You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Brutus Style Brewstand Build

- Thread starter BrewingGunner

- Start date

Help Support Homebrew Talk:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

BrewingGunner

Well-Known Member

Gotcha! Thanks.

BrewingGunner

Well-Known Member

Ok, the burners came in today. I plan to attach them tomorrow and then paint it up. I can't decide wether to make my own mounts and wind screens, or just weld the whole system to the frame? I bought the KAB4 from Amazon. I'm leaning towards just welding the whole system to the rig. Thoughts?

HDIr0n

Well-Known Member

I would weld the whole thing so you have a wind shield and less work.

BrewingGunner

Well-Known Member

HDIr0n said:I would weld the whole thing so you have a wind shield and less work.

That's what I'm planning. I'll just grind some of the paint and weld it on. Built a stir plate too.

BrewingGunner

Well-Known Member

Meant to work on this over the weekend, but I am sick as a dog.

$719.00

$799.00

EdgeStar KC2000TWIN Full Size Dual Tap Kegerator & Draft Beer Dispenser - Black

Amazon.com

$10.99 ($31.16 / Ounce)

Hornindal Kveik Yeast for Homebrewing - Mead, Cider, Wine, Beer - 10g Packet - Saccharomyces Cerevisiae - Sold by Shadowhive.com

Shadowhive

$53.24

1pc Hose Barb/MFL 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304(Liquid Hose Barb)

Guangshui Weilu You Trading Co., Ltd

$7.79 ($7.79 / Count)

Craft A Brew - LalBrew Voss™ - Kveik Ale Yeast - For Craft Lagers - Ingredients for Home Brewing - Beer Making Supplies - (1 Pack)

Craft a Brew

$53.24

1pc Hose Barb/MFL 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304(Liquid MFL)

yunchengshiyanhuqucuichendianzishangwuyouxiangongsi

$176.97

1pc Commercial Keg Manifold 2" Tri Clamp,Ball Lock Tapping Head,Pressure Gauge/Adjustable PRV for Kegging,Fermentation Control

hanhanbaihuoxiaoshoudian

$22.00 ($623.23 / Ounce)

AMZLMPKNTW Ball Lock Sample Faucet 30cm Reinforced Silicone Hose Secondary Fermentation Homebrew Kegging joyful

无为中南商贸有限公司

$20.94

$29.99

The Brew Your Own Big Book of Clone Recipes: Featuring 300 Homebrew Recipes from Your Favorite Breweries

Amazon.com

$58.16

HUIZHUGS Brewing Equipment Keg Ball Lock Faucet 30cm Reinforced Silicone Hose Secondary Fermentation Homebrew Kegging Brewing Equipment

xiangshuizhenzhanglingfengshop

$27.29 ($13.64 / Count)

$41.99 ($21.00 / Count)

2 Pack 1 Gallon Large Fermentation Jars with 3 Airlocks and 2 SCREW Lids(100% Airtight Heavy Duty Lid w Silicone) - Wide Mouth Glass Jars w Scale Mark - Pickle Jars for Sauerkraut, Sourdough Starter

Qianfenie Direct

$39.22 ($39.22 / Count)

Brewer's Best Home Brew Beer Ingredient Kit - 5 Gallon (Mexican Cerveza)

Amazon.com

lpdjshaw

Well-Known Member

Where'd you get those from? I like 'em!

Also where did you get that hose? Price and is it good at boiling temps?

BrewingGunner

Well-Known Member

I got some work done today. Attached one burner, will attach the other tomorrow. Then I have to sand the surface rust so I can paint it.

BrewingGunner

Well-Known Member

Burners are attached! Now to remove the surface rust and paint!

BrewingGunner

Well-Known Member

Finally got the stand ground down and painted. I'll do a test run tomorrow with pictures. Tip to all paint this as quickly as possible. These things rust quick and they are a pain to prep.

BrewingGunner

Well-Known Member

Casters on the way. If the rain stops tomorrow, I'll attach the pumps and light the burners.

BrewingGunner

Well-Known Member

I am just waiting on the casters, but I tested the burners and pumps. Brewing on it this weekend let me know what y'all think of it.

BrewingGunner

Well-Known Member

That stuff is coming in Monday. I'm brewing on it Saturday anyway.

BrewingGunner

Well-Known Member

Inaugural brew day with the stand.

BrewingGunner

Well-Known Member

Casters are on. Did a little touch up paint. Pumps back on tomorrow and then I'll be waiting for your thoughts!

BrewingGunner said:Casters are on. Did a little touch up paint. Pumps back on tomorrow and then I'll be waiting for your thoughts!

Looks good!! I need to catch up!!

BrewingGunner

Well-Known Member

It was fun to build but more fun to brew on. Let me know if you want plans.

GoodDogShelby

Well-Known Member

Nice looking stand. Did you find that your burners are too far away from the kettles? I did something similar with my Bayou Classics. I cut the legs off and used the wind screen / burner mount. I mounted the rings to angle iron supported by all thread. That lets me adjust the position of the burner.

