So I’m struggling here. I know to trust the Manometer on the tank, but even with my co2 regulator higher than desired(20psi vs. 12psi desired) I’m not seeing the manometer increase much. Should this take a while?

Process:

Add head pressure through blow off to 10psi reading on manometer.

Set co2 reg to 18 psi and attach to ssb carb stone.

Monitor until manometer reads 12psi and then remove co2.

Problem: have not seen any change in manometer reading in 24 hours.

This is what works best for me. I have the 1/2 barrel SSBT unitank.

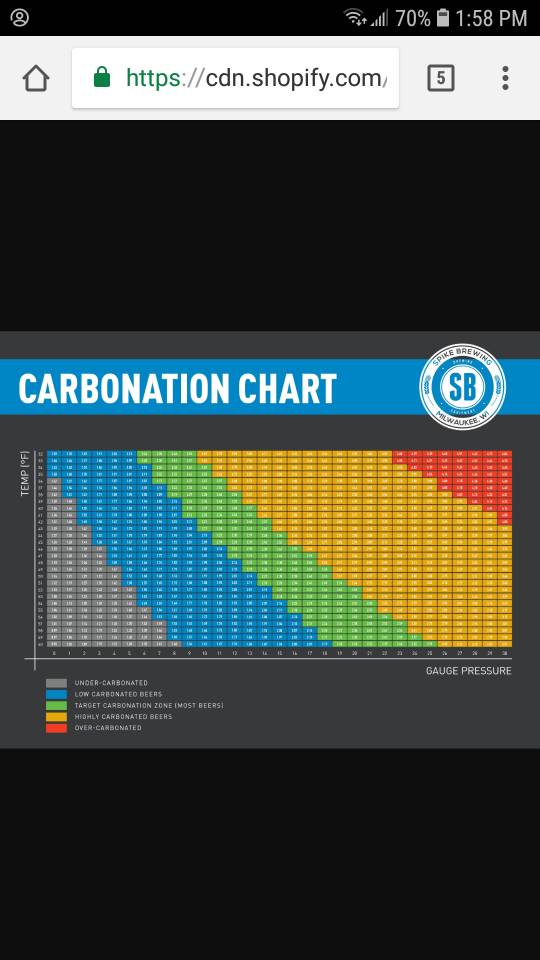

You'll want to find the "wetting" pressure of your carb stone and determine the volume of beer in the unitank above the carb stone (add approx. 1 PSI for every 28 inches of liquid). Add these numbers to your desired CO2 volume from the chart. This is what you will set your regulator pressure to. For instance, my process is this;

If I'm shooting for 12.5 CO2, I set the head pressure in the unitank to 12 PSI (head pressure forces the gas from the stone to remain in solution instead of bubbling through and possibly stripping away aroma), connect the gas to the carb stone and set the regulator to 18.5 PSI. This accounts for:

1. Desired CO2 volume of 12.5

2. My stone's wetting pressure of 5

3. Volume of beer over the carb stone 1

12.5 + 5 + 1 = 18.5

NOTE: If you are in an area of high altitude you will need to add additional PSI to compensate. You can search the web for that.

Also, if you have a flow meter to control the flow rate of CO2 that helps as well but, not mandatory.

Once the CO2 in solution rises above the 12 PSI it will then increase the head pressure. Keep checking the manometer on the tank until it starts to rise. Once it reaches 12.5 you know you have equilibrium between the CO2 in solution and the head pressure, shut off gas, you're done. I usually let it sit for a while and recheck the pressure, taste the beer and adjust if needed. This process has worked great for me. I can usually fully carb a beer in about 5 to 6 hours.

To determine your stone's wetting pressure:

1. Remove the stone from the tank

2. Connect it to gas

3. Submerge the stone in a bucket of starsan

4. Slowly increase the gas pressure until the stone is putting out fine bubbles of CO2 into the liquid

5. Note the pressure on the gauge, this is your stone's wetting pressure (the amount of pressure need just to get gas to flow through the stone)

Hope that helps!

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)