I decided to tackle a stand myself even though I can't weld, or couldn't weld when I started. I used Lonnie's Brutus 10 plans and made them a bit longer to accommodate the SABCO kegs I have.

I used 2" x 2" x .120" mild steel so that I would have something to tap for the gas lines, pumps etc... I did not trust myself enough to build the gas beam.

The burners I got from Northern Brewer, sheds and valves from Brewers Hardware and misc pipe etc... from Lowes. The plate chiller is from duda.

I am still debating on adding some stainless stand offs to help dissipate the gasses from the bottom of the stand. I probably should have thought of that first.

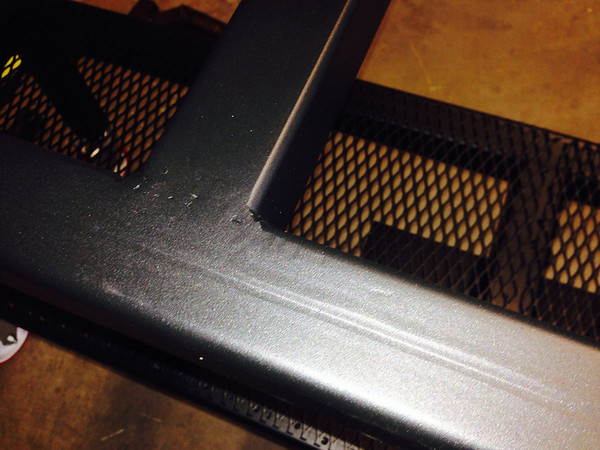

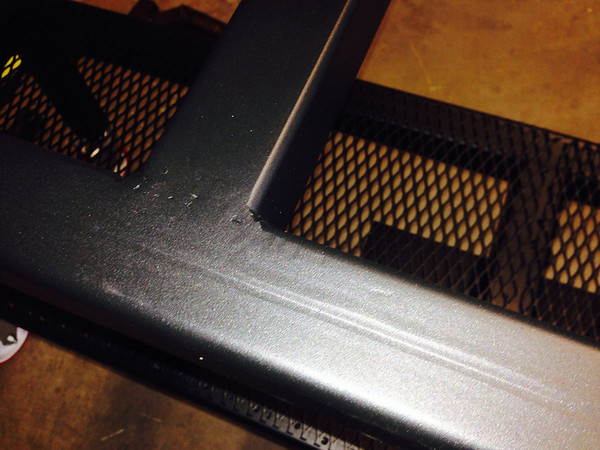

The stand was coated with a high temperature ceramic coating. I still need to hard wire the pumps to a switch but it should be ready for a test run soon.

I used 2" x 2" x .120" mild steel so that I would have something to tap for the gas lines, pumps etc... I did not trust myself enough to build the gas beam.

The burners I got from Northern Brewer, sheds and valves from Brewers Hardware and misc pipe etc... from Lowes. The plate chiller is from duda.

I am still debating on adding some stainless stand offs to help dissipate the gasses from the bottom of the stand. I probably should have thought of that first.

The stand was coated with a high temperature ceramic coating. I still need to hard wire the pumps to a switch but it should be ready for a test run soon.