Rivenin

Well-Known Member

- Joined

- Dec 13, 2010

- Messages

- 3,258

- Reaction score

- 342

Looking great! thats the same way i did mine (with the shields/burners)

one thing though, i would put the windscreens higher, or drill holes and mount the burners higher. you have a welder so you can do this easier. I did that on mine and increased times rather nicely = much less wasted propane

basically i had cut the legs off and welded the screens to the stand itself.

kind of like this if you dont want to cut the legs off.

hopefully that helps somewhat on the times! shouldn't take longer then an hour or two.

Keep us updated though! looking great! (PS. i have the same welder. for $100, it's kick ass )

)

one thing though, i would put the windscreens higher, or drill holes and mount the burners higher. you have a welder so you can do this easier. I did that on mine and increased times rather nicely = much less wasted propane

basically i had cut the legs off and welded the screens to the stand itself.

kind of like this if you dont want to cut the legs off.

hopefully that helps somewhat on the times! shouldn't take longer then an hour or two.

Keep us updated though! looking great! (PS. i have the same welder. for $100, it's kick ass

)

)BrewingGunner

Well-Known Member

Looking great! thats the same way i did mine (with the shields/burners)

one thing though, i would put the windscreens higher, or drill holes and mount the burners higher. you have a welder so you can do this easier. I did that on mine and increased times rather nicely = much less wasted propane

basically i had cut the legs off and welded the screens to the stand itself.

kind of like this if you dont want to cut the legs off.

hopefully that helps somewhat on the times! shouldn't take longer then an hour or two.

Keep us updated though! looking great! (PS. i have the same welder. for $100, it's kick ass)

Thanks! I think I'll look into drilling the holes first in the windscreen and see how that works!

On a different note, where did you get the control box with the switch? It looks perfect to power the pumps!

BrewingGunner

Well-Known Member

That i built.

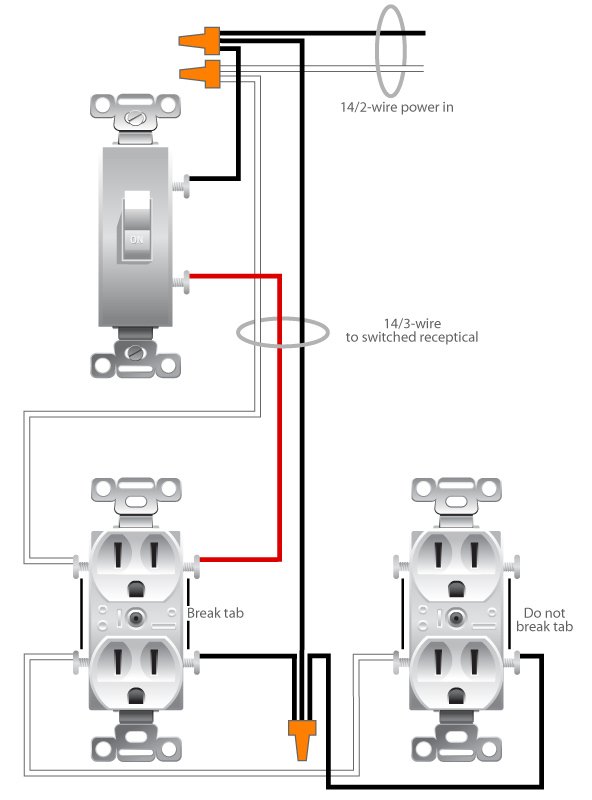

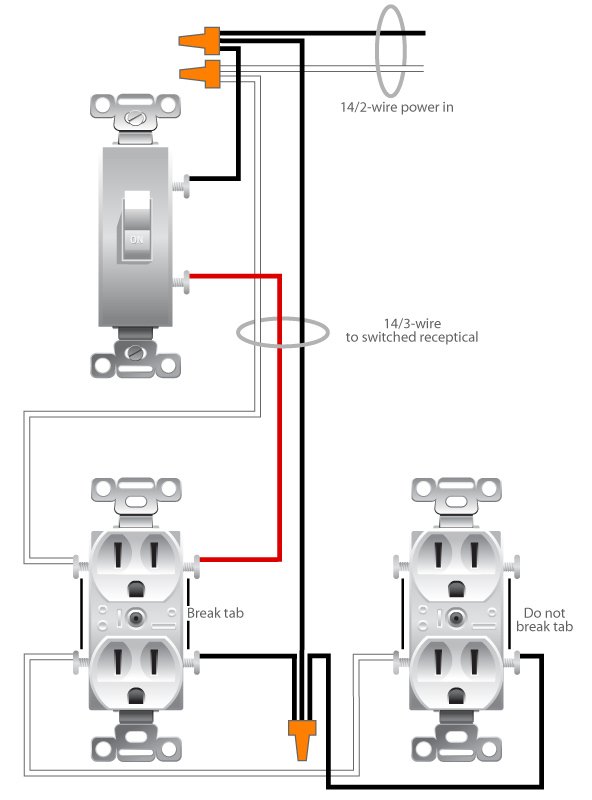

Here is the diagram, i just went to Lowes and picked up the waterproof stuff (i think all together it was about $15 or so, and the extension cord was i think $5, well worth it)

Thanks so much. I'll look for that stuff today. I'm tired of plugging and unplugging the pumps to turn them on/off. The enclosure was at lowes too?

