Thanks to

Rob Rowald for the google drive info, it made me confident enough to take the plunge on purchasing B20's.

I have picked up two of the ebay units, ordering the second one after the first one arrived with all of the accessories and in excellent physical condition. It also helped that ebay had a 10% bonus bucks promotion going both times.

In both cases the description stated:

This item is a customer return and has not been fully tested. For Parts Only.

Reported issue: Update Software

Visually we can report the following:

Cover: Looks Used

Tanks: N/A

Lids: N/A

An interesting item to note is the the serial numbers are sequential, almost like these were "remanufactured" units. Both came with all of the accessories, false bottom, hop cages, in what appears to be new condition since they were in what appears to be the original bags. One unit was running 2.9 the other 3.0.1. It appears that both of them have most likely been used, however very little. The second one appears to have not been used in about 14 months based upon the log files, had almost every tube had stuck together at the where the pinch valves had been closed. Both had the white silicon plugs placed per the service manual. I was also able to use the !#43373# to check if I could hear the pinch valves at least opening before I opened it up to swap out the sd card with new card with the 3.1.2 image. The menu looks identical to the developer mode in the videos. I found it in the service manual and have been using that as a guide for testing.

The tanks and sheetmetal in the first looked clean, I can see a line in the boil tank that makes it appear that it has been used before. The tubing looked clean, however the silicon plug on the outlet had some black film on it that easily wiped off.

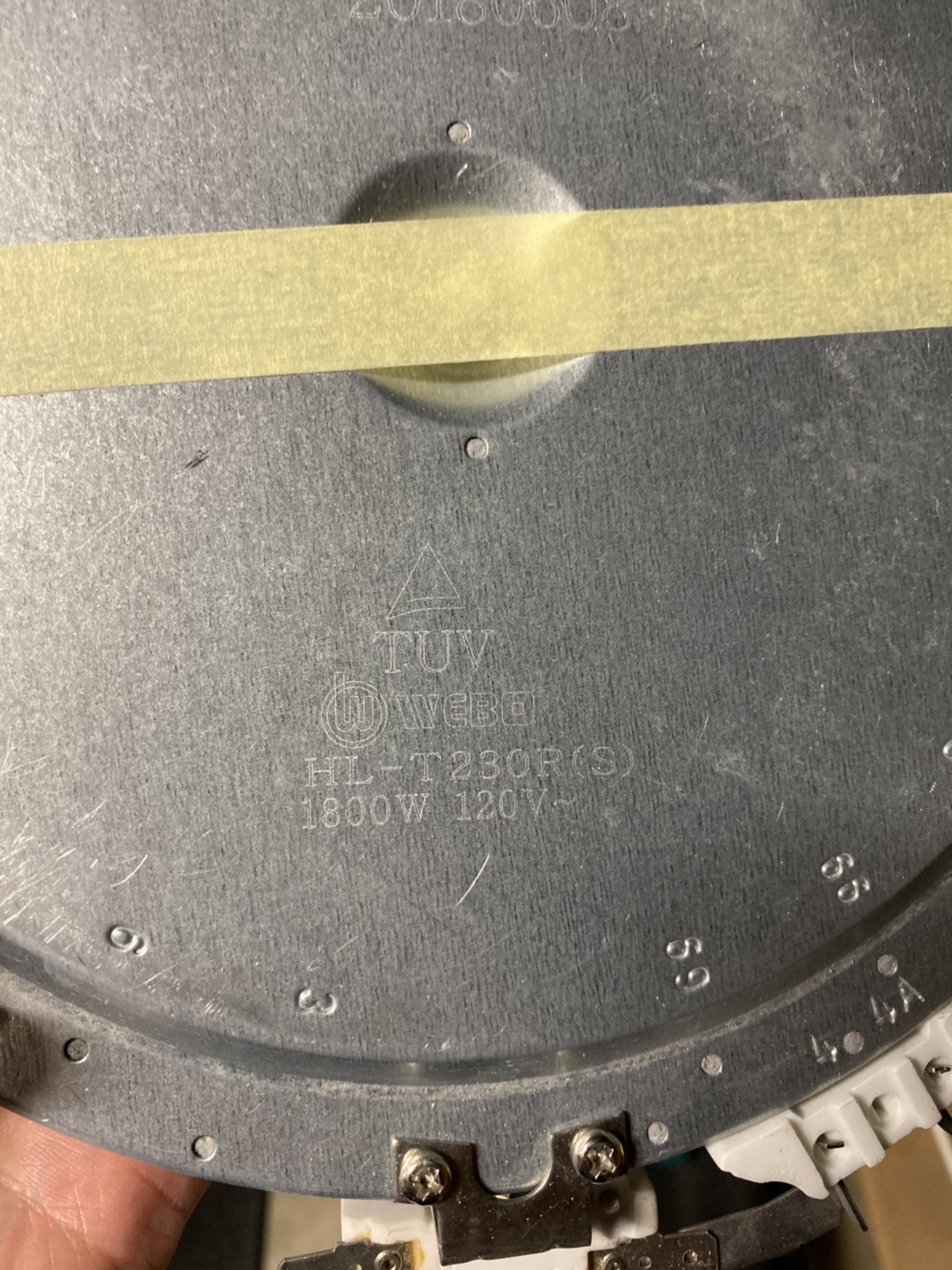

The second unit maybe had a mash tank dry fire, and then water poured in it since the bottom of the tank is warped/dented upwards over the right side of the heater. I can't figure out any other way that the bottom of the tank would be dented upwards, since dropping something into the tank would have dented it the other way.

So far happy with my two purchases. I have a pending order for replacement parts. I loaded it up more parts that I will probably need for the next 20 years and to allow me to replace pretty much everything, however the shipping on a $300 parts order came up to $95, so I have hesitated and am rethinking it. The replacement heating elements and entire front control panel's are somewhat large, but $95 seems crazy for shipping.

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)