antherzoll

Member

- Joined

- Feb 24, 2013

- Messages

- 20

- Reaction score

- 7

Hello

First off, this is my first post! So hi everyone. I've been lurking for years and have always found great answers to my questions through searching, thanks for being such an awesome community. Thought I would use my first post as a contribution. I don't plan on being too active in the community, but I thought that this was worth sharing. One of my other hobbies involves me being in junkyards quite often to pick apart vehicles so that I can fix or upgrade my own. I'm also a born and raised homebrewer.

Right now I have 14 gallons of Pinot Noir that I need to degas. Usually I'd use the whip on the end of a drill but was looking into purchasing a vacuum pump... So I got thinking. Most vehicles come equipped with a vacuum assist pump with a vacuum switch. The pump is supposed to create enough vacuum to keep the brake assist functioning properly when engine vacuum is low. Somewhere around 0.5bar/15"hg. So I pulled one out of a vehicle along with the vacuum switch and a bunch of hoses to work with all for $30, only other thing required is a 12vdc 10amp power supply. The model I pull the parts from was a 2008 Volvo C30 T5, but I have seen this same setup in many other vehicles. These pumps have to operate in extreme condition so I'm sure that they are up to the task.

And I was able to create.

I'd still like to fix it up a bit, but it works! Switches on once a minute for less than a second.

What's required:

- Vacuum Assist Pump w/fittings (blue circle)

- Vaccum switch with connector and fittings (yellow circle)

- Check valve from braking circuit (green circle)

- hoses

- fittings for the carboy.

- 12VDC 10Amp Power Supply (can be purchased through amazon)

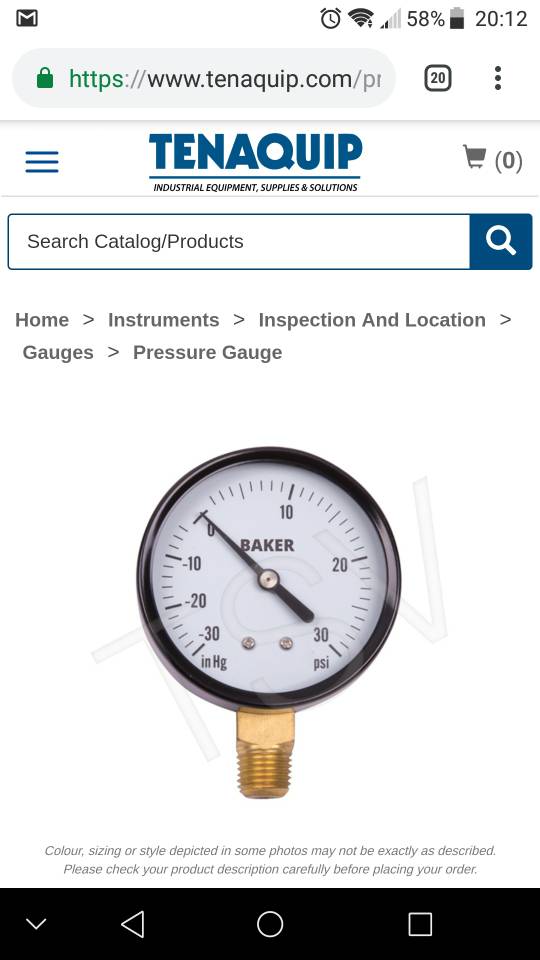

- Gauge (optional)

Pretty self explanatory. Make sure to wire the pump with the correct polarity. I plan on cleaning it up a bit and installing a fuse just because, but for now it's working well. Let me know what you all think.

Cheers

First off, this is my first post! So hi everyone. I've been lurking for years and have always found great answers to my questions through searching, thanks for being such an awesome community. Thought I would use my first post as a contribution. I don't plan on being too active in the community, but I thought that this was worth sharing. One of my other hobbies involves me being in junkyards quite often to pick apart vehicles so that I can fix or upgrade my own. I'm also a born and raised homebrewer.

Right now I have 14 gallons of Pinot Noir that I need to degas. Usually I'd use the whip on the end of a drill but was looking into purchasing a vacuum pump... So I got thinking. Most vehicles come equipped with a vacuum assist pump with a vacuum switch. The pump is supposed to create enough vacuum to keep the brake assist functioning properly when engine vacuum is low. Somewhere around 0.5bar/15"hg. So I pulled one out of a vehicle along with the vacuum switch and a bunch of hoses to work with all for $30, only other thing required is a 12vdc 10amp power supply. The model I pull the parts from was a 2008 Volvo C30 T5, but I have seen this same setup in many other vehicles. These pumps have to operate in extreme condition so I'm sure that they are up to the task.

And I was able to create.

I'd still like to fix it up a bit, but it works! Switches on once a minute for less than a second.

What's required:

- Vacuum Assist Pump w/fittings (blue circle)

- Vaccum switch with connector and fittings (yellow circle)

- Check valve from braking circuit (green circle)

- hoses

- fittings for the carboy.

- 12VDC 10Amp Power Supply (can be purchased through amazon)

- Gauge (optional)

Pretty self explanatory. Make sure to wire the pump with the correct polarity. I plan on cleaning it up a bit and installing a fuse just because, but for now it's working well. Let me know what you all think.

Cheers

Last edited:

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)