[...]Weyermann probably has the best protection due to their inner liner[...]

I totally agree, their bag is the best of any I've handled. I wish everyone used it

Cheers!

[...]Weyermann probably has the best protection due to their inner liner[...]

Brew day went well, other than the crush being too fine for false bottom, everything worked as it should. Found out that a cheap 5 inch stainless kitchen sieve works OK for false bottom, no issues with stuck mash or grist in pump, if anything percolation was better than average.

Color is what one would expect for a good pils malt, extraction a little better than average. I got about 1.060 starting gravity out of 20#s for approx 10+ gallons of wort. That is on the normal to high side of efficiency for my rig. Wort tastes good, no reason to believe it will not beer really good beer.

I don't see why this won't keep fairly well in sealed bags. It is shipped in a sack that is two heavy layers of paper, and one of plastic. I guess it might not store as well as un milled malt over long term, but am not too worried about it.

I really like the way you wrote this recipe, a bit long for a haiku but poetic nonetheless. I'm going to try this myself when I get my hands on some malt gems....a Blonde Ale using 89% base grain with the remainder split equally with carapils and 20L crystal. The rest of the bill is 28 IBUs of Citra, Mosaic and Galaxy and a pitch of Imperial 09 Pub yeast.

Thanks for the update I was worried about the packaging as all I can see right now is the outer most paper sack. Glad to hear there is more to it I’ll stick with my plan to open one sack at a time, brew, and put remains in gamma seal lidded buckets. My rig uses NorCal false bottom and a wilser bag with continous recirc. This grain sounds perfect for me excited to try it out.Brew day went well, other than the crush being too fine for false bottom, everything worked as it should. Found out that a cheap 5 inch stainless kitchen sieve works OK for false bottom, no issues with stuck mash or grist in pump, if anything percolation was better than average.

Color is what one would expect for a good pils malt, extraction a little better than average. I got about 1.060 starting gravity out of 20#s for approx 10+ gallons of wort. That is on the normal to high side of efficiency for my rig. Wort tastes good, no reason to believe it will not beer really good beer.

I don't see why this won't keep fairly well in sealed bags. It is shipped in a sack that is two heavy layers of paper, and one of plastic. I guess it might not store as well as un milled malt over long term, but am not too worried about it.

I'll be brewing with MaltGems tomorrow, starting out simple and basic: a Blonde Ale using 89% base grain with the remainder split equally with carapils and 20L crystal.

A BIAB bag in a three vessel mash tun is a real game changer.

Sorry to hear you had so much trouble.

I had clear wort too. I found percolation good during fly sparge and vorlauf, though I would have had pump clogging problems if I had tried to use my normal false bottom.

No mash cap or hot side Lodo here, just old fashion 3 vessel fly sparge, though I do underlet the strike water, because it is easier. During sparge I keep at least a gallon on top of grist until the the end, this might help grain bed stay loose.

Your rig sounds complicated to me, but sounds like you have it dialed in, the fine crush just not a good fit.

Anyway, I ordered another 50#, since it is so inexpensive and I was impressed with flavor, and I already broke the handle off the kitchen strainer.

My other options for false bottom were a big china cap I have w some old resturaunt gear, or window screen wired on the false bottom. Glad I spotted the strainer before I went with one of those, though they may have worked OK too.

A BIAB bag in a three vessel mash tun is a real game changer.

I think maximizing tun volume is pretty much the point of this product...

Cheers!

I tapped into the beer from the 100% test batch of this malt on 8/9. Made with my standard mash, which is 20# grist with a 6.5 gallon strike and 9.5 gallon fly sparge for 10+ gallons finished beer. Fermented with US-05 at 65F, hopped to around 28 IBUs plus a hop step with leaf cascade at around 160F, came out around 6.5% ABV.

Visually, it has not cleared as much as I would have expected after being crashed for over 2 weeks at 30F, despite addition of whirlflock in same procedure I always use that usually results in clear beer. I have my suspicion that this malt is resonsible for the haze, at least in its interaction with my rig & process. If this is the case, this might be an good base malt for making hazy styles of beer, but not so good for crisp, clear ones.

