tulsabrewdaddy

Well-Known Member

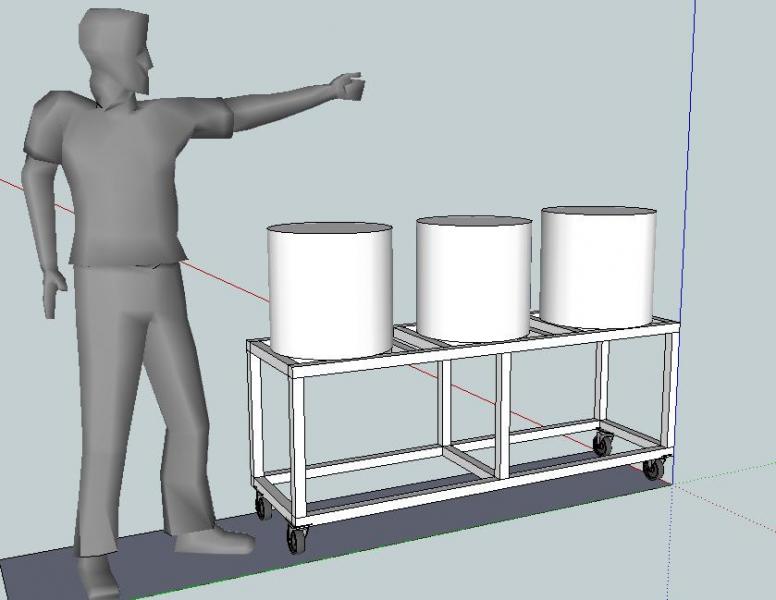

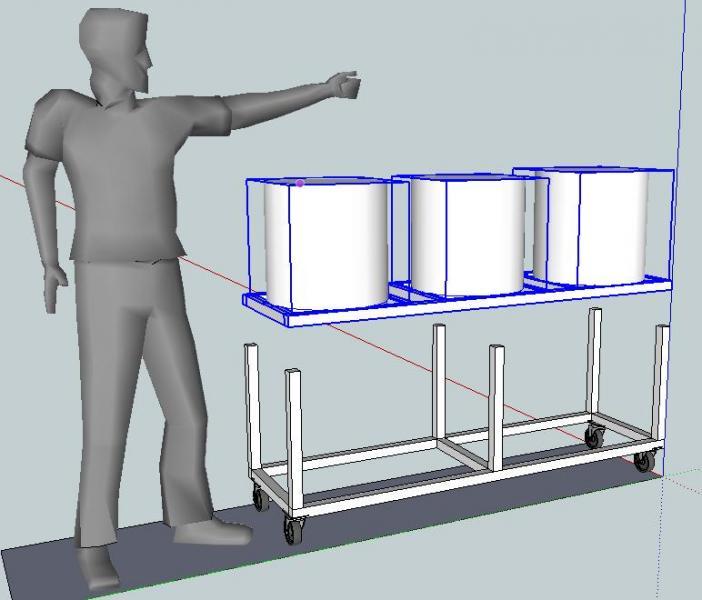

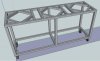

After originally going the weldless route for the stand with keggles. (I built the stand and had 2 kegs) I decided to go the welded route with pots. Here is what I have done so far:

Most of the pieces

Two 15 gallon pots

One 20 gallon pot

Conversions.....

Solder the couplers process

Digital temperature readout with switches for the pumps

more to come I'm planning on building the stand next weekend.

If you want more pics I've got them....

Most of the pieces

Two 15 gallon pots

One 20 gallon pot

Conversions.....

Solder the couplers process

Digital temperature readout with switches for the pumps

more to come I'm planning on building the stand next weekend.

If you want more pics I've got them....

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)