I tried something like this to get better efficiency and try and get the step mash temps to hit more accurately.

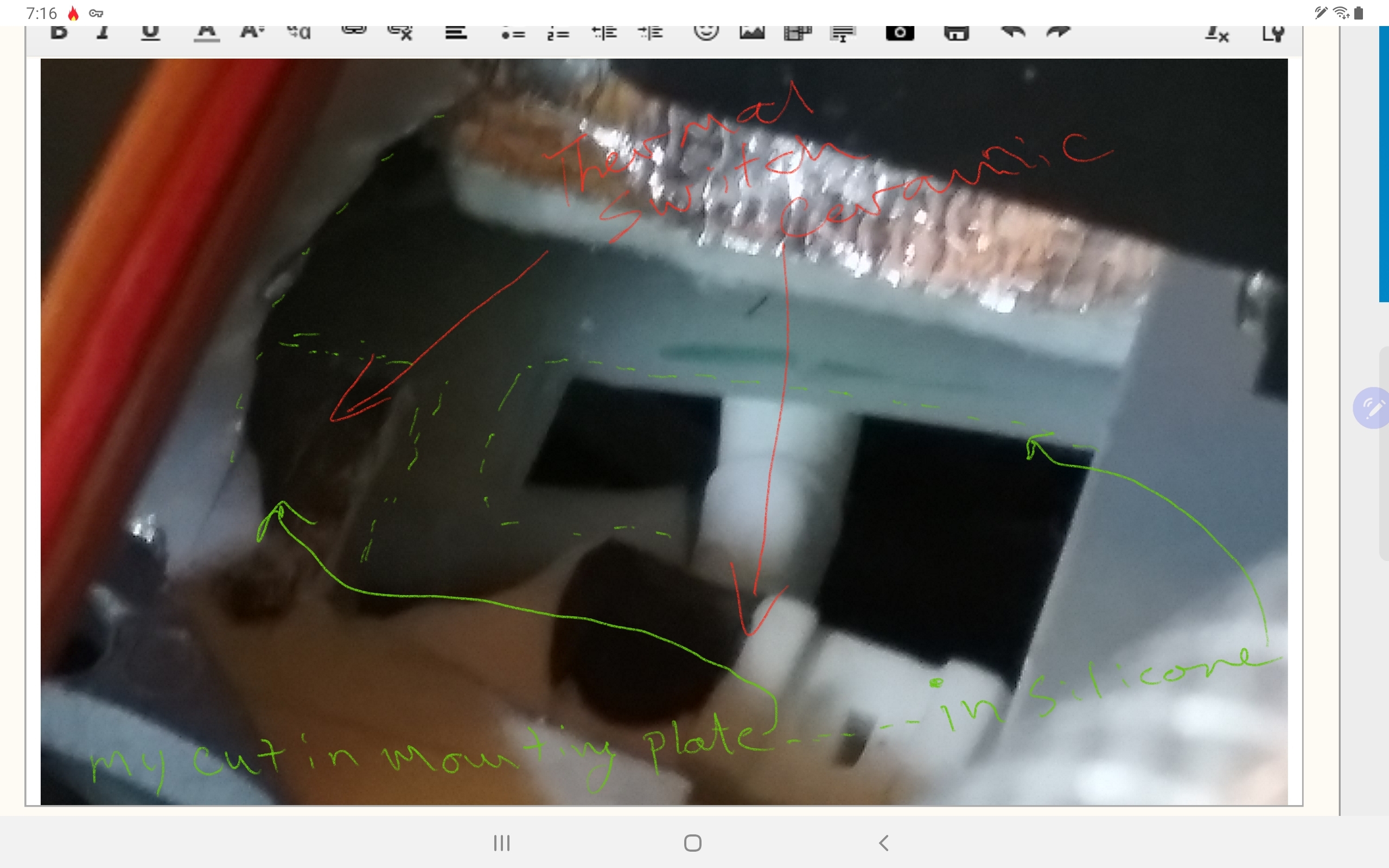

View attachment 651473

It was a first test run that didn't go perfectly. I 3d printed an elbow to fit into the mash inlet port and ran the hose up over the top. I used PETG which is generally regarded as food safe (think plastic water bottles) and prints at a higher temp than PLA or ABS. I thought it would hold up to the heat but it warped a bit and by the end it had cocked about 45* in the port and the flow to the top was significantly reduced. I think the next iteration may involve using some smaller tubing that will fit snugly into the port, cut at a 45* angle to allow the mash water flow (comes from the bottom in the brewie) and 3d print a 'sleeve' for it that will allow it to make the 90* vertical bend without kinking the hose closed.

I have just been doing single infusion mashes for the past few batches to ensure i hit conversion temps (mash in 8-10F higher than desired mash temp). I found that when doing step mashes, the mash water temp (measured by brewie) is not the same as the grain bed by a good margin. I would do 30-40 minutes steps and it would heat and progress through the steps allegedly, but the actual grain temps were always way way low. I think the mash inlet was bypassing a lot of the grain bed. By putting the liquid up top, its forced to go through the whole grain bed and heat the whole mash instead of just the water and malt at the bottom/sides.

I'd also like to get a fly sparge arm or sorts up there instead of the passive spreader, should improve the spray pattern and the vertical clearance issues (clearly couldn't shut the mash lid all the way with this).

I'll post again once i get the next iteration up and running.

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)