You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

BrewCommander - Impressive offering from John

- Thread starter BeardedBrews

- Start date

Help Support Homebrew Talk:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

Just out of curiosity what’s the logic for splitting the pump output? Just to make sure you don’t dry fire? Do you run pump on full blast with this setup?

It's pretty simple. The whirlpool keeps the heated area as mixed as possible so that as soon as the element puts any heat into the system, the probe nearby is picking up the average temp rather than a pocket of hot or cold. The recirculated portion of it goes through the grain to flush any cold areas downward to be heated again.

It does let you run a higher flow rate because only half of it has to get through the grain, but that's not the primary reason.

So I was thinking of moving temp probe to wort out valve? Would that help? I only have 2 low ports on my kettle. One is for heating element. The other is for the wort out valve.

I think it would be a slight improvement but it's not going to be rock solid.

I think it would be a slight improvement but it's not going to be rock solid.

so are you saying based on my existing ports and desire to brew single vessel I am not going to be able to get consistent mash temps? That is disappointing and now I am wondering what course of action to take next.

You can add another port under the bag for the probe and another one for low whirlpool. It's a pain in the butt, but that will solve your problem.

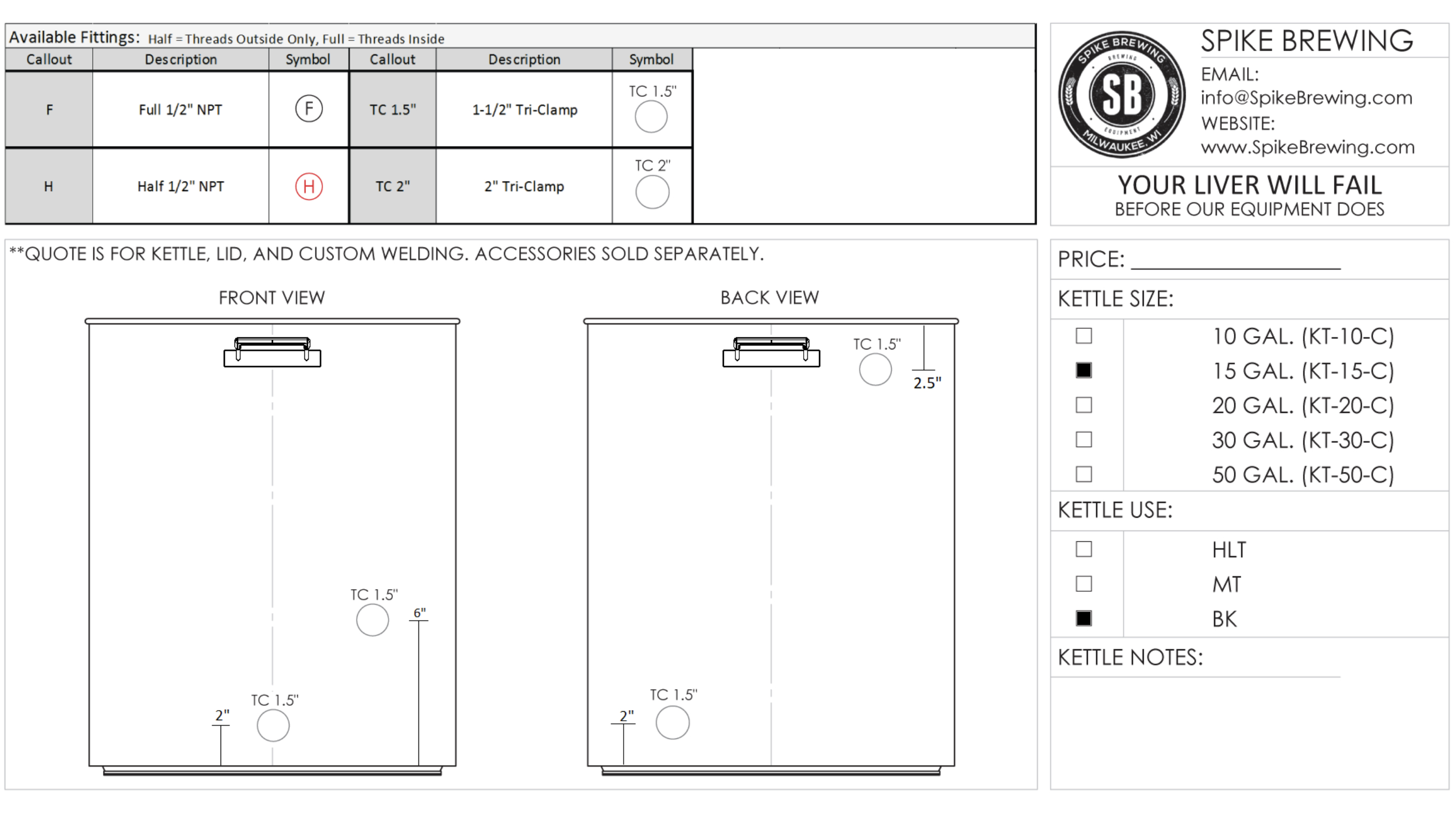

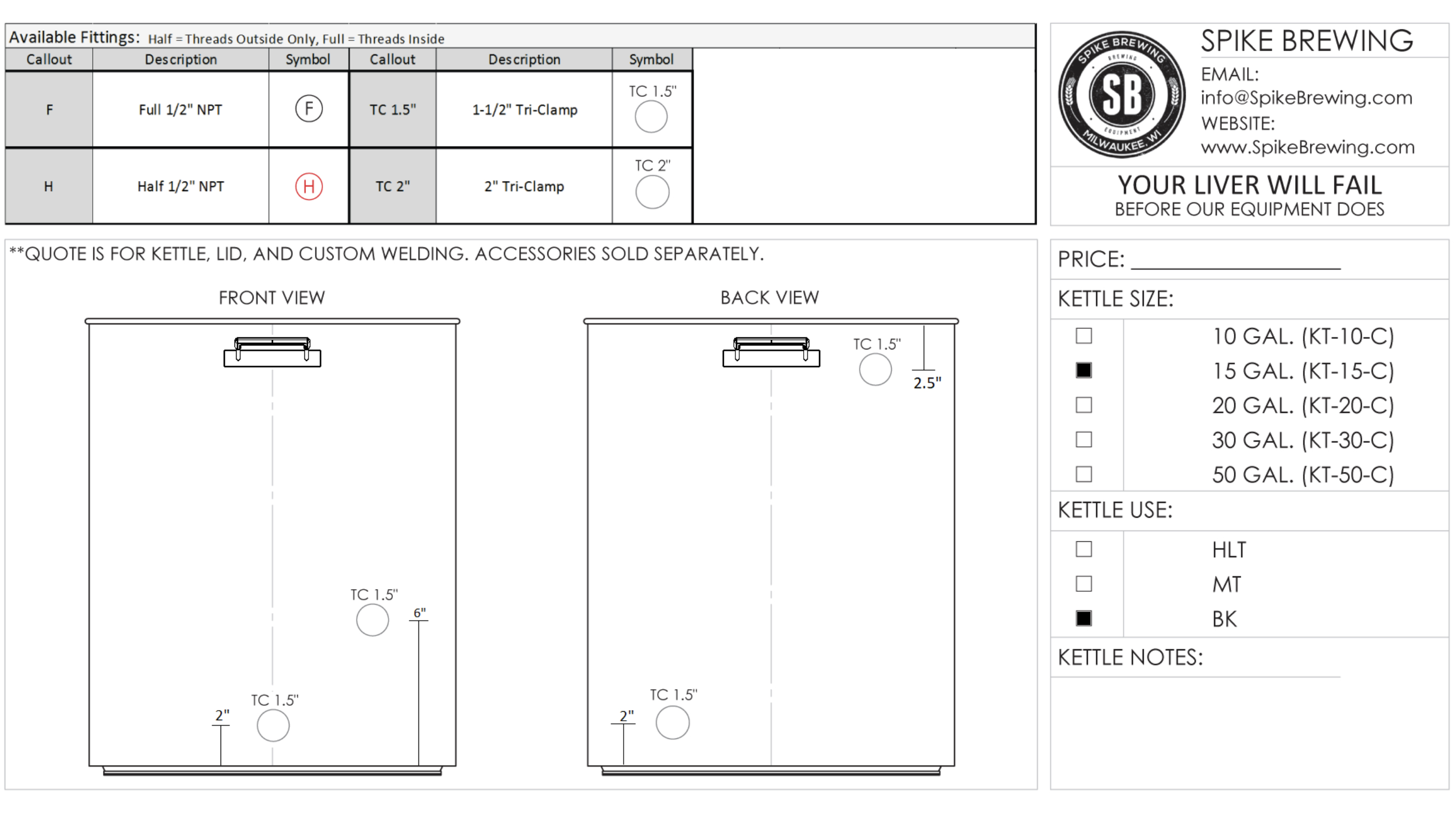

Here are the port placements on the BK. So adding another port about 2” of the bottom would solve the problem?

my other option is to try and go back to my original idea to use 2 vessels. I have a mash tun. However I was having efficiency issues trying to do 2 vessel and kind of gave up went back to BIAB. Never quite figured out best process for 2V even though it seems some others have.

my other option is to try and go back to my original idea to use 2 vessels. I have a mash tun. However I was having efficiency issues trying to do 2 vessel and kind of gave up went back to BIAB. Never quite figured out best process for 2V even though it seems some others have.

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)

$6.95 ($17.38 / Ounce)

$7.47 ($18.68 / Ounce)

Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]

Hobby Homebrew

$33.99 ($17.00 / Count)

$41.99 ($21.00 / Count)

2 Pack 1 Gallon Large Fermentation Jars with 3 Airlocks and 2 SCREW Lids(100% Airtight Heavy Duty Lid w Silicone) - Wide Mouth Glass Jars w Scale Mark - Pickle Jars for Sauerkraut, Sourdough Starter