The flavor is good, moderately malty with a fresh flavor, was expecting to be able to taste the alcohol more, but there is enough flavor that it is not forward. There is a lack of "bite" in finish which I'm guessing is the result of the relative absence of hulls. While this is touted as a good thing in malt description, it almost tastes like something is missing to me, but I have to think about it to notice.

A batch of rye "cream ale" I made with 50% of this malt has been crashed for 5 days. I'll be looking to see if the haziness is repeated. I'll compare to the batch I made just before the 100% test batch with the same recipe, but with fresh milled Viking pils, which is crystal clear.

The wort in the test batch was quite clear also, which is why I'm a little surprised the beer did not clear up more by now. I checked the written log I keep during brew days, and I did add the wirlflock.

That is about the same clarity as mine. Usually my brews come out clearer. Had some of the 50% batch this evening, brewed two weeks ago, crashed 5 days, is good, but also not clear.

If anyone knows what property in this pre milled, sifted and hull removed malt would make it more cloudy, I'd like to know. I'm guessing something about protein, or changed pH due to lack of hulls, or maybe a little bit of hull tannen helps with clarity.

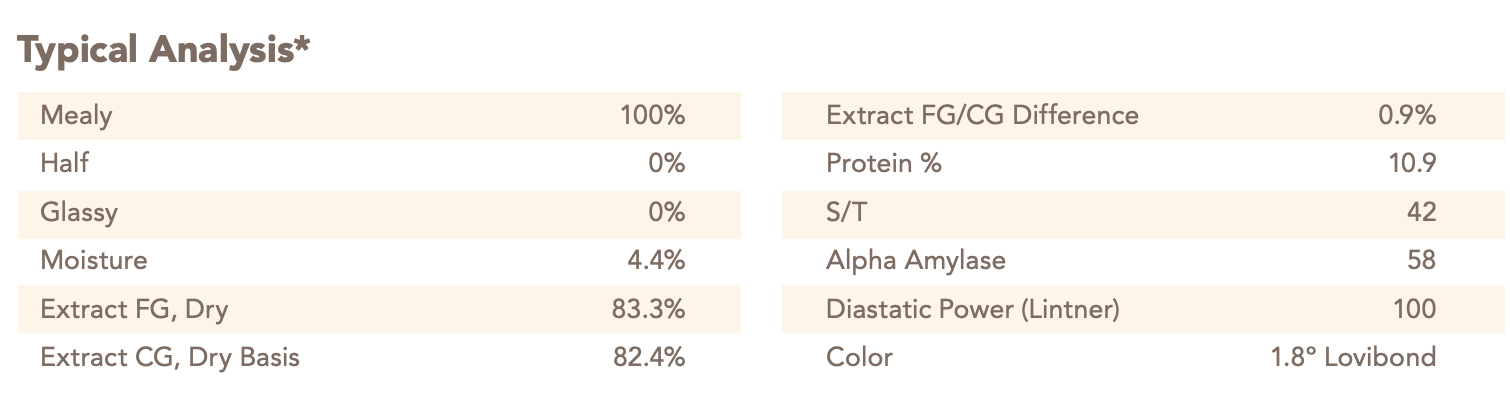

Have you guys noticed the data sheet for the malt gems and plain versions of Briess Synergy Select Pilsen Malt include identical statistics. Don't understand how this can be true.

https://www.brewingwithbriess.com/Assets/PDFs/Briess_PISB_SynergySelectPilsen.pdfTYPICAL ANALYSIS*

Mealy / Half / Glassy ................................................... 100% / 0% / 0%

Plump ........................................................................................................... 98%

Thru ................................................................................................................. 0%

Moisture .................................................................................................... 4.4%

Extract FG, Dry Basis ........................................................................ 83.3%

Extract CG, Dry Basis ....................................................................... 82.4%

Extract FG/CG Difference ................................................................ 0.9%

Protein ......................................................................................................... 10.9

S/T .................................................................................................................... 42

Alpha Amylase............................................................................................. 58

Diastatic Power (Lintner) ..................................................................... 100

Color ........................................................................................ 1.8º Lovibond

https://maltgems.brewingwithbriess.com/documents/2020_SynergySelectMaltGems_SS_5-21-20.pdfView attachment 697066