HarkinBanks

Well-Known Member

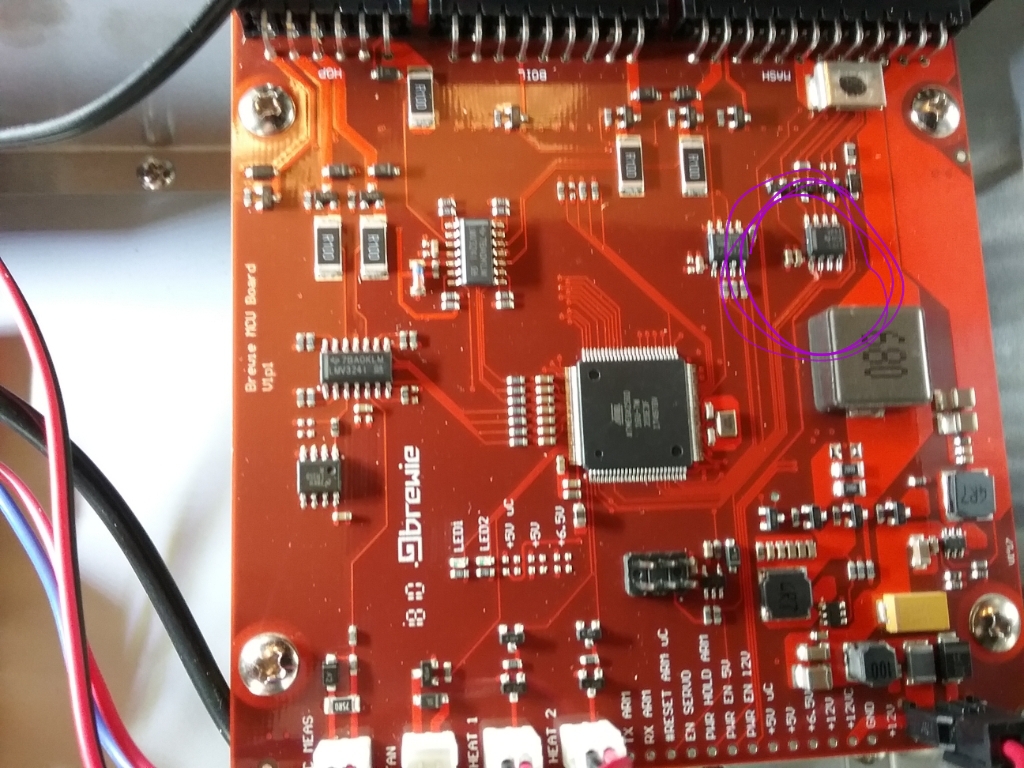

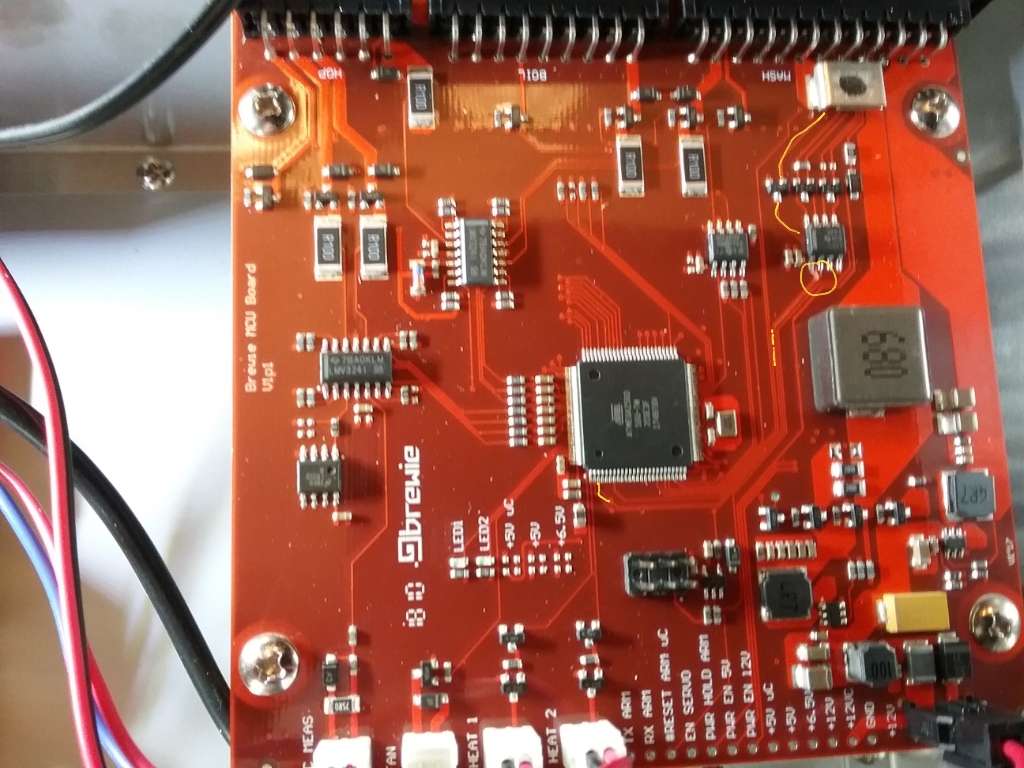

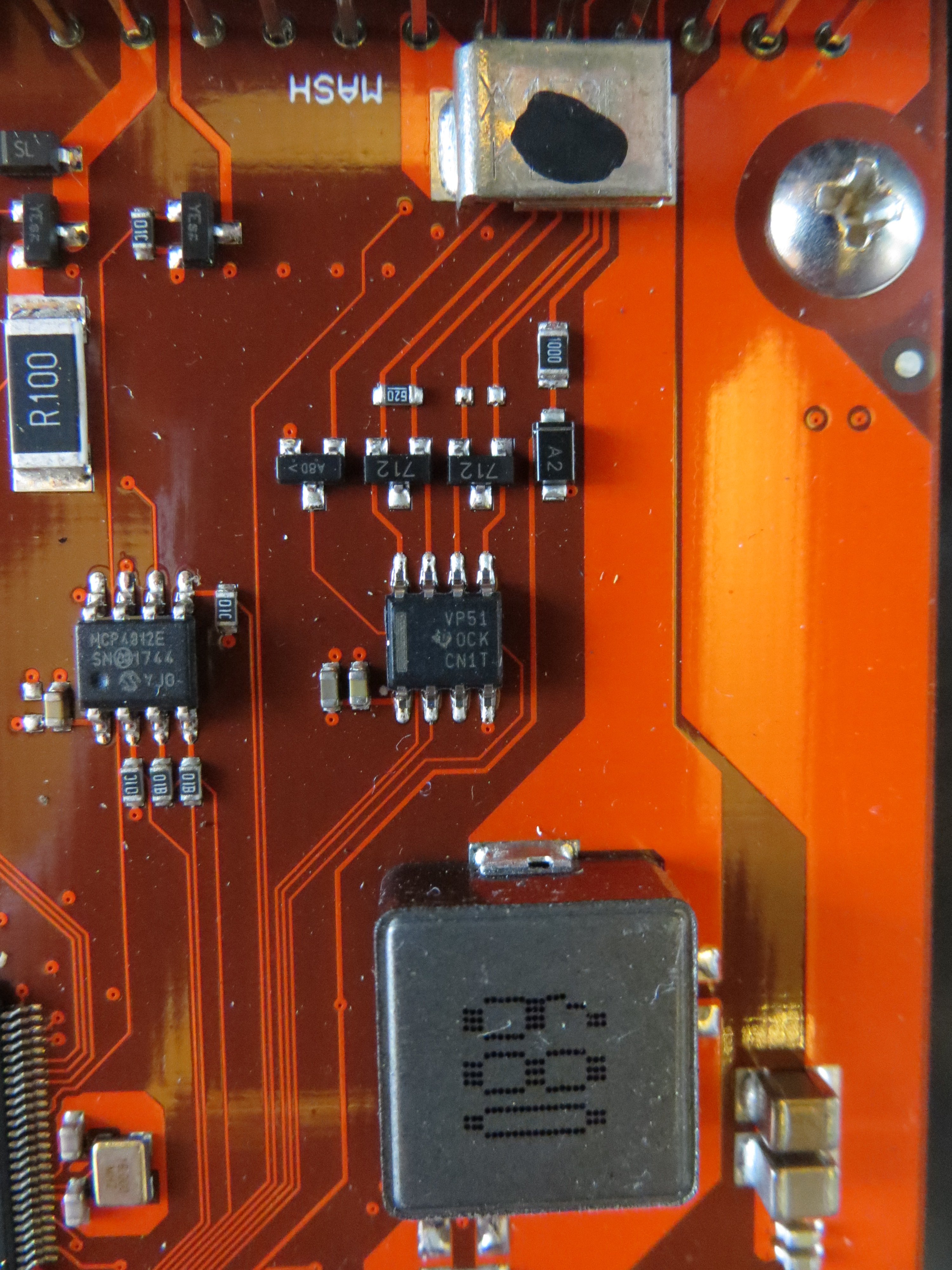