Qianfenie Direct

$58.16

HUIZHUGS Brewing Equipment Keg Ball Lock Faucet 30cm Reinforced Silicone Hose Secondary Fermentation Homebrew Kegging Brewing Equipment

xiangshuizhenzhanglingfengshop

$76.92 ($2,179.04 / Ounce)

Brewing accessories 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304 Brewing accessories(Gas Hose Barb)

chuhanhandianzishangwu

$44.99

$49.95

Craft A Brew - Mead Making Kit – Reusable Make Your Own Mead Kit – Yields 1 Gallon of Mead

Craft a Brew

$20.94

$29.99

The Brew Your Own Big Book of Clone Recipes: Featuring 300 Homebrew Recipes from Your Favorite Breweries

Amazon.com

$479.00

$559.00

EdgeStar KC1000SS Craft Brew Kegerator for 1/6 Barrel and Cornelius Kegs

Amazon.com

$7.79 ($7.79 / Count)

Craft A Brew - LalBrew Voss™ - Kveik Ale Yeast - For Craft Lagers - Ingredients for Home Brewing - Beer Making Supplies - (1 Pack)

Craft a Brew

$176.97

1pc Commercial Keg Manifold 2" Tri Clamp,Ball Lock Tapping Head,Pressure Gauge/Adjustable PRV for Kegging,Fermentation Control

hanhanbaihuoxiaoshoudian

$53.24

1pc Hose Barb/MFL 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304(Liquid Hose Barb)

yunchengshiyanhuqucuichendianzishangwuyouxiangongsi

$22.00 ($623.23 / Ounce)

