BraxtonBrewery

Well-Known Member

- Joined

- Sep 6, 2008

- Messages

- 104

- Reaction score

- 7

Time for an update!!

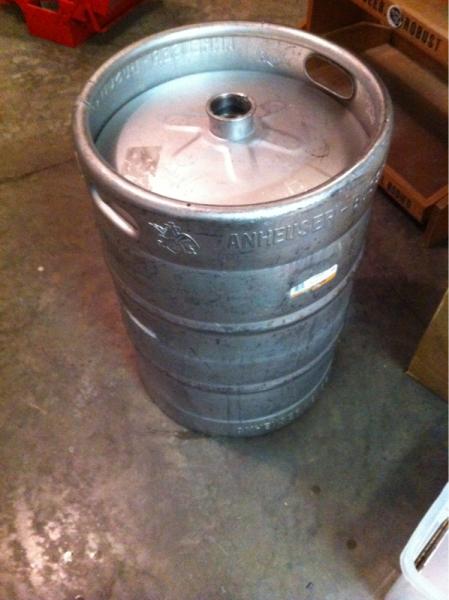

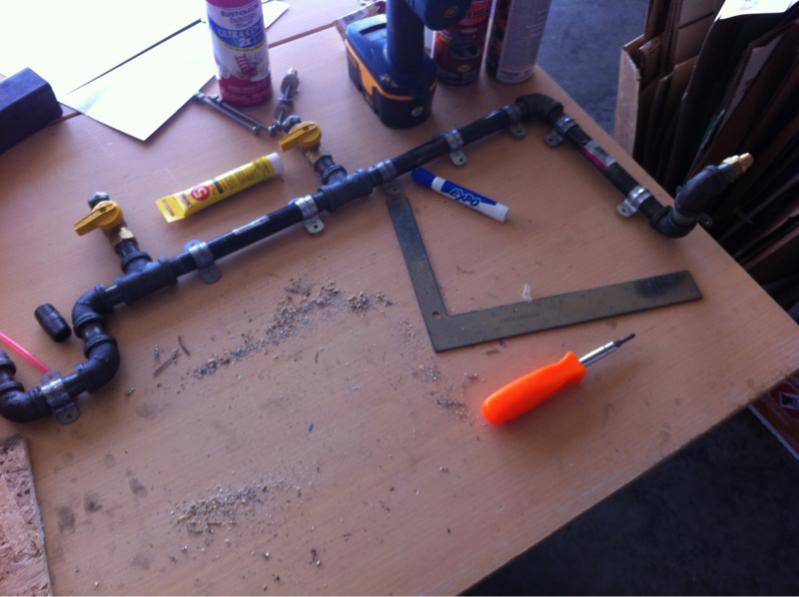

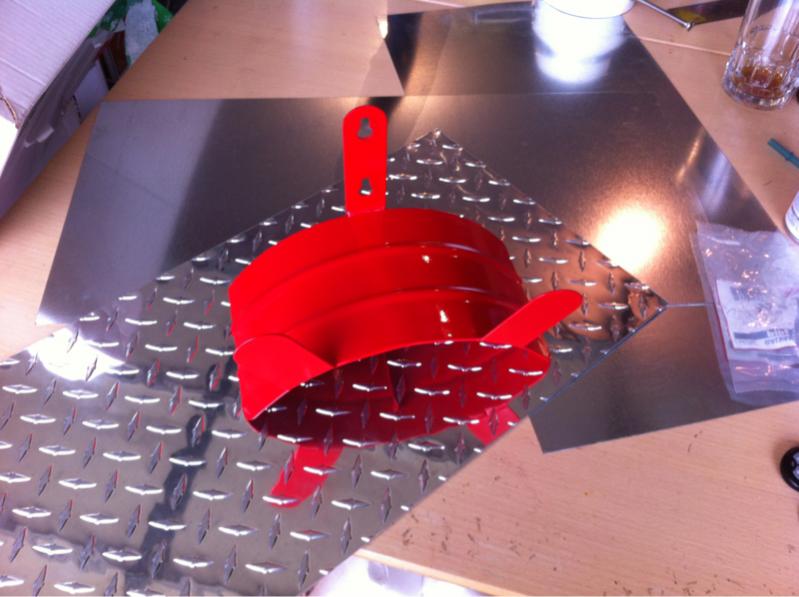

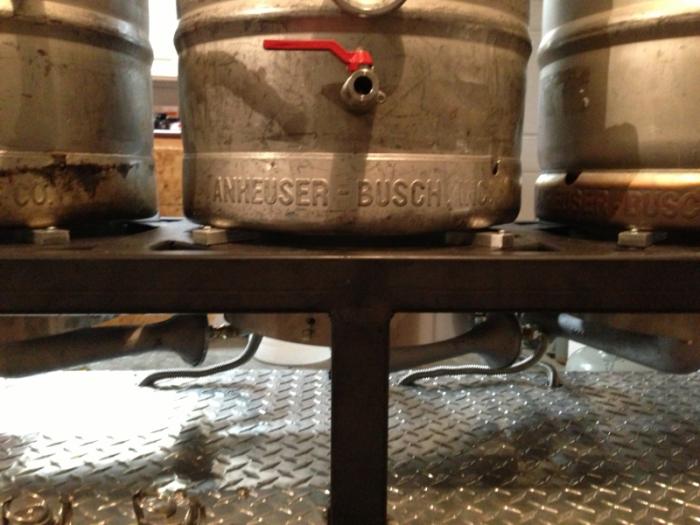

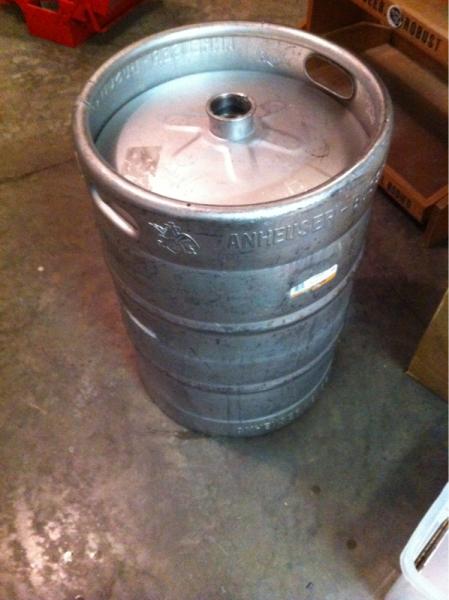

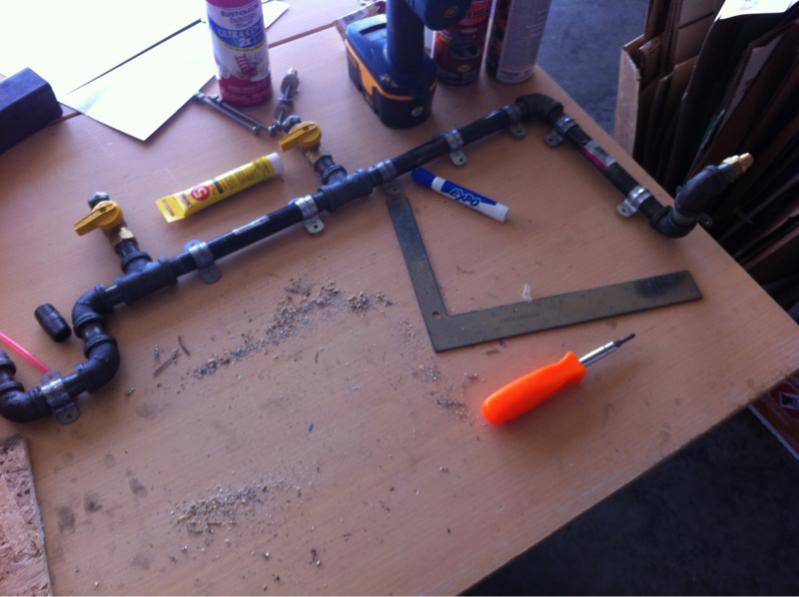

Decided to drill my mash paddle. Got my third keg and it is ready to be drilled. Also finished a little side project - my all stainless carbonation lid. Also got the casters on and there the kegs on there for fun. I hope to paint it today. Also started on my gas lines, and received my false bottom.

Decided to drill my mash paddle. Got my third keg and it is ready to be drilled. Also finished a little side project - my all stainless carbonation lid. Also got the casters on and there the kegs on there for fun. I hope to paint it today. Also started on my gas lines, and received my false bottom.