McKnuckle

Well-Known Member

I've been playing with BrewFather and it's quite a nice app in all respects! Easily the best UI and feature set I've seen so far (compared to the usual suspects).

However the efficiency math seems to be off, and I wonder if anyone else has noticed. Basically, if I plug in a given mash efficiency target into Brewfather, it makes both the pre-boil and original gravity estimates too high, usually by 4 or 5 points. To match other software, I have to crank down the Brewfather mash efficiency value by several percentage points.

I am a disciple of resident HBT efficiency guru @doug293cz , and I've incorporated his calculations into my own brewing spreadsheet. I'm not confused by the differences among conversion, lauter, mash, and brewhouse efficiency (just as a disclaimer). And I understand how these calcs use the dry grain weight, which perhaps not all of the popular software is aware of. However, even that, if removed from the equation, doesn't make the two agree.

As an example, take 12 lbs of American 2-row (37 ppg), mash it in 8 gallons of water, and pretend we'll get 100% conversion. Doug's calculations give a theoretical pre-boil gravity of 1.049 at 100% conversion efficiency. This produces a mash efficiency of 92%.

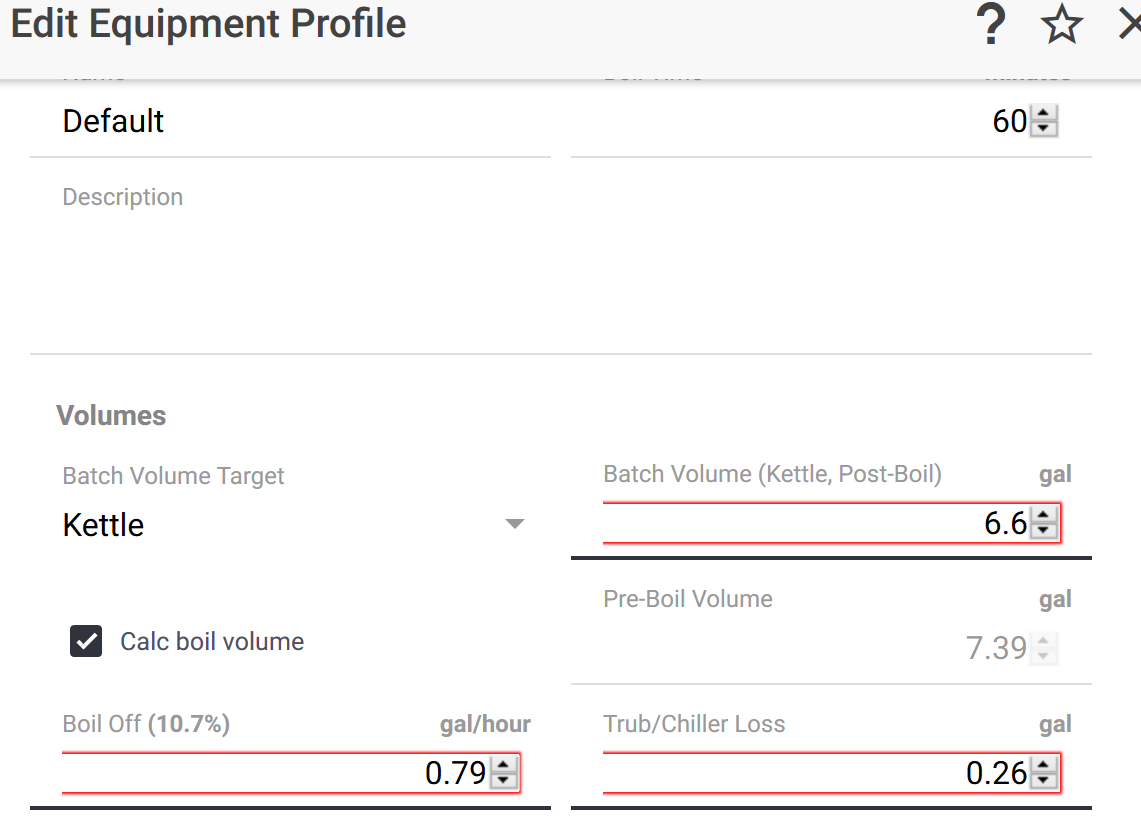

Brewfather doesn't have an input for conversion efficiency, so I have to input mash efficiency instead. If I put in 92% mash efficiency and zero out all losses to rule out other factors, the pre-boil gravity is predicted at 1.053. Naturally, the OG figures are off by at least that much as well.

With the dry grain weight factor removed, the numbers get closer by ~2 gravity points, but they still never match. I can't figure it out and it's driving me nuts!

However the efficiency math seems to be off, and I wonder if anyone else has noticed. Basically, if I plug in a given mash efficiency target into Brewfather, it makes both the pre-boil and original gravity estimates too high, usually by 4 or 5 points. To match other software, I have to crank down the Brewfather mash efficiency value by several percentage points.

I am a disciple of resident HBT efficiency guru @doug293cz , and I've incorporated his calculations into my own brewing spreadsheet. I'm not confused by the differences among conversion, lauter, mash, and brewhouse efficiency (just as a disclaimer). And I understand how these calcs use the dry grain weight, which perhaps not all of the popular software is aware of. However, even that, if removed from the equation, doesn't make the two agree.

As an example, take 12 lbs of American 2-row (37 ppg), mash it in 8 gallons of water, and pretend we'll get 100% conversion. Doug's calculations give a theoretical pre-boil gravity of 1.049 at 100% conversion efficiency. This produces a mash efficiency of 92%.

Brewfather doesn't have an input for conversion efficiency, so I have to input mash efficiency instead. If I put in 92% mash efficiency and zero out all losses to rule out other factors, the pre-boil gravity is predicted at 1.053. Naturally, the OG figures are off by at least that much as well.

With the dry grain weight factor removed, the numbers get closer by ~2 gravity points, but they still never match. I can't figure it out and it's driving me nuts!

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)