AMZLMPKNTW Ball Lock Sample Faucet 30cm Reinforced Silicone Hose Secondary Fermentation Homebrew Kegging joyful

无为中南商贸有限公司

$719.00

$799.00

EdgeStar KC2000TWIN Full Size Dual Tap Kegerator & Draft Beer Dispenser - Black

Amazon.com

$53.24

1pc Hose Barb/MFL 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304(Gas MFL)

Guangshui Weilu You Trading Co., Ltd

$49.95 ($0.08 / Fl Oz)

$52.99 ($0.08 / Fl Oz)

Brewer's Best - 1073 - Home Brew Beer Ingredient Kit (5 gallon), (Blueberry Honey Ale) Golden

Amazon.com

Yeah I personally loathe 2 vessel systems. Yes, you could get away with a whirlpool port at the same height as the drain for the whirlpool. You can save some money by installing the blichmann probe using their standards weldless bulkhead install method by drilling a 1/2" hole..... or yet another TC port to put the probe into.

RufusBrewer

Well-Known Member

I am a BIAB guy. I looked at a two vessel system. The only compelling reason I can see is to go 2 vessel would be to use a grain bill greater than what my BIAB set up can accommodate.

I guess another reason to go with a two a 2 vessel system might be if there something about a mash tun is more convenient or easier to deal with compared to lifting a bag of wet grain.

John Palmer calculates BIAB to be 78.0% and no sparge to be 70.7%. So I need to make a significantly higher OG and (and grain bill) to go in that direction.

Interesting, John Palmer calculates higher efficiency for sparges in metric units than imperial units. Somehow the mash knows if you weighed the grain and water in pounds/quarts as opposed to kilograms/liters.

I guess another reason to go with a two a 2 vessel system might be if there something about a mash tun is more convenient or easier to deal with compared to lifting a bag of wet grain.

John Palmer calculates BIAB to be 78.0% and no sparge to be 70.7%. So I need to make a significantly higher OG and (and grain bill) to go in that direction.

Interesting, John Palmer calculates higher efficiency for sparges in metric units than imperial units. Somehow the mash knows if you weighed the grain and water in pounds/quarts as opposed to kilograms/liters.

Nick Poggetti

Well-Known Member

Regarding the temp probe location discussion from the past page or two... I have the a boilcoil in my kettle, so installing the probe fitting down low would be awfully close to the element no matter where I rotate the location. Would that be a big deal?

Regarding the temp probe location discussion from the past page or two... I have the a boilcoil in my kettle, so installing the probe fitting down low would be awfully close to the element no matter where I rotate the location. Would that be a big deal?

I would put some kind of false bottom in there to create a cavity below the bag. Even if it's only 1" tall and sits in the interior of the boil coil, it's better than letting the bag sit on the bottom. It's the only way a recirculation is going to travel in a vertical laminar flow through the grain. If you do that, you can install the probe under that FB or at the very least, directly on drain.

Nick Poggetti

Well-Known Member

Right on. I have an old 10 gallon false bottom that fits just inside the 20 gallon boilcoil that should do the trick without needs to get something which I will give a go next batch. Thank you!

I've enjoyed using My BC, but temp readings have been way off in the kettle, I was having to do a 7 degree calibration adjustment to get it closer to other thermometers, boiling at 203..etc. tech support wasn't any help.

Today I try a factory reset and all is good.

it seems the rims offset of 8 degrees I had in advanced setting that I thought only applied during a mash threw off the temp reading no mater what I was doing. I guess you have to go in there and set it during the mash if you are using a herms, then zero it out during the boil or hlt heat up. Is this right? its annoying.

Today I try a factory reset and all is good.

it seems the rims offset of 8 degrees I had in advanced setting that I thought only applied during a mash threw off the temp reading no mater what I was doing. I guess you have to go in there and set it during the mash if you are using a herms, then zero it out during the boil or hlt heat up. Is this right? its annoying.

