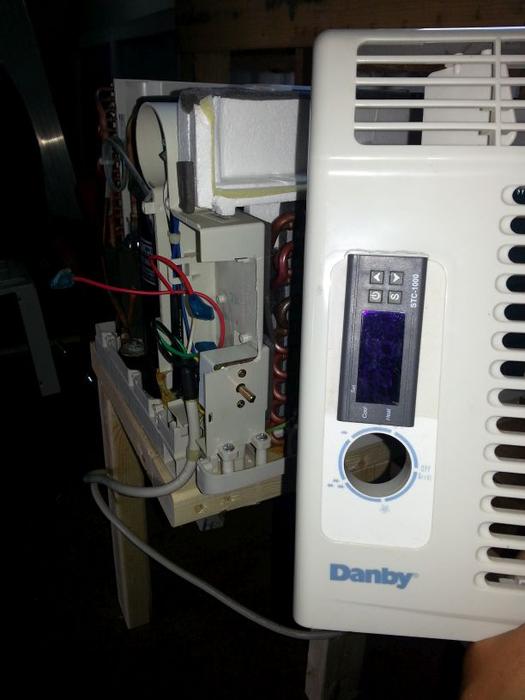

Can STC-1000 really source 10A (heat and cool) long term? I'm thinking of using it to control a small air conditioning unit for my ferm chamber. The ac units says that it will draw a little over 5A. Do you think I will be okay using only the stc-1000's built in relay's, or should I just have the stc-1000 control a pair of external 15A relays to be safe?

Thanks

Thanks

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)