Golddiggie

Well-Known Member

I might need to 'buff my chillah' as soon as I get the buffing wheels/pads from my sister's basement.

Curious for those soaking: are you dropping it in, or do you rotate it to work all the air pockets out?

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)

I'm coming in late here but baking was not a good idea. Lye will lift protein but it won't remove carbon.

It's a good thing that the safety aspects of caustic were brought up. Even the traditional 1 lb per 5 gallons is dangerous, especially when hot. One of the most stated cautions is that it is anaesthetic so that if some splashes in your eyes you won't feel it as it erodes your corneas. This is untrue. It hurts like hell!

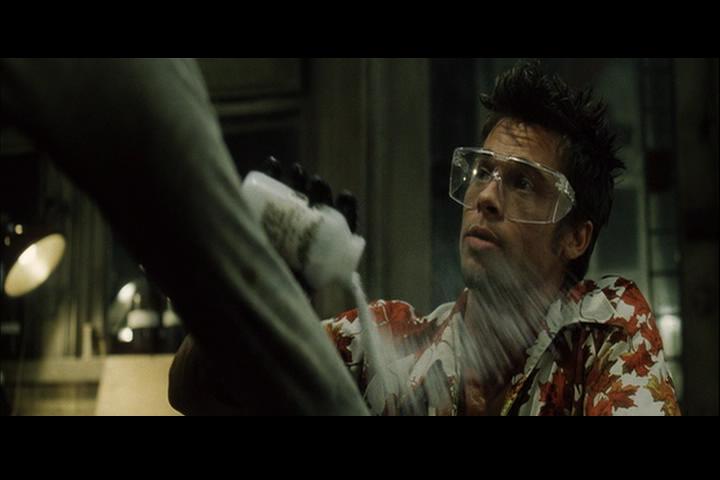

In the TV series Breaking Bad, the meth cooks are often shown sloshing around large buckets of NaOH. Sometimes (when the director is awake IMO) they are wearing protective gear, other times they are slinging the stuff into vats without any caution at all. Scared me seeing that, although I know it's just water in reality.

I'm a soapmaker, and use it in not-as-dangerous strengths, but even if a little gets on your skin it hurts like heck. It's definitely caustic, and safety googles should be worn when dealing with lye.

Don't hook a battery straight to a bucket of water! Google home electrolysis setups. They use a battery charger so you can control the current flow.