Wow, that doesn't sound right to me. What mode do you have in action during the boil? On or Auto? I would expect the RIMS offset to be factored in if you use AUTO but not "ON". However, that doesn't really solve the issue of heating up to strike unless you just remember to set the strike temp at temp minus offset.

Tested, reached set temp in auto. Plugged in 2 degrees rims, checked, BC immediately read 2 degrees low. I know it was way off on boil too. Seems to be right on now. I’ll have to test it in the “on” position to be sure

-in that mode though, I think BC stays heating at your set pwr % and doesn’t stop at a set temp

-in that mode though, I think BC stays heating at your set pwr % and doesn’t stop at a set temp

Two brews over the weekend. I left the rims field and calibration blank. All was perfect. Its easy enough to set your mash schedule and actual temp, hit play. Then bump up the temp as needed for your herms from the Home Screen

Silver_Is_Money

Larry Sayre, Developer of 'Mash Made Easy'

Can the 30A, 240 VAC Blichmann BrewCommander be used with a typical Camco 5500 Watt Ultra Low Watt Density heater element, or must it be used exclusively with a Blichmann BoilCoil heater element?

Sure. Just get the right plug.

RufusBrewer

Well-Known Member

Can the 30A, 240 VAC Blichmann BrewCommander be used with a typical Camco 5500 Watt Ultra Low Watt Density heater element, or must it be used exclusively with a Blichmann BoilCoil heater element?

The brewcommander is agnostic about what it will control. Voltage, current and power disapation is your concern.

And to reinforce wesbrew, make sure the power in socket and power out socket matches your existing or planned set up.

Anybody figured out how to get it to talk to the ssbrewtech ekettle temp probe?

They are probably different sensor technologies altogether.

mwayne112

Well-Known Member

Pretty sure I just had my second temp probe on the BC fail, that would be about 1 per year. Anybody know if there's a non Blichmann compatible probe?

beerbaron24

New Member

Modified for EU/AU/NZ/UK 240V

The 240V BC works perfectly with international 230-240 supply.

I also rewired the BC. Deleted the 110V input lead and took the pump 240V supply from the existing 240V. Wired a 240V output socket to feed the pump, fed through the old 110V grommet.

Even if your in US you could wire the controller this way and use a 240V pump to get rid of that extra power in cable.

Of course, Stay within the rated 30A, This probably voids your warranty. Only attempt if you know what you are doing. But this is a viable option for people outside of the US.

The 240V BC works perfectly with international 230-240 supply.

I also rewired the BC. Deleted the 110V input lead and took the pump 240V supply from the existing 240V. Wired a 240V output socket to feed the pump, fed through the old 110V grommet.

Even if your in US you could wire the controller this way and use a 240V pump to get rid of that extra power in cable.

Of course, Stay within the rated 30A, This probably voids your warranty. Only attempt if you know what you are doing. But this is a viable option for people outside of the US.

Last edited:

Modified for EU/AU/NZ/UK 240V

The 240V BC works perfectly with international 230-240 supply.

I also rewired the BC. Deleted the 110V input lead and took the pump 240V supply from the existing 240V. Wired a 240V output socket to feed the pump, fed through the old 110V grommet.

Even if your in US you could wire the controller this way and use a 240V pump to get rid of that extra power in cable.

Of course, Stay within the rated 30A, This probably voids your warranty. Only attempt if you know what you are doing. But this is a viable option for people outside of the US.

I've been offering this rewire service since the BC came out. Though in the U.S. most people are still using 120v pumps so the incoming wire is 4-wire 240/120v NEMA 14-30P and the only thing the neutral does is connect to the pump output receptacle. The circuit board is powered with 240v natively so the only unique thing coming in on that separate 5-15P is the neutral.

Similar threads

- Replies

- 4

- Views

- 3K

- Replies

- 1

- Views

- 958

- Replies

- 6

- Views

- 4K

- Replies

- 9

- Views

- 3K

- Replies

- 1

- Views

- 2K