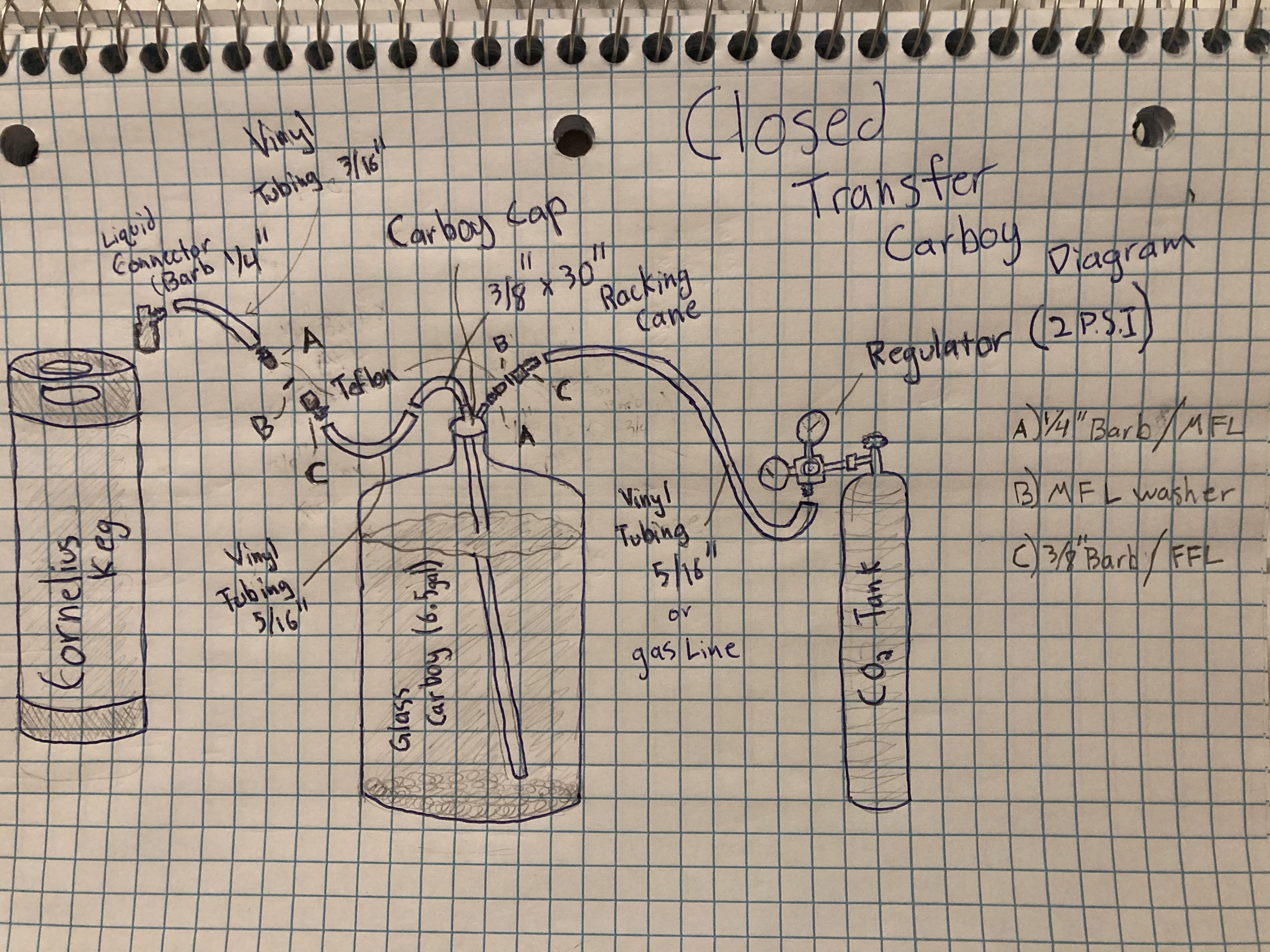

A) is a 1/4” barb x MFL

B) is a MFL washer

C) is a 3/8” barb x FFL

I saw a YouTube video from Brew n BBQ about closed transfers using a carboy, and created this rough sketch depicting my interpretation.

I wanted to know if anyone here has done this before, your successes, and if you believe this sort of setup/diagram would be feasible or work?

I want to improve my techniques, without breaking the bank. As much as Unitanks, stainless mash tuns and HLTs are awesome as hell, I’m going to have to make due with cooler HLT&MTs. However, I do wish to upgrade from plastic bucket fermentors, and wanted to get into closed transfer, hence the diagram.

Please share any thoughts!

Thanks HBT community!

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)