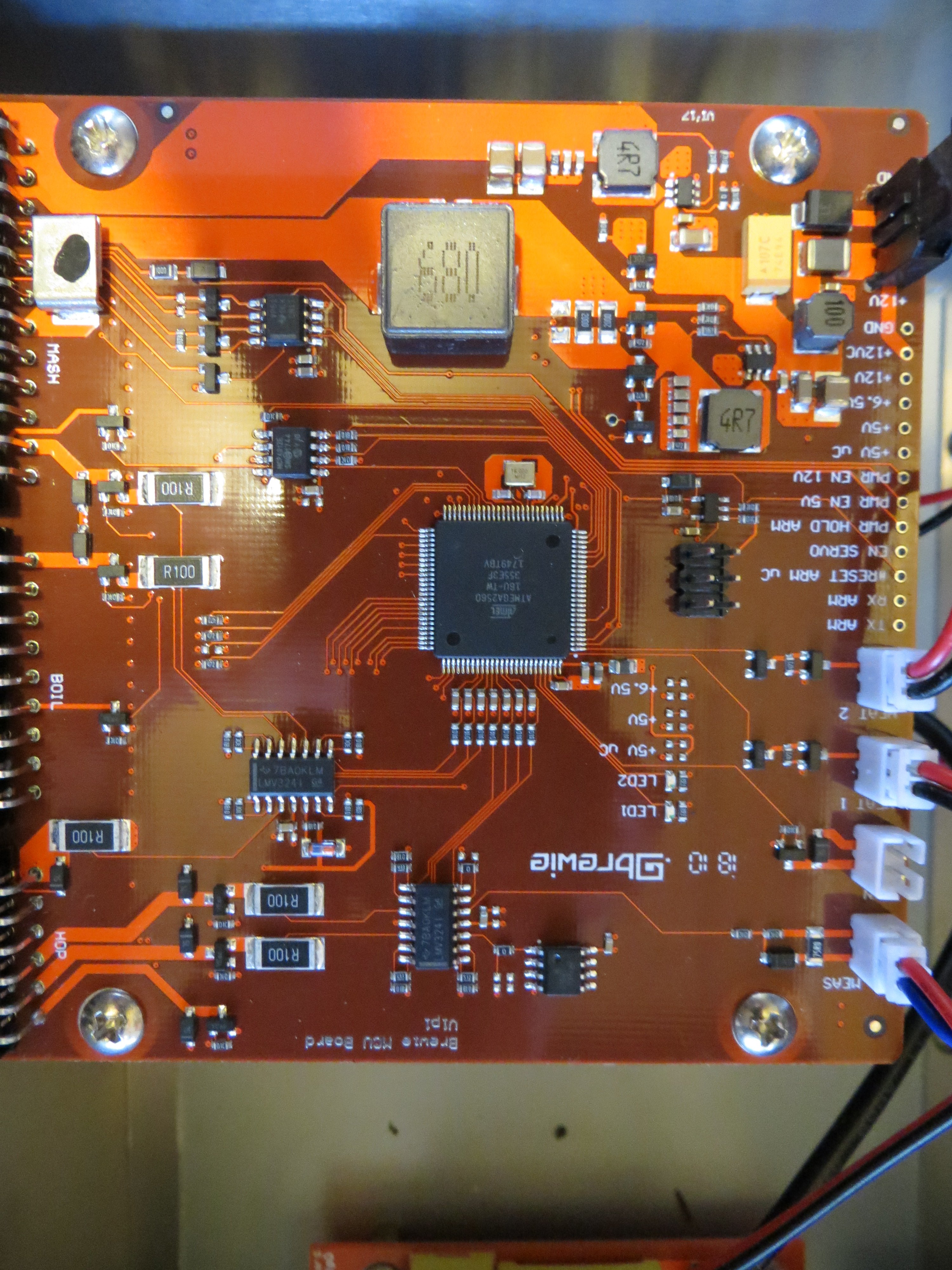

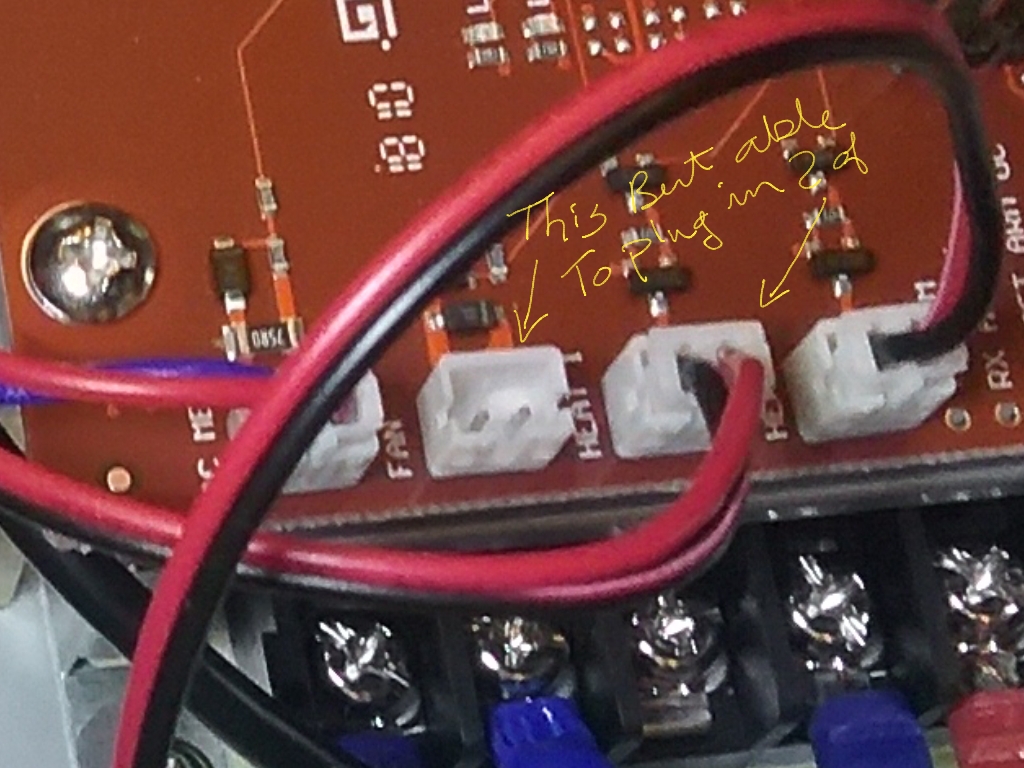

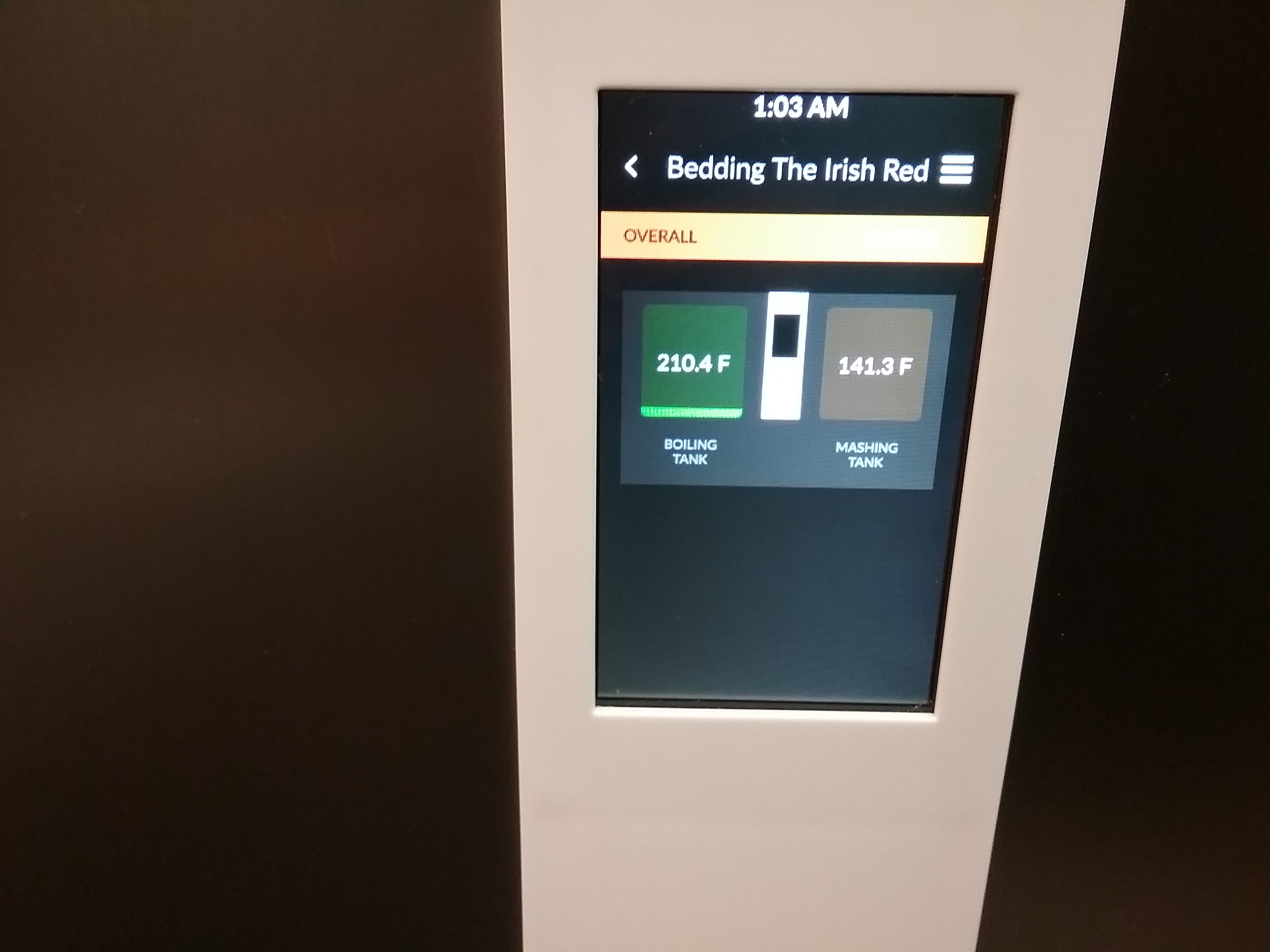

Found this link in another thread. Lots of info in the FCC filings and pics I had never seen before. This is for the B+ only:

https://apps.fcc.gov/oetcf/eas/reports/ViewExhibitReport.cfm?mode=Exhibits&RequestTimeout=500&calledFromFrame=N&application_id=JLdgqJqxCD+7ePP7bgRM5Q==&fcc_id=2ANZUB20

https://apps.fcc.gov/oetcf/eas/reports/ViewExhibitReport.cfm?mode=Exhibits&RequestTimeout=500&calledFromFrame=N&application_id=JLdgqJqxCD+7ePP7bgRM5Q==&fcc_id=2ANZUB20

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)