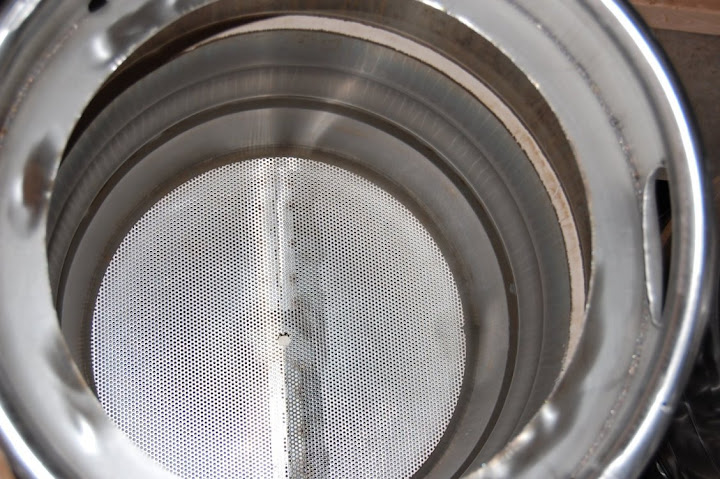

Make 10-15 gallon fermenters out of them. there's a guy on HBT that makes a tri-clover set up for them. Great use in my opinion. I turned another keg into a cooler for bbq's etc but now wish I had not cut the top off.

that would be http://www.brewershardware.com/fermenter.htm

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)