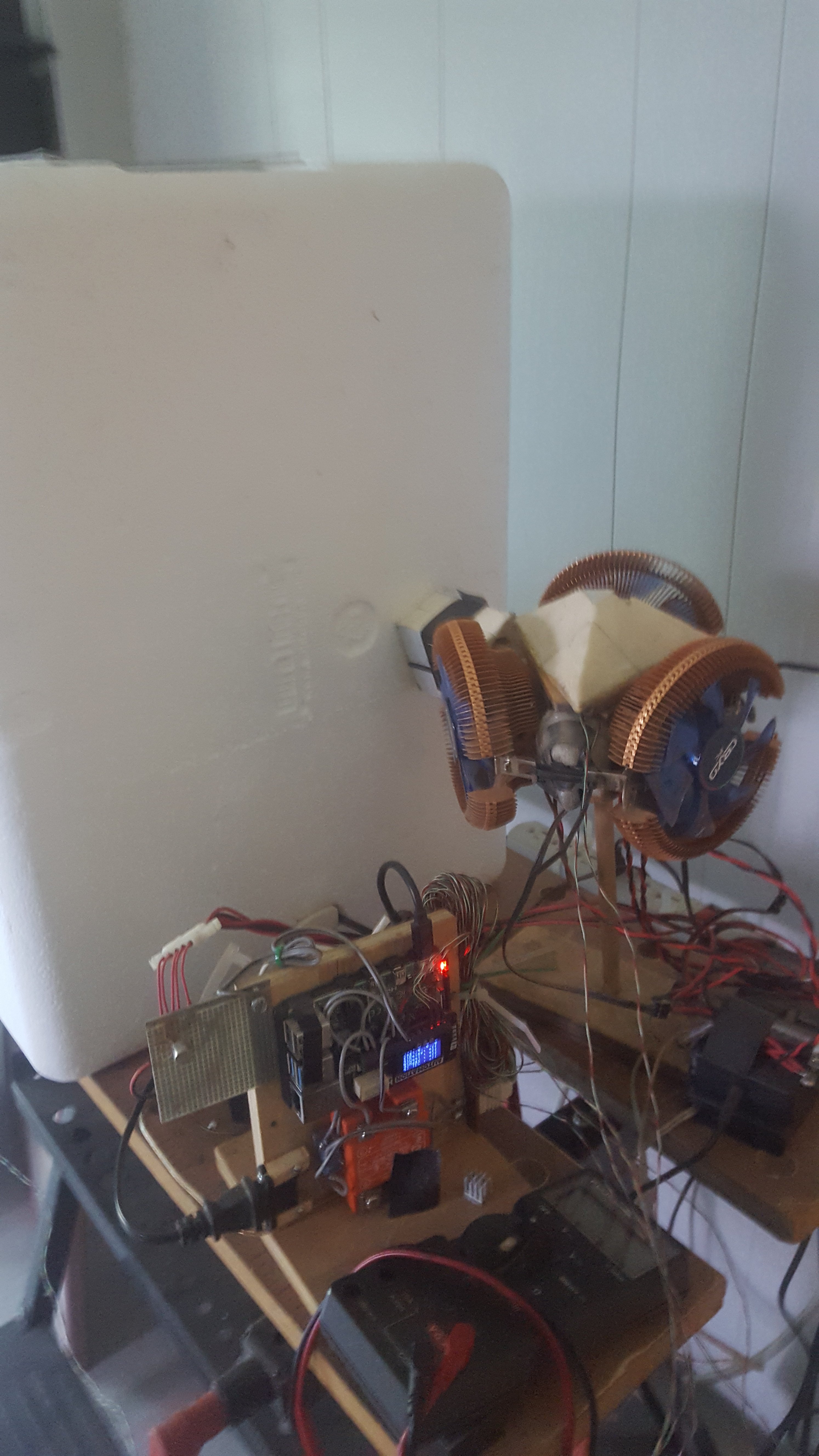

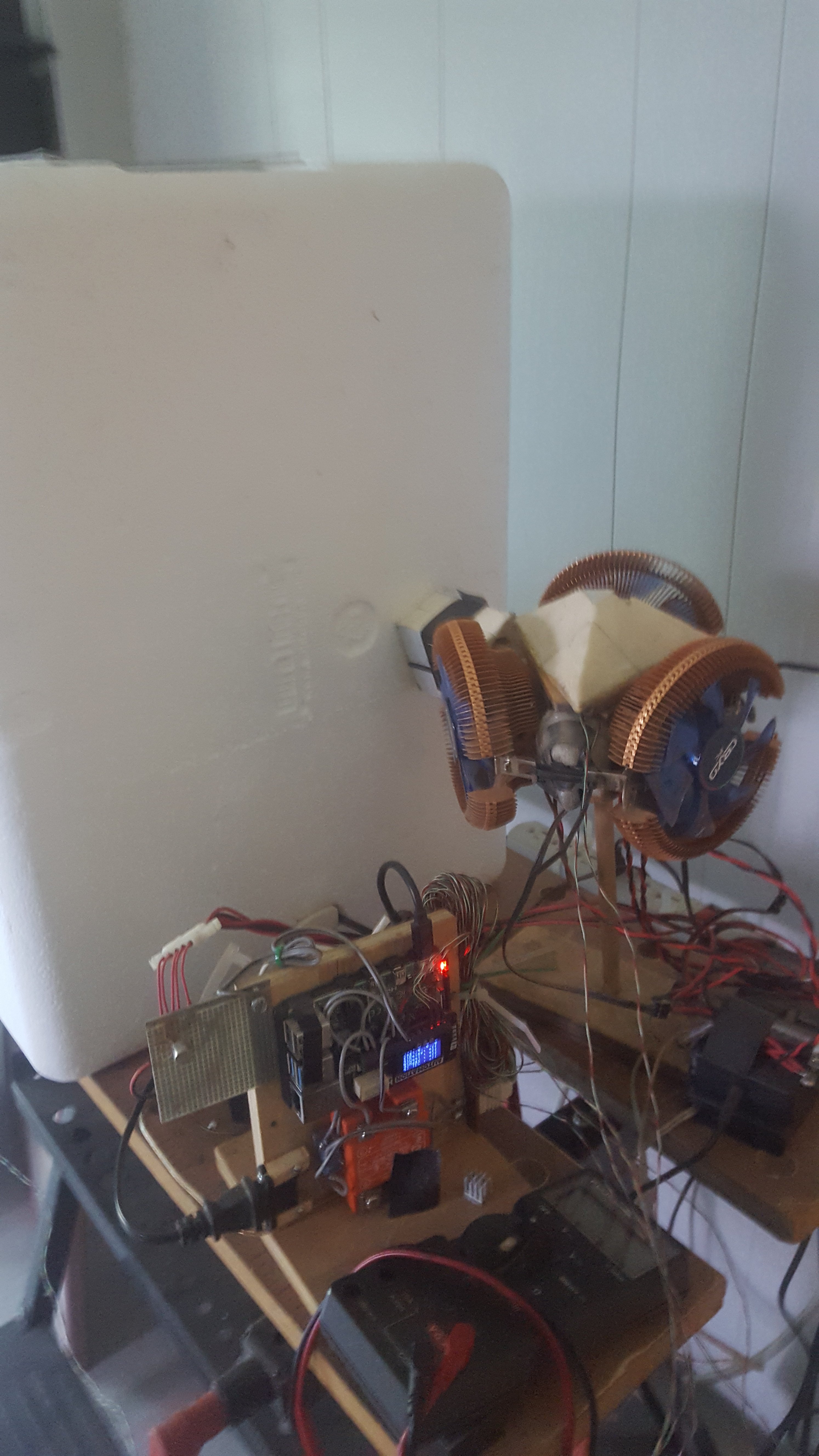

Now, I need to talk a bit about how I keep the fermentation at 60F for over a month. I started with a Styrofoam box that we received a cold shipment in and added another layer of Styrofoam to increase the insulation factor. Inside is room for a gallon jug with the trap on top alongside several loops of plastic tubing and a small submersible water pump in a reservoir of water. The pump, under computer control, pumps the water out to heat exchangers where it is cooled by Thermoelectric coolers (TECs). The water then comes back in and through the loops and back to the reservoir. A Raspberry PI monitors the temperatures of the chamber, the TECs, and the room. It turns relays on and off to hold the chamber and the TECs at whatever set-point I choose. The PI also serves a web page to my local network so I can monitor the whole process.

Cold Brew Apple/Cherry Cider

Primary

1 gallon organic apple juice.

1 cup brown sugar

Safale SA-04 yeast

Yeast nutrient

Secondary

1/2 gallon organic cherry juice

1 more cup brown sugar

Process

After sanitizing everything, tap off 1 cup of apple juice and mix it with 1 cup of brown sugar. Heat in sauce pan to over 160F to pasturize. Mix well to fully dissolve the sugar. Let cool a bit. Prove the yeast with some more of the apple juice and the nutrients. Pour juice, sugar mixture into a 1 gallon glass jug. Add yeast and put into a styrofoam box with cooling equipment. Allow to ferment at 60F for about 6 weeks.

When the fermentation has slowed down to the point where there is very little activity, it's time to bottle. Siphon the apple cider into a kettle and add the cherry juice and more pasteurized sugar mix. Mix and siphon into old Grolsch bottles with new rubbers. Let sit for a day or so at room temperature and then put in the refrigerator.

The result initially tastes like flat cherry soda pop. It has about 7-8% abv. After continuing to ferment slowly in the refrigerator, it develops quite a bit of carbonation and character. Since I drink it slowly, I like to follow the character development over the course of a month. By that time, the next batch is ready to bottle.

Now, I need to talk a bit about how I keep the fermentation at 60F for over a month. I started with a Styrofoam box that we received a cold shipment in and added another layer of Styrofoam to increase the insulation factor. Inside is room for a gallon jug with the trap on top alongside several loops of plastic tubing and a small submersible water pump in a reservoir of water. The pump, under computer control, pumps the water out to heat exchangers where it is cooled by Thermoelectric coolers (TECs). The water then comes back in and through the loops and back to the reservoir. A Raspberry PI monitors the temperatures of the chamber, the TECs, and the room. It turns relays on and off to hold the chamber and the TECs at whatever set-point I choose. The PI also serves a web page to my local network so I can monitor the whole process.