BrokenDog

Well-Known Member

That i built.

Here is the diagram, i just went to Lowes and picked up the waterproof stuff (i think all together it was about $15 or so, and the extension cord was i think $5, well worth it)

I just finished my single tier 3 burner with 2 pumps the other day and want to wire in a waterproof box to plug in each pump without cutting the cord and each have their own switch. I see in the diagram I see you have 2 outlets, 1 for each pump but only switch, am I missing something?

BrewingGunner

Well-Known Member

Nice looking stand. Did you find that your burners are too far away from the kettles? I did something similar with my Bayou Classics. I cut the legs off and used the wind screen / burner mount. I mounted the rings to angle iron supported by all thread. That lets me adjust the position of the burner.

It works pretty well. I'm going to try and drill some holes further up and move it about an inch close to the kettles and see if that's even better.

Rivenin

Well-Known Member

- Joined

- Dec 13, 2010

- Messages

- 3,258

- Reaction score

- 342

Thanks so much. I'll look for that stuff today. I'm tired of plugging and unplugging the pumps to turn them on/off. The enclosure was at lowes too?

Indeed!

Here is the cover

http://www.lowes.com/pd_78997-223-E...uctId=3799389&Ns=p_product_qty_sales_dollar|1

and here is the back box

http://www.lowes.com/ProductDisplay...gId=10051&cmRelshp=rel&rel=nofollow&cId=PDIO1

With that digram, i ignored the right hand outlet. And if you wire it up that way, it basically will give constant power to one and the switched source will be the other. it actually comes in handy that way

I just finished my single tier 3 burner with 2 pumps the other day and want to wire in a waterproof box to plug in each pump without cutting the cord and each have their own switch. I see in the diagram I see you have 2 outlets, 1 for each pump but only switch, am I missing something?

that diagram is one i pulled off the net with the original switch build, i ignored the one on the right and basically one is switched and one has constant power (if i have a light or anything i just plug it into that one)

I can help you wire something up pretty easy if you're looking for that though!

Shoot me a PM with what you're looking to specifically do and i'll do a little diagram for ya

it'll help get by work today (i have really nothing to do.... lol)

it'll help get by work today (i have really nothing to do.... lol)Rivenin

Well-Known Member

- Joined

- Dec 13, 2010

- Messages

- 3,258

- Reaction score

- 342

well here is 2 different ways to wire the switch.

If you wire it on the LEFT side, it has the top switched and the bottom constant.

if you wire it on the RIGHT diagram, you will have both being switched by the switch.

Let me know if this all makes sense

If you wire it on the LEFT side, it has the top switched and the bottom constant.

if you wire it on the RIGHT diagram, you will have both being switched by the switch.

Let me know if this all makes sense

BrokenDog

Well-Known Member

It sounds like running the switched and constant outlet together would be the most versatile option, although I can't think what I would use it for atm. So if I were to want 2 pumps on 2 switches going into on box with just one power supply line coming in, what would that look like? I guess I would have to look to see what these watertight boxes look like, I just can't picture what how the outlets would be mounted to keep everything dry with 2 plugs coming in, 1 out and 2 switches.

Rivenin

Well-Known Member

- Joined

- Dec 13, 2010

- Messages

- 3,258

- Reaction score

- 342

Well one idea is this.

http://www.lowes.com/pd_78998-223-E...uctId=3135247&Ns=p_product_qty_sales_dollar|1

take that plate, wire in 2 switches and have 2 corded ends coming out of it that you can plug into from your pumps. you wouldn't have a constant in that circumstance (unless you wanted another dongle coming out of it) and those project type boxes. Or you can hardwire your pumps... anything is really possible and not very expensive.

However, if you wanted to build off of a project type box, anything is possible. And that i can help with easily as well, just the enclosure is not going to be prebuilt like those boxes. I can make a wiring diagram like the one posted above for you as well if you have some ideas?

so we don't bunch up his thread too much, PM me with some ideas and i can get something together for ya!

http://www.lowes.com/pd_78998-223-E...uctId=3135247&Ns=p_product_qty_sales_dollar|1

take that plate, wire in 2 switches and have 2 corded ends coming out of it that you can plug into from your pumps. you wouldn't have a constant in that circumstance (unless you wanted another dongle coming out of it) and those project type boxes. Or you can hardwire your pumps... anything is really possible and not very expensive.

However, if you wanted to build off of a project type box, anything is possible. And that i can help with easily as well, just the enclosure is not going to be prebuilt like those boxes. I can make a wiring diagram like the one posted above for you as well if you have some ideas?

so we don't bunch up his thread too much, PM me with some ideas and i can get something together for ya!

Similar threads

- Replies

- 12

- Views

- 3K

- Replies

- 9

- Views

- 2K

- Replies

- 4

- Views

- 4K

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)