BraxtonBrewery

Well-Known Member

- Joined

- Sep 6, 2008

- Messages

- 104

- Reaction score

- 7

Brewtius Maximus/The Braxton 10 Complete Single Tier Build

Im going to try to document this whole build, but there may be some time between posts. Ill keep it updated as much as I can. Ive scoured the forums for different ideas, and Ive taken what I like and plan on building a combination of the things I like. Now its my time to post.

I brew on a simple wooden 3 tier gravity stand, very simple, but very tall:

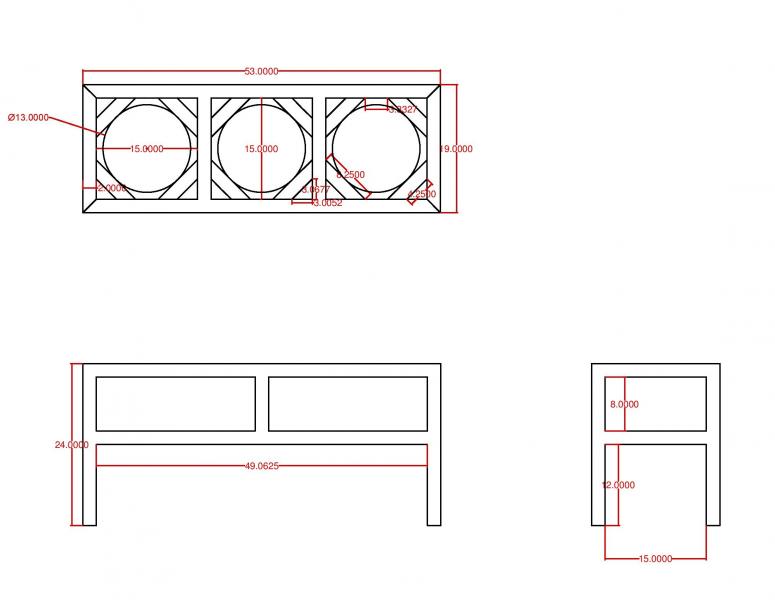

I made some pretty good beers on it, but it is time for a change. So I hopped on a few different design programs, and what I ended with can be seen here:

Front View

Angle view

The Back

Water Plumbing

The Bottom, with propane plumbing

With Kegs

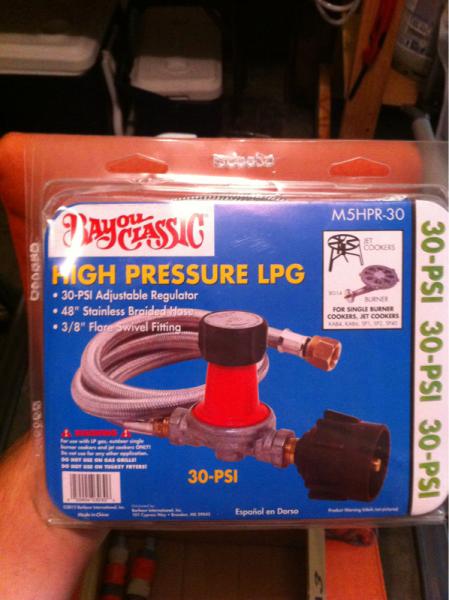

A single tier, 3 burner, 2 pump keggle stand. The propane and water will be hard plumbed, and the control panel will be a simple build, not much automation. A couple switches for pumps, igniters for the various burners and maybe a timer or two. I also thought that it would be nice to have a drawer and shelf for various things as well plus diamond plate looks sweet.

I have already ordered my pumps: 2 stainless steel inline Chuggers, and the plate chiller that BobbyM sells 30 plate long. These should arrive sometime this week, pictures upon arrival.I plan on ordering the steel within the next week, and my buddy and I are going to weld it.

Please feel free to give me your advice or ask any questions.

Im going to try to document this whole build, but there may be some time between posts. Ill keep it updated as much as I can. Ive scoured the forums for different ideas, and Ive taken what I like and plan on building a combination of the things I like. Now its my time to post.

I brew on a simple wooden 3 tier gravity stand, very simple, but very tall:

I made some pretty good beers on it, but it is time for a change. So I hopped on a few different design programs, and what I ended with can be seen here:

Front View

Angle view

The Back

Water Plumbing

The Bottom, with propane plumbing

With Kegs

A single tier, 3 burner, 2 pump keggle stand. The propane and water will be hard plumbed, and the control panel will be a simple build, not much automation. A couple switches for pumps, igniters for the various burners and maybe a timer or two. I also thought that it would be nice to have a drawer and shelf for various things as well plus diamond plate looks sweet.

I have already ordered my pumps: 2 stainless steel inline Chuggers, and the plate chiller that BobbyM sells 30 plate long. These should arrive sometime this week, pictures upon arrival.I plan on ordering the steel within the next week, and my buddy and I are going to weld it.

Please feel free to give me your advice or ask any questions.

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)